What is a fluid flow sensor?

A fluid flow sensor is an instrument used to measure the flow rate or volume of flowing gas, steam, liquid, or solids. Based on various physical principles, such as mechanical or electromagnetic, fluid sensors measure changes in the fluid and calculate the flow rate.

Fluid flow sensors can be divided into four categories based on the type of medium. They are used to measure and monitor the flow of gas, steam, liquid, or solids.

Below, we will show our available flow meters according to different media.

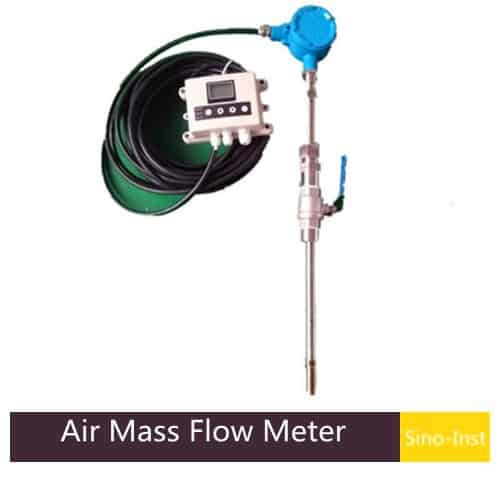

Fluid Flow Sensors for Gases

Common ones that can be measured include single gases, mixed gases, pressurized gases, etc. Below are some common measurable gases and applications that you can refer to.

- Oxygen, nitrogen, hydrogen, chlorine;

- Gas, air, nitrogen, liquefied petroleum gas, hydrogen peroxide, methane, butane, etc.

- Natural gas, liquefied gas, torch gas, compressed air and multi-component gas measurement;

- Aeration and fluorine gas measurement in biogas and water treatment;

- Gas in the production process of cement, cigarette and glass factories, carbon dioxide gas flow in the beer production process;

- Gas flow during the semiconductor chip manufacturing process;

- Gas flow measurement in solvent recovery systems;

- Blast furnace gas, coke oven gas, flue gas;

- Measurement of air in the gas process, calciner flue gas, and combustion gas in coal-fired boilers;

- Flue gas flow (velocity) measurement from the chimney (CES);

- Primary air, secondary air, mine underground ventilation or exhaust system flow of power plant blast furnace;

- Gas flow (G speed) measurement in heating ventilation and air conditioning systems;

The above gases are only part of our experience summary and cannot completely cover all gases. For specific Fluid Flow Sensor model selection, please contact us!

Please note:

The gases above is generally dry gas. If you need to measure humid gas, please consult our sales engineer separately.

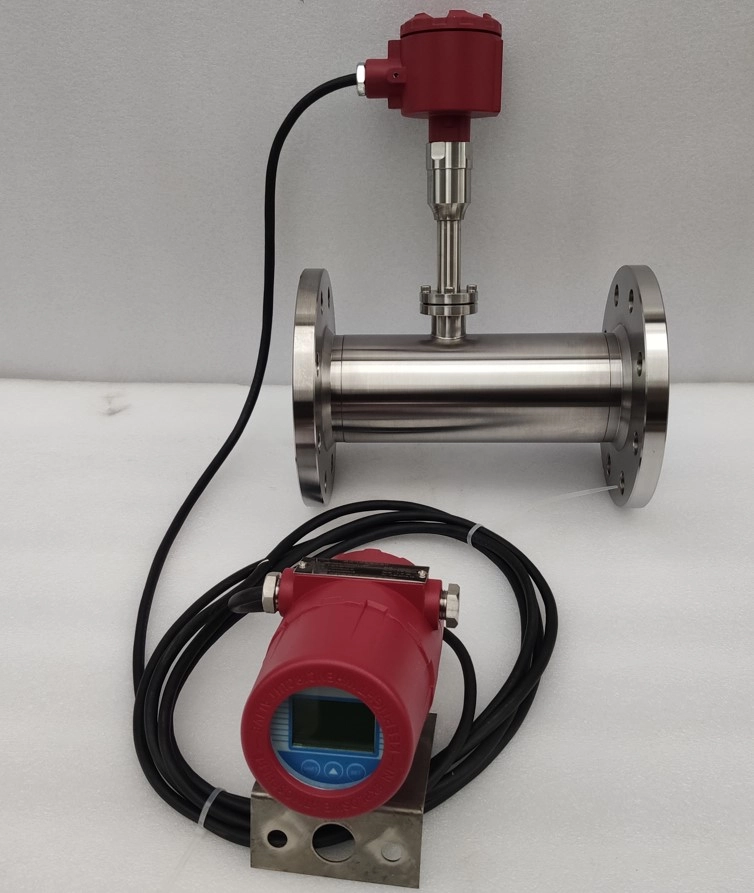

Fluid Flow Sensors for Steam

There are two types of steam: saturated steam and superheated steam. And measuring steam also involves high temperature, temperature and pressure compensation, etc. Therefore, when you choose a steam flow meter, please be sure to inform us of these parameters.

We also supply a Steam Pressure Sensor/transducer for Industrial Steam Measurement.

Fluid Flow Sensors for Liquids

Flow sensor selection for liquids is more complex than for gases and vapors. Because pipe diameter, flow rate, pressure, High temperatures, extremely low temperatures, viscosity, chemical properties, etc. will all affect the selection of Fluid Flow Sensors models.

You can refer to our “Flowmeter Selection Guide | Find the Best One for Your Application” and follow the steps to slowly select the appropriate model.

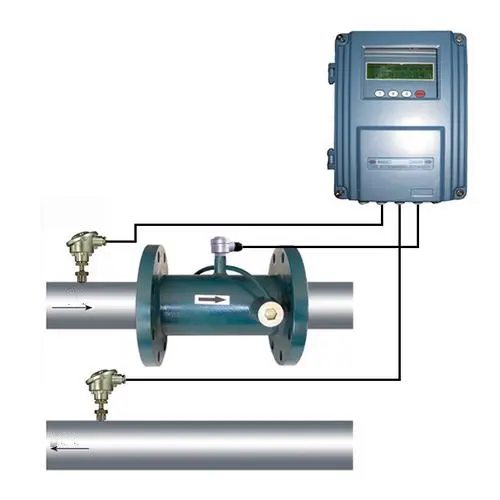

In addition to the above contact flow sensors, there are also unique non-contact flow sensors. The liquid flow can be monitored without changing the pipeline.

Fluid Flow Sensors for Solid/Powder

The powder flow meter can measure various bulk solid powder materials. Common ones include: food powder, coal powder, mineral powder, feed, lime, cement, carbon black, petroleum coke powder, etc.

Our Sino-Inst solid flow meter can be widely used in various industrial purposes, such as ironmaking, power generation, pharmaceutical machinery, chemical industry, building materials processing, cement manufacturing and other industries.

Typical uses include coal injection pipelines in ironmaking blast furnaces, coal injection pipelines in thermal power generation boilers, total process transportation volume monitoring, various fuel boilers and other productive powder flow monitoring.

What is a Flow Sensor / Flow Meter?

A Flow Sensor/Flow Meter is an instrument used to measure the flow rate of a fluid, such as a liquid or gas. The basic function of a flow meter is to measure the flow rate of a fluid.

This is critical for many industrial processes, as changes in flow rate may affect production efficiency and product quality.

In many industrial applications, flow meters are combined with control systems to monitor and regulate the flow of fluids in real time to ensure the stability and safety of the production process.

Types of Flow Sensors: by different operating principles

The content above this article classifies flow meters/flow sensors according to different media types. Then we can also classify flow sensors according to different measurement principles. From their names, you can see their working principles. Common classifications are as follows:

- Electromagnetic flowmeter. Used to measure the flow of various conductive liquids. Mostly used to measure water, wastewater, sewage, acid and alkali solutions, etc.

- Turbine flowmeter. Used to measure the flow of various clean liquids. Mostly used for low-viscosity liquids such as beer and diesel.

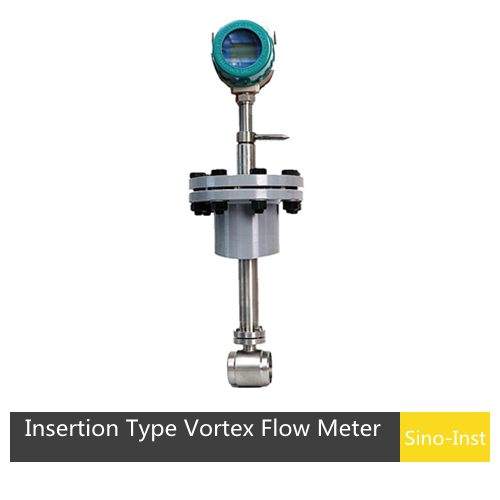

- Vortex flowmeter. Used to measure the flow of various gases, liquids, or steam.

- Ultrasonic flowmeter. Used to measure the flow of clean and impurity-free liquids.

- Positive displacement flowmeter. Including spiral rotor, dual rotor, oval gear, spur gear flowmeter, etc. Used to measure the flow of various oils and high-viscosity liquids.

- Differential pressure flowmeter. Used to measure the flow of various gases, liquids, or steam.

- Coriolis mass flowmeter. Highest measurement accuracy. Used to measure the mass flow of liquids or gases under various conditions.

- Thermal mass flow meter. Dedicated to measuring the flow of dry gases.

- Solid powder flow meter. Based on electrostatic measurement technology. Dedicated to measuring the mass flow of various powders.

Read more about flow sensors technology:

- Thermal Mass Flow Meter Technology

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flow Meter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

Benefits of Flow Sensors / Flow Meters

Choose Flow Sensors for Some Special Fluids

Case Studies

Case 1:

One of our customers wants to measure nitrogen flow. We configured a custom flange for it.

Thermal gas mass flowmeter

DN100

Nitrogen

DC24V/AC220V dual power supply

Output 4~20mA with RS485 communication

LCD displays instantaneous flow and cumulative total

Main body material 316

JIS 16K RF Japanese standard flange connection

Split type with 20m cable

Measuring range 28~2800Nm3/h

Temperature resistance 100℃

Pressure resistance 1.6MPa

Case 2:

Our customer wants to measure low-flow liquid (liquid R407C). We configured a low-flow special gear flowmeter for it.

Gear flowmeter

Model: GF02

Measuring range: 0.6-50L/H

Material: 316L

Temperature: -40℃ ~ +180℃

Pressure: 1.6Mpa

Explosion-proof display

G1/4 threaded connection

Signal output: Pulse + 4-20mA + HART

Case 3:

Our customers want to measure the flow of liquid under high pressure. We have configured high-pressure customized electromagnetic flowmeters of 42MPa and 16MPa for you.

Intelligent electromagnetic flowmeter.

Integrated DN50

Fluid type – industrial water (petrochemical)

Working pressure – 42MPA

Flow measurement range: 3.5~70m3/h

Working temperature – 0~70℃ (ambient temperature: -20℃~+50℃, relative humidity 5%~90%)

Pipe connection form – flange clamp type

Material: stainless steel 316L,

Output – 4-20mA

Power supply – 85~265VAC

Protection level: IP65

Mechanical vibration frequency: ≤55Hz, amplitude: ≤0.25mm

Measurement accuracy: ±1.0%

Display mode: LCD display

High-pressure electromagnetic flowmeter

DN40

Measuring range: 2-40m³/h (unit must be able to display L/min)

Temperature: 0-70℃

Pressure: 16MPa

Split type

Flange installation

24VDC, 4-20mA signal output

Inner lining: polyurethane

Measurement accuracy: ±1.0%

More Flow Measurement Solutions

In addition to our fluid classifications here, you can also learn more to purchase the most suitable flow meter.

- 11 Flow Meter Types and Their Advantages and Disadvantages

- Top 3 Flow Meters for PVC Pipes

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Volumetric Flow Meters: Comprehensive Guide and Product List

- Choosing the Right Inline Water Flow Meter

- Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

- Industrial Inline Flow Meters | Selection List

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- Top Guide to CO2 Flow Meters

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Top 3 Flow Meters for Oil

- Brewery Flow Meters for Beer and Wine | Electromagnetic and More

- Ultra Low-Micro Liquid Flow Measurement

- Use and Maintenance of Coriolis Mass Flowmeters

- Vortex Flow Meters for Natural Gas

- What Is the Flow Rate? Velocity vs Flow

- Insertion type flow meters

- Slurry & Sludge Flow Measurement

- High-Pressure Flow Meters

- Industrial Nitrogen Gas Flow Meters

- Industrial Liquid Nitrogen Flow Meters

- Flowmeters for Cryogenic Fluids Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Inline Compressed Air Flow Meters

- High Viscosity Flow Meters

- Diesel Flow Meter

- Digital Water Flow Meter

- Natural Gas Flow Meter

- Sanitary Flow Meter

- Wastewater flow meter

- Water Flow Meter Types

In addition to our fluid classifications here, you can also learn more to purchase the most suitable flow meter.

The above classification of Fluid Flow Sensors can help you choose the appropriate flow meter type simply and quickly. For specific models and configurations, you can confirm with our sales engineers!

-1.jpg)