Our flowmeter selection guide is designed to help you find the best flow meter for your application. Flow meters are one of the most commonly used instruments in industry.

Since flow is a dynamic quantity, the measuring instrument itself is affected by many factors, such as: pipe, diameter size, shape (circular, rectangular), boundary conditions, physical properties of the medium (temperature, pressure, density, viscosity, dirtiness, corrosiveness) etc.), the flow state of the fluid (turbulence state, velocity distribution, etc.) and the influence of installation conditions and levels.

Therefore, in the face of more than a dozen categories and hundreds of varieties of flow meters at home and abroad, how to make reasonable selection is the prerequisite and foundation for the good application of flow meters.

Our flow meter selection guide can help you quickly master the selection and application of flow meters.

Generally speaking, the analysis should mainly be carried out from the following 6 aspects:

- Measurement purpose;

- Fluid characteristics;

- Characteristics of flow meter;

- Installation requirements;

- Environmental conditions;

- Flow meter cost;

Measurement purpose

First of all, clarifying your measurement purpose is the key to choosing a suitable flow meter.

- For example, you need to detect the instantaneous flow of a pipeline and need local flow display.

- Or, if you need to detect the instantaneous flow rate and cumulative flow rate of the pipeline, you need to bring a calculator.

- Or, you need to conduct trade settlement through flow monitoring of pipelines. So high precision is very important.

- Or, you need to detect the flow, pressure and other parameters of the pipeline, and at the same time, you need to output the 4-20mA signal to the monitoring room.

- Or, you need to detect traffic parameters and store data.

Therefore, first you need to clarify the purpose of your traffic measurement and what effect you want to achieve.

Fluid characteristics

Common fluid physical properties include density, viscosity, vapor pressure and other parameters. These parameters can generally be found in the manual, and the suitability of each fluid parameter and the selection of the flowmeter can be evaluated under the conditions of use. But there are also some physical properties that cannot be found. Such as corrosiveness, scaling, clogging, phase change and miscible state, etc.

Detailed enumeration and description are as follows:

1.Fluid types:

The first thing that needs to be clarified is what fluid is being measured. Is the measured medium gas, liquid, or steam? And the measured fluid is single? Or mixed?

2.Density:

Density of FluidsFor liquids, the density is relatively constant in most applications. Unless the temperature changes greatly causing major changes, density correction generally does not need to be performed. In gas applications, the range and linearity of the flow meter depend on the gas density. Generally, it is necessary to know the values under standard conditions and working conditions for selection. There is also a method of converting flow state values to certain recognized reference values. This method is commonly used in petroleum storage and transportation. Low-density gases can be difficult for some measurement methods, especially instruments that use the momentum of the gas to push the detection sensor (such as turbine flowmeters).

3.Viscosity:

Required for liquids. The viscosity of various liquids varies greatly and changes significantly due to temperature changes. Gases are different. The difference in viscosity between various gases is small, and their values are generally low. And it will not change significantly due to changes in temperature and pressure. Therefore, the effect of viscosity must be considered for liquids.

4.Electrical conductivity:

Required for electromagnetic type flow meters. If the measured medium is liquid. Then it is best to confirm the conductivity of the fluid.

5.Contaminants:

Air bubbles, mixed-in foreign objects, slurry, etc.

6.Flow range:

It is best to confirm the minimum-normal-maximum flow rate in the pipeline. Can be mass flow rate or volume flow rate.

7.Fluid temperature and pressure:

Carefully analyze the working pressure and temperature of the fluid in the flow meter, especially if the temperature and pressure changes cause excessive density changes when measuring gas, the selected measurement method may need to be changed. For example, when temperature and pressure affect performance such as flow measurement accuracy, temperature or pressure correction must be made. In addition, the structural strength design and material of the flowmeter housing also depend on the temperature and pressure of the fluid. Therefore, the maximum and minimum values of temperature and pressure must be known exactly. Careful selection should be made when temperature and pressure vary greatly. It should also be noted that when measuring gas, it is necessary to confirm whether the volume flow value is the temperature and pressure under working conditions or the temperature and pressure under standard conditions.

8.Chemical corrosion:

The problem of chemical corrosion of fluids sometimes becomes a deciding factor in our choice of measurement method and use of flow meters. For example, certain fluids can corrode parts in contact with the flow meter, cause surface scaling or precipitation of crystals, and produce electrolytic chemical effects on the surface of metal parts. The occurrence of these phenomena will reduce the performance and service life of the flow meter. Therefore, in order to solve the chemical corrosion situation, a flowmeter made of anti-corrosion materials is selected.

9.Scaling situation:

Due to scaling or crystallization on the flow meter cavity and flow sensor, the clearance of the moving parts in the flow meter will be reduced, and the sensitivity or measurement performance of the sensitive components in the flow meter will be reduced. For example, in ultrasonic flowmeter applications, the scale layer will hinder the emission of ultrasonic waves. In electromagnetic flowmeter applications, the non-conductive scale layer insulates the electrode surface and makes the flowmeter unable to operate.

Characteristics of flow meters

Different types of flow meters have different advantages, disadvantages and performance parameters. For details, please refer to: 11 Flow Meter Types and Their Advantages and Disadvantages. Before we choose a flow meter, it is best to understand the performance parameters of various flow meters. Mainly from the following aspects:

Flow Meter Installation

Installation issues have different requirements for flow meters with different principles.

When using the flow meter, attention should be paid to the adaptability and requirements of the installation conditions, mainly considering the following aspects. For example, the installation direction of the flow meter, the flow direction of the fluid, the configuration of the upstream and downstream pipelines, valve positions, protective accessories, pulsating flow Impact, vibration, electrical interference and flow meter maintenance, etc.

- On-site pipeline wiring: When wiring on-site pipelines, attention should be paid to the installation direction of the flow meter. Since the installation direction of the flow meter is generally divided into vertical installation and horizontal installation, there is a difference in flow measurement performance between these two installation methods. of.

- Fluid flow direction: This problem is similar to the installation direction of the flow meter. Since some flow meters are stipulated to only work in one direction, reverse flow will damage the flow meter.

- Straight pipe sections upstream and downstream of the flow meter.

- Pipe diameter and pipe vibration: Some types of flow meters do not have a very wide range of pipe diameters, so being too large or too small will limit the choice of flow meter varieties.

- Installation position of the valve: Control valves and isolation valves are installed in the pipelines where the flow meters are installed. In order to avoid some flow velocity distribution disturbances and cavitations caused by the valves that affect the flow meter measurement, the control valve should generally be installed downstream of the flow meter. Installing the control valve downstream of the flow meter can also increase the back pressure of the flow meter and reduce the possibility of air pockets inside the flow meter.

- Protective accessories: Installing protective accessories is a protective measure to ensure the normal operation of the flow meter. For example, positive displacement flowmeters and turbine flowmeters generally need to install some necessary equipment such as filters upstream. All these equipment must be installed so as not to affect the use of the flowmeter.

- Electrical connection and electromagnetic interference: Most of the current flow measurement systems, whether the flow meter itself or its accessory connections, have electronic equipment, so the power supply used must be matched with the flow meter.

- Pulsating flow and unsteady flow: Pay attention to keep all installed flow meters away from the source of pulsation. The most common sources of pulsation include hydraulic oscillations such as fixed displacement pumps, reciprocating compressors, oscillating valves or regulators, and vortex columns. Generally, differential pressure flowmeters have pulsating flow errors, and turbine flowmeters and vortex flowmeters also produce pulsating flow errors. Unsteady flow refers to flow that changes with time and slow pulsation is a special case of unsteady flow. Such as the slow pulsation caused by the operation of an oversized control valve.

Environmental conditions

In the process of selecting a flow meter, surrounding conditions and related changes should not be ignored, such as ambient temperature, humidity, safety and electrical interference, etc.:

1) Ambient temperature

Changes in ambient temperature can affect the electronics and flow sensor portions of the flow meter. For example, temperature changes will affect changes in sensor size, and heat transfer through the flowmeter housing will change fluid density and viscosity. When the ambient temperature affects the electronic components of the display instrument, the component parameters will change.

2) Ambient humidity

The atmospheric humidity in the environment is also one of the problems that affects the use of flow meters. For example, high humidity will accelerate atmospheric corrosion and electrolytic corrosion and reduce electrical insulation, while low humidity will induce static electricity.

3) Security

The flowmeter should be selected in accordance with relevant specifications and standards to adapt to use in explosive hazardous environments, and on-site requirements should be carried out in accordance with explosion-proof standards.

4) Electrical interference

Power cables, motors and electrical switches will all produce electromagnetic interference. If relevant measures are not taken, it will become the cause of errors in flow measurement.

Flow meter cost

- Purchase cost of flow meter.

When purchasing a flowmeter, the economic impact of different types of flowmeters on the entire measurement system should be compared. For example, measuring water pipe flow, DN300 large diameter. Then the external clamp ultrasonic flowmeter will cost less than other flowmeters. - Installation and maintenance costs

When purchasing a flow meter, you must consider not only the purchase cost of the flow meter, but also other costs, such as accessory purchase fees, installation and commissioning fees, maintenance and regular testing fees, operating fees and spare parts fees.

Reference application guidance

Below is a summary of flow meter options for some common application types. For your preliminary reference:

| Liquids | Clean Liquid | Dirty Liquid | Abrasive /Slurry | Corrosive | High Pressure | Cryogenic | High Temp | Mass Flow | Low Flow Rates <0.1m³/hr (0.44gpm) | Low Conductivity | |

| Coriolis Flow Meter | ■ | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Magnetic Flow Meter (4-wire) | ■ | ■ | ■ | ■ | O | O | o | O | |||

| Magnetic Flow Meter (2-wire) | ■ | O | ■ | O | O | O | O | ||||

| Capacitance Magnetic Flow Meter | ■ | ■ | ■ | ■ | O | O | O | ■ | |||

| Vortex Flow Meter | ■ | O | O | ■ | O | ■ | ■ | ■ | ■ | ||

| Variable Area Flow Meter | ■ | O | ■ | O | ■ | ■ | O | ■ | ■ | ||

| Differential Pressure (DP)Flow | ■ | O | O | O | ■ | O | O | ■ | ■ | ■ | |

| Gas and Steam | Clean Gas | Dirty Gas | Corrosive | Low Pressure | Saturated Steam | Superheated Steam | Cryogenic | High Temp | Mass Flow | Low Flow Rates | |

| Coriolis Flow Meter | ■ | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ||

| Vortex Flow Meter | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ||

| Variable Area Flow Meter | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ||

| Differential Pressure (DP)Flow Meter | ■ | O | O | ■ | ■ | ■ | O | O | O | ■ | |

| ■ Designed for this service ; O Applicable for this service under certain conditions -consult manufacturer | |||||||||||

Selection examples

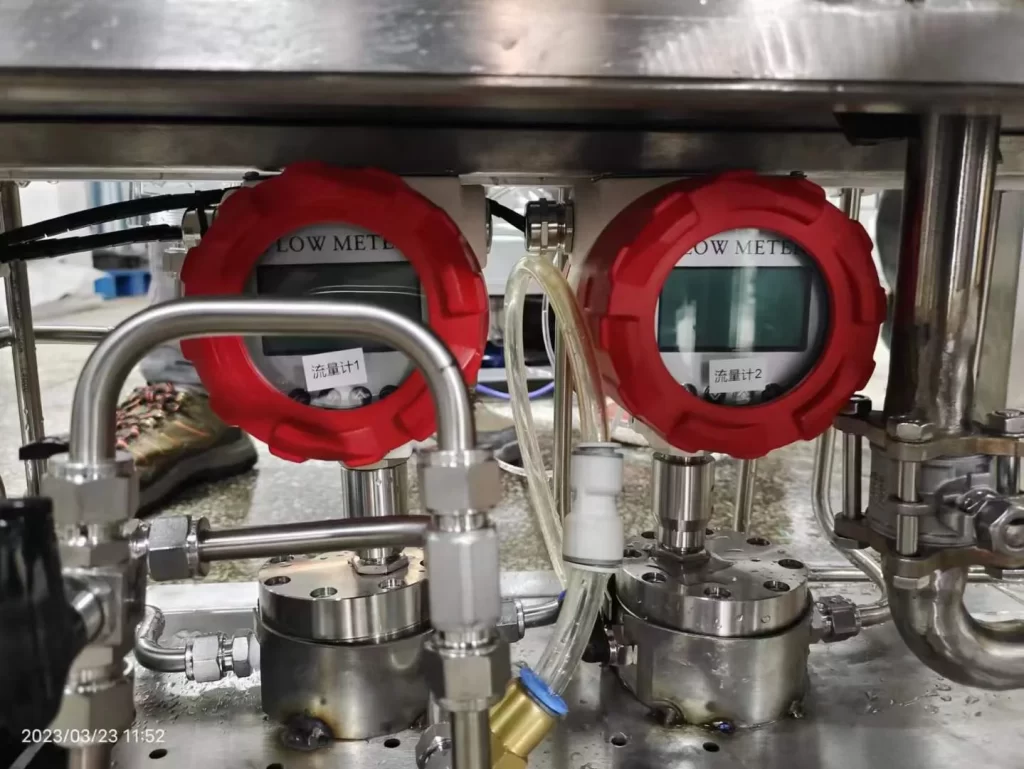

Refrigerant Flow Measurement for HVAC System

A customer from the United States was looking to purchase a flow meter to measure the flow rate of liquid R134A in their HVAC system. The system requirements and fluid properties were as follows:

- Fluid: Liquid R134A

- Connection tube size: 1/4″

- Flow rate: 5-250 L/h

- Operating temperature: -30°C to 150°C (-22°F to 302°F)

- Operating pressure: 0 to 600 psig

- Preferred output signal: 0-5V DC (alternative options: 0-10V DC, 4-20mA)

After evaluating various flow meter technologies, the customer selected our gear flow meter due to its suitability for their specific application. The gear flow meter provided accurate measurement for the refrigerant and met the temperature and pressure requirements. The selected gear flow meter had the following specifications:

- Model: GF-04

- Measuring range: 5-250 L/h

- Material: Stainless steel

- Connection: G3/8 thread

- Operating temperature and pressure: -30°C to 150°C (-22°F to 302°F), 0 to 600 psig

- Output signal: 0-5V DC

By choosing the gear flow meter, the customer was able to accurately measure and control the flow rate of liquid R134A in their HVAC system, ensuring optimal performance and energy efficiency.

More Flow Measurement Solutions

- Top 3 Flow Meters for PVC Pipes

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Top 4 Types of Pipeline Flow Meters-DN6~DN1000~DN6000

- Flow Measurement 101

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Volumetric Flow Meters: Comprehensive Guide and Product List

- Choosing the Right Inline Water Flow Meter

- Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

- Industrial Inline Flow Meters | Selection List

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- Top Guide to CO2 Flow Meters

- Ultrasonic Clamp on Flow Meter for Quick & Easy Measurements

Choosing the right flow meter for your application is critical to achieving accurate, efficient flow measurement. By considering the factors discussed in this Flowmeter Selection Guide and understanding the different flow meter technologies available, you can make an informed decision and find the product that best suits your specific needs.

As an experienced manufacturer and supplier, Sino-Inst offers a variety of flow meters and supports customization to meet your unique requirements.

Contact us today to discuss your flow meter needs and learn how our expertise can help you improve process control and efficiency.

-1.jpg)