Inline Compressed air flow meters are flowmeters for compressed air and industrial gasses.

Compressed Air Flow Meter is the digital flow meter work for the air compressor. Thermal mass, vortex, portable ultrasonic, and DP flowmeters are commom gas flow sensors. Air consumption is an important info for industrial inline gas flow pipe. Compressed air is the most expensive form of energy in manufacturing plants. And compressure air accounts for up to 20% of the overall energy costs. So, It is important to measure compressed air flows precisely in all conditions. This can improve the energy efficiency of compressed air systems while reducing costs. Sino-Inst offers compresses air flow meters with and without local display. And 4-20mA and 0-10v outputs and for hazardous area applications are available.

Featured Compressed Air Flow Meters

Sino-Inst manufactures compressed air flow meters.

Sino-Inst’s flow meters for compressed air precisely measure the compressed air outputs. Then system can pinpoint usage spikes, leakage rates and determine when service or upgrades are required.

A selection of flowmeters suitable for compressed air flow.

SI-3501 Thermal Mass Flow Meter for Compressed Air Flow

SI-3501 Thermal Mass Flow Meter is an instrument measures flow rate, according to thermal properties of gases. Detecting constant temperature difference of the medium, the flow meter can directly measure fluid mass flow, without requiring temperature and pressure compensation, to provide high accuracy measurement result.

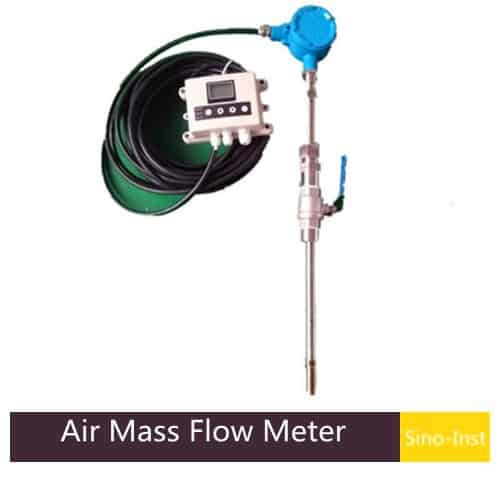

SI-3502 Air Mass Flow Meter for Compressed Air Flow

SI-3502 Air Mass Flow Meter, is the separated type thermal mass flow meter for air flow rate measurement. The mass flowmeters monitor flow, pressure, and temperature. Thermal mass flow meters are ideal for monitoring compressed air networks, meter the consumption, detect leakages and save costs. Besides the compressed air supply, the mass flow meters can also be used with non-corrosive and non-aggressive gases like oxygen, nitrogen or CO2.

SI-3503 Gas Mass Flow Meter for Compressed Air Flow

SI-3503 Gas Mass Flow Meter, is the flange type pipe thermal mass flow meter. Gas Mass Flow Meter is an ideal choice for the measurement of flow rates of a wide variety of gases. SI-3503 In-line type thermal mass flow meter, provides direct mass or standard volumetric flow measurement, for gas or air.

SI-3301 Gas Vortex Flow Meter for Compressed Air Flow

SI-3301 digital gas vortex flow meter is a flow meter operating with Karman Vortex principle for flow rate of gases (air, oxygen, nitrogen, coal gas, natural gas, chemical gas, etc.). It could be used in automatic control system as flow transmitter.

SI-3305 Intelligent Gas Precession Vortex Flowmeter for Compressed Air Flow

SI-3305 Intelligent Gas Precession Vortex Flowmeter is a new type of gas flow meter. It has the function of measuring flow, temperature, and pressure; it also can compensate temperature, pressure and compressible factor automatically. It is an ideal instrument of gas measurement, which is used for petroleum, chemical industrial, electricity, metallurgy, and so on.

SI-3201 GAS Turbine Flow Meter for Compressed Air Flow

Gas Turbine Flow Meter, is the flange type turbine flow meter. Turbine flow meter is the most popular equipment to measure flow electronically. They offer a wide flow and application rangeability. SI-3201 GAS Turbine Flow Meter, is perfect choice for natural gas flow rate measurement. Turbine flow meters are suitable for gas and liquid measurement. They offer a wide flow and application rangeability. Turbine Flow Meters are easy to installation, maintain, durable and versatile.

SI-3404 Ultrasonic Gas Flow Meter for Compressed Air Flow

SI-3404 Ultrasonic Gas Flow Meter is produced by advanced German technology. For Natural Gas flow measurement, this is a new type of precision measuring instrument, with high precision and better price. Easy installation for pipeline, widely applied to gas flow measurement.

SI-3701 Orifice Plate Flow Meter for Compressed Air Flow

SI-3701 Orifice Plate Flow Meter, is a high range specific differential pressure flow device, which is composed of standard orifice plate and multi-parameter differential pressure transmitter. (or differential pressure , temperature and pressure transmitter) It has simple structure, convenient maintenance and stable performance.

SI-3703 Verabar Averaging Pitot Tubes for Compressed Air Flow

SI-3703 Verabar Averaging Pitot Tube, one type of differential pressure flow meters, measuring the flow rate by differential pressure. SI-3703 Verabar Averaging Pitot Tube is developed on the basis of the principle of the pitot tube flow rate measurement. It can measure the flow of fluids such as liquids, gases and vapors. There is almost no pressure loss, installation and maintenance are convenient, and the running cost is extremely low, which is favored by users.

Compressed Air Flow Features

Compressed air is an important secondary energy source for enterprises and institutions. Compressed air is mostly converted from electrical or thermal energy by a compressor. When the air pressure value is low, it is generated by the blower. The management of working fluids converted from a large amount of energy is the main purpose of compressed air flow measurement. To achieve the effect of saving energy and improving equipment management.

In the chemical industry and other production processes. There is an important process oxidation reaction. It uses air as a raw material and chemically reacts with some other raw material under specified conditions. Too much and too little air mass flow will have a critical impact on safe production, product quality, and consumption of valuable raw materials. In this case, the accuracy of air flow measurement is particularly high, and it is also equipped with automatic adjustment.

Combustion processes in boilers and various industrial furnaces. Its essence is also the oxidation reaction, the measurement of combustion air flow. Although the accuracy requirement is not as high as the oxidation reaction in chemical production. But it is also of great significance for environmental protection, economic combustion and fuel conservation.

Characteristics of air flow measurement

① Large vibration. Not every air flow meter is installed in a place with high vibration. However, air flow meters installed in compression plants and blower rooms must consider vibration issues. This vibration comes mainly from compressors and blowers. The vibration of the machine can be transmitted far away through the air duct or air duct. Among them, the largest number of reciprocating compressors. The vibration generated during the operation of large reciprocating compressors often drives the plant to vibrate with the surrounding ground. Threats to the accurate and reliable operation of related air flow meters. It causes the fulcrum of the lever differential pressure transmitter to move and cause the indicator to drift. The vibration causes the vortex flow sensor to generate an interference signal corresponding to the vibration frequency, causing the flow indication value to be significantly higher.

② Gas carries water. Compressed air is taken from the atmosphere, which always contains a certain amount of water vapor. The content of water vapor is expressed by the partial pressure of water vapor ps. The saturated partial pressure of water vapor in the atmosphere is a function of atmospheric temperature. In rainy and foggy days, the partial pressure of water vapor in the outdoor atmosphere is saturated, that is, the relative humidity reaches 100%. Compressing the atmosphere at this time is like pressing a sponge that sucks up water. As the volume shrinks, a corresponding amount of water is precipitated. This is the simple principle that compressed air carries water. In fine weather, the relative humidity is low. But as it was compressed, the volume shrank to a fraction of its original size. The partial pressure of water vapor will increase accordingly, and it may enter into a saturated state and precipitate water droplets.

Large-diameter orifice plate flowmeter for measuring compressed air flow. There is often standing water in front of the orifice plate, which will affect the measurement accuracy. There is often a section of water in the impulse pipeline, which causes the differential pressure measured by the differential pressure transmitter to be inconsistent with the differential pressure generated by the throttling device. These are common causes of errors caused by water in the air. In addition, due to the high nitrogen oxide content in the urban atmosphere, water droplets contained in compressed air are acidic. Causes corrosion of the ring chamber surface and corrosion of the inner wall of the pipeline. Make it rough. When the iron oxide produced by corrosion becomes dry under certain conditions. It is easy to fall off the inner wall of the tube and be carried by the air flow in front of the orifice plate. This will also affect the flow indication. Therefore, during parking and maintenance, these powdery and lumpy garbage should be removed.

③ pulsating flow. Compressor and blower outlet fluids mostly contain certain pulsations. Reciprocating compressors, for example, appear as half-wave pulsations. Obvious fluctuations in the outlet pressure of the compressor and blower can be observed at the scene. Among them, the positive (fixed) displacement blower outlet pulsation frequency is relatively high, generally tens of hertz. And the reciprocating compressor outlet pulse frequency is relatively low, generally a few hertz. Flow arterial motion caused a variety of flowmeters such as differential pressure flowmeters, vortex flowmeters, etc. to show high values. Causes the float in the float flow meter to jump up and down. There are two commonly used methods to eliminate and reduce the effect of flow arterial motion on the flowmeter display value. One is to set a buffer tank at the compressor outlet to filter out the pulsation, and install the flow meter behind the buffer. In fact, the systems of reciprocating compressors are designed in this way. The second is to install the flow meter away from the source of the pulsation. In this way, the air volume of the process pipe and its pipe resistance can be used to form a low-pass filter attenuating the pulsation.

What device measures air flow?

An Air Flow Meter is the flow meter that measures industrial air velocity. Most of the time, people talk about air flow meters means compressed air flow meters. We are discussing here all air flow meters, including compressed air flow meters. Depending on the type of application, the Air Flow Meter is made as a hot-wire, a vane, a cup anemometer, a Pitot tube flow meter. All air flow meters can measure air velocity as well as air pressure. The most common unit of measurement for air flow is m/s.

Ultrasonic Carmen Vortex Air Flowmeter

Hot wire air flow meter works

Hot film air flow meter

Mass Air Flow Meter

A thermal mass flow meter is a precision instrument. Thermal mass flow meter measures gas mass flow and is used in various industries. For direct mass measurement of industrial gases, compressed air, and aqueous fluids.The flowmeters indicate the mass flow or normalized volume flow of gases. Thermal mass flow meter measures without any additional pressure and temperature compensation.

Thermal mass flow meters have impressively high accuracy, short response time and a very wide flow range. With virtually no loss of accuracy even at the lowest flow rates. High turn down or low-pressure losses are important in gas metering applications. Thermal mass flowmeters offer a real alternative to traditional measuring techniques. Whether for process control, consumption and supply monitoring, detecting leaks or monitoring distribution networks.Using insertion versions, it is also possible to measure gas flows in very large pipelines or in rectangular ducts.

Compressed air flow meter working principle

Vortex meters use a shedder bar, to generate the phenomenon known as Kármán vortex street. In which vortices begin to form and oscillate. Using a variety of sensor technologies, the natural frequency of these oscillating vortices is converted into a digital signal. Then processed through the meter’s electronics to calculate flow. More…

A turbine flow meter is used for volumetric total flow and/or flow rate measurement. Turbine flow meter has a simple working principle. As fluid flows through the turbine meter, it impinges upon turbine blades. These blades are free to rotate about an axis along the center line of the turbine housing. The angular (rotational) velocity of the turbine rotor is proportional to the fluid velocity. The resulting output is taken by an electrical pickoff(s) mounted on the flow meter body. More…

Best way to measure compressed air flow

Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity.

Even for the steam flow rate, Vortex flow meters are the perfect choice. Pressure and Temperature compensation ensure measurement accuracy. When measure steam or gas flow in pipes with variable operating pressure and temperature.

Applications in the chemicals and petrochemicals industries. For example, in power generation and heat-supply systems. Involve widely differing fluids: saturated steam, superheated steam, compressed air. Nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water. Solvents, heat-transfer oils, boiler feedwater, condensate, etc.

Compressed air flow meter price

The price of Compressed air flow meters are decided by flollowing factors:

Pipe diameter;

Flow range;

Measured medium;

Whether it is corrosive;

Whether explosion protection is required;

Whether it needs local display;

Connection method;

Measure pressure;

Measure temperature;

Signal output;

Accuracy requirements;

Material requirements;

Important factors when selecting flow metering devices are:

accuracy

cost

legal constraints

flow rate range

head loss

operating requirements

maintenance

lifetime

These factors are more or less related to each other. Example – the cost of flow meters increases with accuracy and lifetime quality.

Techincal Support

The measurement principle of various flow meters is different.

But no matter what kind of flowmeter, the flow needs to be converted into pressure (pressure difference), force, position, pulse, etc.

This pressure (pressure difference), force, position, pulse, etc., which represents the flow, is converted into the same Specifications for remote transmission signals.

The second conversion mentioned above is the function of the transmitter.

When the two conversions are completed in one device. Or two devices are completed, but collectively referred to as the two devices. It is called a flow meter or flow transmitter.

When the two conversions are completed by two devices, they are called (flow) measuring elements and transmitters. Among them, the transmitter has a differential pressure transmitter, a pulse transmitter, etc. According to the different signals from the measurement elements.

A flow meter, also called flow sensor, is a device or an instrument used to measure linear, nonlinear, mass or volumetric flow rate of a liquid or a gas.

Flow Metering Principals

Differential Pressure Flowmeters

Velocity Flowmeters

Positive Displacement Flowmeters

Mass Flowmeters

For Open Channel Flowmeters – weirs, flumes, submerged orifices, current meters, acoustic flow meters and more

For different working principle, We offer different types of flow meters, like:

Differential Pressure Flow Meters

Orifice Plate

Venturi Tube

Flow Nozzles

The Sonic Nozzle – Critical (Choked) Flow Nozzle

Calorimetric Flowmeter

Ultrasonic Doppler Flowmeter

Positive Displacement Flowmeter

Variable Area Flowmeter or Rotameter

Velocity Flowmeters

Pitot Tubes

Turbine Flowmeter

Thermal Flowmeter

Coriolis Flowmeter

Mass Flowmeters

Open Channel Flowmeters

Diesel flow meter – Turbine Flow Meter Solution

Diesel flow meter is the inline Turbine flow meter dedicated to measure diesel fuel flow. The diesel flowmeter uses a Turbine to measure. It first converts the flow rate to the speed of the turbine. And then converts the speed into an electrical signal that is proportional to the flow. This flow meter is used to detect the instantaneous flow and the total accumulated flow. Its output signal is frequency, which is easy to digitize.

High Viscosity Flow Meters

High viscosity flow meter is the flow meter measures the flow rate of viscous fluid flow. Common high viscosity liquids are: Crude oil, diesel, heavy oil. Asphalt, paraffin, honey, methanol, crude benzene, resin, and polyvinyl alcohol. Common high viscosity flow meters are: Oval Gear flow meters. Mass flow meter, Target flow meter, and Wedge flow meter also works for viscousity liquids.

Turbine Flowmeter Technology

A turbine flow meter is a Volume flowmeter. Turbine flow meters use the mechanical energy of the liquid or gas to rotate a rotor in the flow stream. The velocity of the turbine rotor is proportional to the velocity of the fluid passing through the flow meter. The frequency of the signal relates directly to flow rate. The vaned rotor is the only moving part of the flow meter. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, diesel, water, cryogenic liquids, air, and industrial gases. Turbine flow meter is the most popular equipment to measure flow electronically. They offer a wide flow and application rangeability. Turbine Flow Meters are easy to maintain, durable and versatile.

Vortex Flowmeter Technology

Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity. Even for the steam flow rate, Vortex flow meters are the perfect choice. Pressure and Temperature compensation ensure measurement accuracy. When measure steam or gas flow in pipes with variable operating pressure and temperature. Applications in the chemicals and petrochemicals industries. For example, in power generation and heat-supply systems. Involve widely differing fluids: saturated steam, superheated steam, compressed air. Nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water. Solvents, heat-transfer oils, boiler feedwater, condensate, etc.

-1.jpg)