Water pressure sensors play a crucial role in managing water flow and levels in various industrial applications. These sensors can be analog or digital, with some even offering wireless capabilities for easier integration.

They help monitor water levels, control pumps, and measure the depth, differential, and gauge pressure in high-pressure systems.

Whether you’re dealing with water flow control or high-pressure environments, selecting the right water pressure sensor is essential for maintaining efficiency and ensuring the proper functioning of your system.

Understanding Water Pressure

What is Water Pressure

Water pressure is the force exerted by water on a given area due to its weight and gravity. This force is measured in units like pounds per square inch (psi) or pascals (Pa). Pressure increases with depth in a fluid, such as water, because the weight of the fluid above a certain point adds to the force exerted on that point.

How Pressure Relates to Water Depth and Flow

Water pressure is directly proportional to the depth of the water column, following the hydrostatic pressure equation:

P = ρgh.

Where P is the pressure, ρ is the density of water, g is the acceleration due to gravity, and h is the height of the water column.

As water flows through a pipe or conduit, its pressure will change due to factors like friction, changes in elevation, and the presence of obstacles or bends.

Static vs. Dynamic Water Pressure

Static water pressure refers to the pressure exerted by water when it is at rest, such as the pressure at the bottom of a water tank. It is solely dependent on the height of the water column above the point of measurement. Dynamic water pressure, on the other hand, is the pressure exerted by water when it is in motion, such as flowing through a pipe. This pressure is influenced by factors like the water’s velocity, pipe diameter, and the presence of any obstacles or bends in the system.

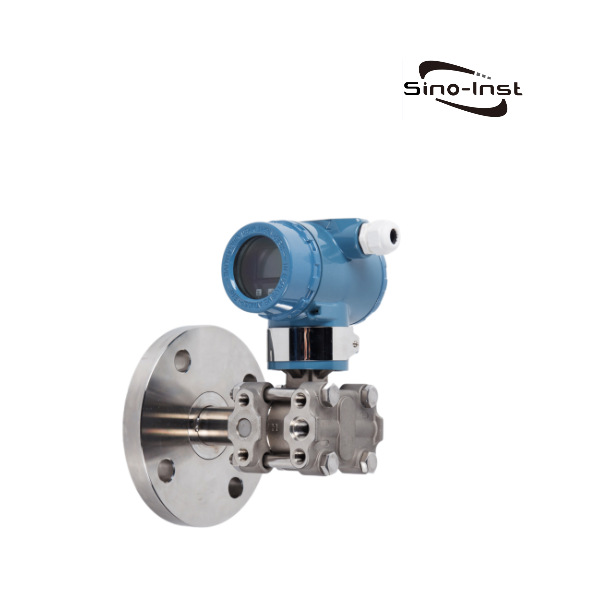

Featured Water Pressure Sensors

Types of Water Pressure Sensors

Selection Guide for Industrial Water Pressure Sensors

Step 1: Identify Requirements

- Choose pressure type: gauge, absolute, differential, or sealed gauge.

- Determine required pressure range.

- Consider environmental factors: temperature, humidity, chemical compatibility, hazardous areas.

Step 2: Pick Sensor Technology

- Weigh pros and cons of sensor technologies: strain gauge, piezoresistive, capacitive, optical.

- Match technology with accuracy, sensitivity, and environmental needs.

Step 3: Check Sensor Performance

- Ensure sensor accuracy and resolution fit your demands.

- Examine response time and long-term stability.

Step 4: Choose Output and Connectivity

- Select output signal: voltage, current, or digital.

- Decide if wireless connectivity is needed or useful.

Step 5: Pick Mounting and Materials

- Select mounting option: threaded, flange, diaphragm seal.

- Check sensor materials compatibility with fluid and environment.

Step 6: Compare Features and Budget

- Review additional features: built-in displays, hazardous area certifications.

- Analyze cost vs. performance, reliability, and features.

Step 7: Research Brands

- Investigate reputable brands: Honeywell, Siemens, Endress+Hauser, Sino-Inst.

- Read reviews and testimonials for product quality and reliability.

- Following these steps will help you select the right industrial water pressure sensor for optimal performance, reliability, and efficiency.

Following these steps will help you select the right industrial water pressure sensor for optimal performance, reliability, and efficiency.

Frequently

Asked

Questions

How to calibrate a pressure transmitter? How often?

10 Point Guide! Selection of Pressure Transmitters

In conclusion, selecting the appropriate water pressure sensor is crucial for optimal system performance and reliability. From gauge, absolute, differential, to sealed gauge pressure sensors, each type offers unique advantages suited for specific applications.

By following the selection guide and considering factors such as sensor technology, performance specifications, output signal, and mounting options, you can make an informed decision.

As a professional manufacturer of pressure transmitters, Sino-Inst offers a wide range of water pressure sensors with years of experience in the industry.

Explore our diverse product offerings and contact our experts for advice on selecting the best sensor for your application. Trust Sino-Inst for dependable and efficient water pressure sensor solutions.

-1.jpg)