Calibrate a pressure transmitter is an important step in ensuring its accurate and reliable measurements. It is normal for the pressure transmitter to have a certain error. But if the error is too large, it needs to be calibrated. There are two types of calibration for pressure transmitters: conventional method and intelligent calibration. No matter what it is, you must make preparations before calibration. And then perform calibration and debugging through the handheld operator. Let’s take a look at how to calibrate the pressure transmitter.

How to Calibrate a Pressure Transmitter

The pressure transmitter has been used for a long time, and there will be certain errors. It needs to be calibrated in time. The common pressure transmitters on the market mainly include conventional pressure transmitters and intelligent pressure transmitters. Two kinds of pressure transmitters The calibration method is different:

Preparations before calibration

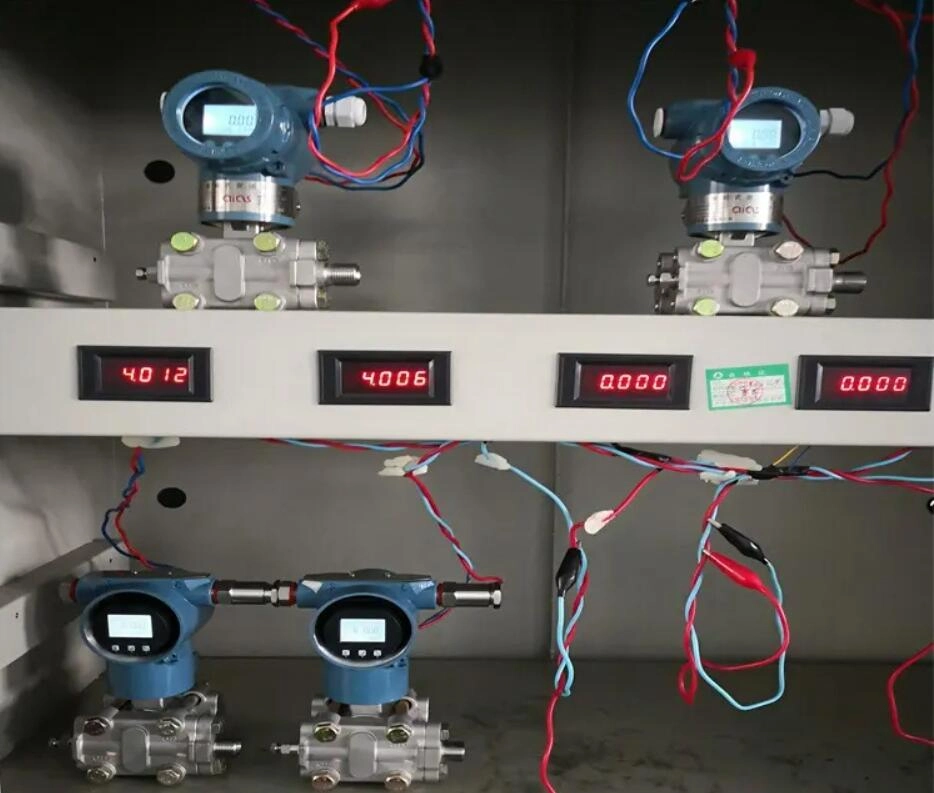

No matter what kind of pressure transmitter it is, preparations must be made before calibration. Including: the pressure source is connected to the self-made joint through a rubber tube. Close the balance valve. And check the sealing of the air circuit. Then put the ammeter (voltmeter), The hand-held communicator is connected to the output circuit of the transmitter, and the calibration starts after power-on and preheating.

Calibration operation

(1) Calibration of conventional pressure transmitters

First adjust the damping to zero state, first adjust the zero point, then fill up the full pressure and adjust the full range, so that the output is 20 mA. The on-site adjustment is fast, and here is the quick adjustment method of zero point and range.

There is almost no effect on the full scale when adjusting the zero point. But it has an impact on the zero point when adjusting the full scale. Its influence is about 1/5 of the range adjustment amount without migration. That is, if the range is adjusted up by 1 mA, the zero point will move up by about 0.2mA. And vice versa.

(2) Calibration of intelligent pressure transmitter

- First do a 4-20 mA fine-tuning. It is used to correct the D/A converter inside the transmitter. Since it does not involve sensing components, no external pressure signal source is required.

- Do another full-scale fine-tuning. Make the 4-20 mA, digital readings match the actual pressure signal applied. Therefore, a pressure signal source is required.

- Finally, do the re-range. Adjust the analog output 4-20 mA to match the external pressure signal source. Its function is exactly the same as that of the zero-adjustment (Z) and range-adjustment (R) switches on the transmitter shell.

How Often to Calibrate a Pressure Transmitter

In order to prevent large errors, the use of pressure transmitters requires regular calibration. So how often is it better to calibrate the pressure transmitter?

Generally speaking, there is no mandatory regulation on the calibration cycle of pressure transmitters. Generally, the company formulates its own calibration cycle standards. It is usually recommended to calibrate once a year. If there are obvious errors or are more important, the calibration cycle can be shortened .

Featured 4-20mA Pressure Transmitters

More Pressure Measurement Solutions

10 Point Guide! Selection of Pressure Transmitters

High-Pressure Flow Meters

Calibrate a pressure transmitter is a crucial step in ensuring accurate and reliable measurement of pressure in various industrial applications. This process involves adjusting and verifying the output of the transmitter against a known pressure value to ensure it is measuring accurately.

Regular calibration is important as it helps to identify any drift or errors in the measurement and ensures the transmitter is operating within its specified tolerance. Inaccurate pressure measurement can result in incorrect process control, which can lead to decreased efficiency and production as well as safety hazards. Hence, the importance of pressure transmitter calibration cannot be overemphasized.

Sino-Inst is a highly reputable manufacturer of pressure transmitters, known for producing high-quality products that deliver accurate and reliable results.

If you need to purchase a pressure transmitter, or you have any questions about calibrate a pressure transmitter. Please feel free to contact our engineers.

-1.jpg)