Differential Pressure Transmitter is a high-precision intelligent on-site differential pressure detection instrument. It is used to measure the parameters of differential pressure, pressure and liquid level of various media in the state of liquid, gas and steam. And convert the measured differential pressure parameters into 4-20mA standard electrical signal output. At the same time, it adopts the HART protocol and has the function of communicating with the handheld device or the host computer. The transmitter has output parameter configuration function, which can meet the needs of different users. It can accurately measure differential pressure, liquid level, vacuum and specific gravity.

Features of SI-3151DP Differential Pressure Transmitter

- Complete measuring range: 0-0.15kPa~42MPa.

- The structure is compact, strong and anti-vibration. Integrated junction box. Local zero and span adjustment. LCD display configuration buttons. Simplify installation, calibration and operation.

- Non-contact local zero point, range adjustment and LCD liquid crystal display parameter configuration buttons are designed on the transmitter housing.

- It adopts solid, plug-in printed circuit board and modular structure. It is helpful for troubleshooting.

- The damping is adjustable, which improves the user’s selectivity.

- Intelligent circuit, user-friendly operation.

- It has independent anti-electromagnetic interference circuit and software anti-interference design.

- It has a sensor for measuring temperature parameters inside. It improves the compensation performance of the transmitter’s ambient temperature.

- Can be displayed directly: measured pressure value. Output analog current value. The measured pressure corresponds to the percentage value of the set range. The temperature value of the sensor body and the medium it is in contact with.

- The transmitter improves the fault recovery capability. It greatly reduces the maintenance workload of the transmitter.

- The LCD liquid crystal display meter works in a multi-parameter cycle display mode.

- With HART protocol remote communication function.

- The innovative design of the δ chamber structure with a fully metal-sealed differential capacitance pressure sensor has achieved significant improvement and good stability in differential pressure (pressure) and temperature measurement.

SI-3151DP Differential Pressure Transmitter – Capacitive Specifications

| Item | Specification |

| Measuring range: | 0~0.1kPa to 0~41MPa |

| Output signal: | 4~20mADC (specially for four-wire 220V power supply, 0~10mADC output), Support 0-5V, 0-10V customization |

| Power supply: | 12~45V DC, generally 24V DC (see the load characteristics in the figure) |

| Load characteristics: | related to the power supply, the load capacity at a certain power supply voltage is shown in the figure (load characteristics), the load impedance RL and the power supply voltage V. The relationship is: RL≤50 (Vs-12) |

| Local Display | pointer type linear indication 0 ~ 100% equal division scale or LCD liquid crystal type, LED digital tube display. |

| Explosion-proof: | a. Flameproof type dIIBT4; b. Intrinsically safe iaIICT6 |

| Temperature range: | Amplifier operating temperature range: -29 ~ +93°C (LT type: -25-+70°C) |

| Measuring element filled with silicone oil: | -40~ +104°C |

| When the flange transmitter is filled with high temperature silicone oil: | -20~ +315°C, ordinary silicone oil: -40~ +149°C |

| Static pressure: | 1, 4, 10.25, 32Mpa |

| Humidity: | Relative humidity is 0 ~ 100% |

| Accuracy: | +0.25%, +0.5%, ±0.1% (intelligent) |

| Stability: | the excellent value of the basic error within six months does not exceed the maximum range |

| Vibration effect: | on any axis, when the vibration frequency is 200Hz, the error is +0.05%/g of the upper limit of the measurement range |

| Power supply influence: | less than 0.005%V of the output range |

| Isolating Diaphragm: | 316 Stainless Steel, Hastelloy C-276, Monel or Tantalum |

| Vent/Drain Valve: | 316 Stainless Steel, Hastelloy C, Monel |

| Flanges and Fittings: | 316 Stainless Steel, Hastelloy C or Monel |

| Contact medium “O” ring: | nitrile rubber, fluorine rubber |

| Filling fluid: | silicone oil or inert oil |

| Bolt: | 316L stainless steel |

| Electronic housing material: | low copper aluminum alloy |

| Pressure introduction connector: | flange, NPT1/4, center distance 54mm; joint NPT1/2 or M20X1.5 male thread spherical cone seal, center distance 50.8.54. T12716-91) Signal wire connection hole: G 1/2” |

| Weight: | 2.4kg |

Order Guide

| Model | Transmitter type | |||||

| SI-1303DP | Pressure transmitter | |||||

| SI-1303HP | Absolute pressure transmitter | |||||

| Code | Scale range | |||||

| 2 | 0-0.10~3.5kPa(0-10~350mmH2O) | |||||

| 3 | 0-0.8~8.0kPa(0-80~800mmH2O) | |||||

| 4 | 0-4.0~40kPa(0-400~4000mmH2O) | |||||

| 5 | 0-20~200kPa(0-2000~20000mmH2O) | |||||

| 6 | 0-70~700kPa(0-0.7~7kgf/cm2) | |||||

| 7 | 0-210~2100kPa(0-2.1~21kgf/cm2) | |||||

| 8 | 0-700~7000kPa(0-7.0~70kgf/cm2) | |||||

| 9 | 0-2.1~21MPa(0-21~210kgf/cm2) | |||||

| 0 | 0-4.1~41MPa(0-41~4100kgf/cm2) | |||||

| Code | Output form | |||||

| E | Linear output 4-20mAdc | |||||

| SF | Linear/square root output 4-20mAdc +HART signal,,Full function buttons on site | |||||

| F | MODBUS-485 signal | |||||

| Code | Structural materials | |||||

| Flange connector | Exhaust/Drain valve | Isolation diaphragm | Filling liquid | |||

| 22 | 316 Stainless steel | 316 Stainless steel | 316 Stainless steel | Silicone oil | ||

| 23 | 316 Stainless steel | 316 Stainless steel | Hastelloy C | Silicone oil | ||

| 24 | 316 Stainless steel | 316 Stainless steel | Monel | Silicone oil | ||

| 25 | 316 Stainless steel | 316 Stainless steel | Tantalum | Silicone oil | ||

| 33 | Hastelloy C | Hastelloy C | Hastelloy C | Silicone oil | ||

| 35 | Hastelloy C | Hastelloy C | Tantalum | Silicone oil | ||

| 44 | Monel | Monel | Monel | Silicone oil | ||

| Code | Shell material | Conduit inlet dimensions | ||||

| A | Low copper aluminum alloy polyurethane coating | M20×1.5 | ||||

| B | Low copper aluminum alloy polyurethane coating | 1/2-14 NPT | ||||

| C | Stainless steel | M20×1.5 | ||||

| D | Stainless steel | 1/2-14 NPT | ||||

| Code | Pressure connection | |||||

| L1 | 1/4NPT-18 Internal thread(excluding waist joint standard) | |||||

| L2 | 1/2NPT-14 Internal thread | |||||

| L3 | M20×1.5 External thread | |||||

| Code | Optional parts | |||||

| M4 | LCD multi – power digital display head | |||||

| B1 | Pipe bending bracket | |||||

| B2 | Plate bending bracket | |||||

| B3 | Pipe mounting bracket | |||||

| C02 | M20×1.5 nut and Φ 14 pressure short tube | |||||

| C12 | 1/2NPT-14 external thread and Φ14 pressure short tube | |||||

| C22 | 1/4NPT-18 external thread and Φ14 pressure short tube | |||||

| C32 | 1/4NPT-18 to M20×1.5 external thread | |||||

| C42 | 1/2NPT-14 to M20×1.5 external thread | |||||

| C43 | 1/2NPT-14 to 1/4NPT-18 internal thread | |||||

| C44 | 1/2NPT-14 to 1/2NPT-14 external thread | |||||

| C45 | 1/2NPT-14 to G1/2 external thread | |||||

| D1 | The side discharge valve is on the upper part | |||||

| D2 | The side discharge valve is on the upper part | |||||

| X1 | Oil ban | |||||

| Da | Flameproof ExdIIBT5Gb;(explosion-proof certificate no. : CE16.1163) | |||||

| Fa | Intrinsically safe ExiaIICT4/T5/T6Ga | |||||

Learn more about differential pressure transmitters

If you cannot find an answer to your question in our Differential Pressure Transmitter, you can always contact us and we will be with you shortly.

More Featured Industrial Pressure Transmitters

How to calibrate a pressure transmitter? How often?

10 Point Guide! Selection of Pressure Transmitters

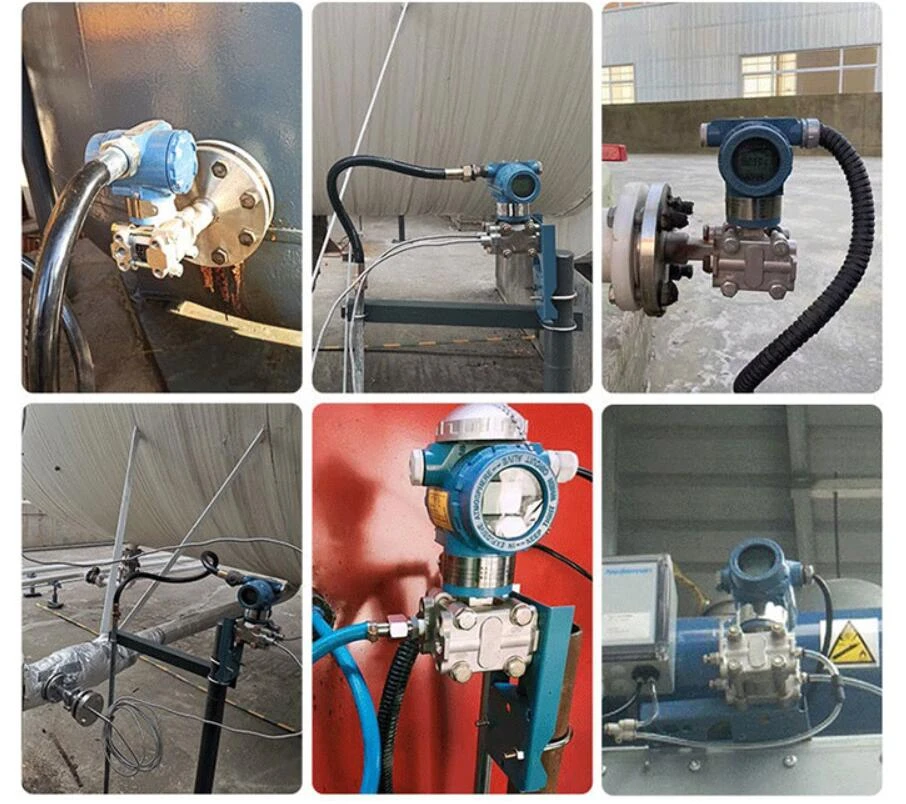

Differential pressure transmitter is a very common type of thermal measuring instrument in the field of industrial production. It is mainly used to measure physical parameters such as pressure, liquid level and flow of liquid medium.

At present, in industrial automation production equipment, the application range of differential pressure transmitter is more and more extensive.

Sino-Inst is a manufacturer of differential pressure transmitters. We supply differential pressure transmitters for a long time, and the price is advantageous.

If you need to configure a differential pressure transmitter, or if you have any questions about the technology of the differential pressure transmitter, please feel free to contact our sales engineers.

Capacitive Differential Pressure Transmitter Manufacturer | Sino-Inst

Differential Pressure Transmitter is a high-precision intelligent on-site differential pressure detection instrument. It is used to measure the parameters of differential pressure, pressure and liquid level of various media in the state of liquid, gas and steam. And convert the measured differential pressure parameters into 4-20mA standard electrical signal output. At the same time, it adopts the HART protocol and has the function of communicating with the handheld device or the host computer. The transmitter has output parameter configuration function, which can meet the needs of different users. It can accurately measure differential pressure, liquid level, vacuum and specific gravity.

Product SKU: SI-3151DP Differential Pressure Transmitter - Capacitive

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 225.00

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)