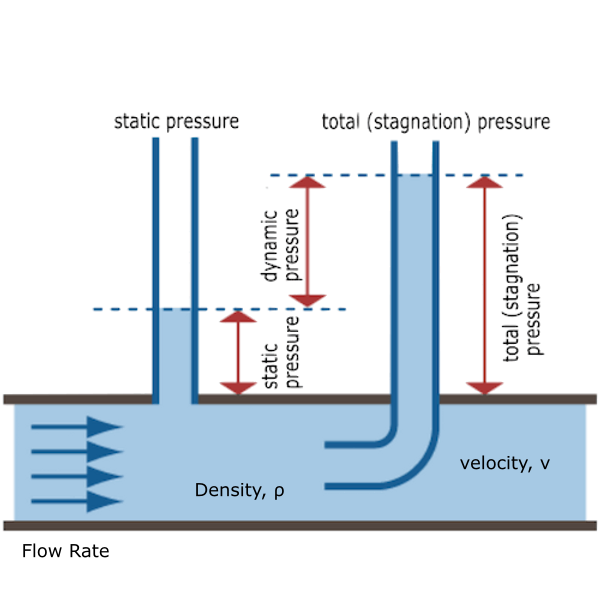

Whether it is a gas or a liquid, we can call it a fluid. There is bound to be pressure in fluids. Of course, these pressures are not exactly the same. What we most often discuss are static pressure, dynamic pressure and total pressure. Simply summarize the relationship between them: A stationary fluid has static pressure; any fluid with velocity or flowing fluid has dynamic pressure; the total pressure represents the sum of the static pressure and dynamic pressure of the fluid flow; total pressure = static pressure Pressure + dynamic pressure.

Sino-Inst is a manufacturer of flow meters and pressure transmitters. Therefore, we provide users with various pressure and flow measurement solutions all year round. We know that there is a relationship between fluid pressure and flow. Then understanding the pressure of the fluid is an essential prerequisite.

What is Static Pressure?

Simply put, a stationary fluid has static pressure. When the fluid is in a stationary position, that is, when there is no flow or constant flow, only static pressure acts uniformly on the fluid.

Static Pressure=pgh

In fact, static pressure can be thought of as the pressure exerted by a fluid on a solid surface. Examples include the walls of a pipe or the surface of an object immersed in a fluid. It is an important parameter in various fields, including engineering, aerodynamics and HVAC (heating, ventilation and air conditioning) systems.

Static pressure measurement

Static pressure parameters are essential measurements for many industrial processes. Below I will introduce in detail the application of static pressure in industrial measurement.

Static Pressure Sensor

When measuring static pressure, it is crucial to use the correct static pressure sensor.

Static pressure sensors need to be able to accurately measure small pressure changes and work stably under various environmental conditions.

In environments with high temperature, high pressure or corrosive media, it is even more important to choose the appropriate sensor and installation method.

What is Dynamic Pressure?

Dynamic pressure represents the pressure exerted by a fluid due to its motion or velocity. A flowing fluid has dynamic pressure. It is directly related to the velocity of the fluid.

The relationship between dynamic pressure and fluid velocity

Dynamic pressure is the pressure generated when a fluid moves, and it is directly related to the speed of the fluid.

According to Bernoulli’s equation, the total energy of a fluid consists of its static pressure, dynamic pressure and potential energy (which can be ignored when the fluid flow height is constant).

Dynamic pressure can be expressed by the following formula:

Dynamic pressure = ρ/2 ⋅ v2

in:

ρ is the density of the fluid,

v is the velocity of the fluid.

This relationship shows that the dynamic pressure of a fluid is proportional to the square of its velocity. Therefore, by measuring the dynamic pressure of a fluid, we can deduce the velocity of the fluid, which is crucial in flow calculations and flow rate monitoring.

Dynamic pressure measurement

Dynamic pressure is usually measured using a pitot tube, which is a simple instrument with an opening facing the flow. A pitot tube measures both the total pressure and the static pressure of a fluid, with the dynamic pressure calculated from the difference between the two. For accurate measurement of lower velocity fluids, a pitot-static tube with an amplifier is sometimes used.

In addition to pitot tubes, there are other techniques used for dynamic pressure measurement, such as:

- Differential pressure flow meter: The flow rate is estimated by measuring the pressure difference before and after the fluid passes through the constriction or throttling device.

- Hot-wire anemometer: Uses the heat-carrying effect of the fluid to estimate the dynamic pressure and then calculate the flow rate.

- Laser Doppler flow meter: Uses the laser Doppler effect to measure the velocity of particles in a fluid to derive dynamic pressure.

Dynamic Pressure Sensor

A pressure sensor specifically designed to measure dynamic pressure in fluid flow can be called a dynamic pressure sensor.

Dynamic pressure sensors utilize various sensing technologies to convert pressure into electrical signals that can be measured and analyzed. Some common types of dynamic pressure sensors include piezoelectric, piezoresistive, and capacitive sensors.

However, we actually also have a professional dynamic pressure sensor, also called High Frequency dynamic Pressure Sensor. The natural frequency of the sensor can reach 1-2MHz, and it can measure high-frequency pressure changes in the bandwidth range of 0-200KHz. The pressure range is -100KPa~0~10Kpa…100MPa. The preferred solution for dynamic pressure measurement.

What is Total Pressure?

Total pressure refers to the sum of static pressure and dynamic pressure of a fluid at a certain point. It represents the total energy of the fluid at a certain point in the state of motion. In fluid mechanics, according to Bernoulli’s equation, the total pressure of the fluid in a closed pipe is conserved when there is no external force acting and the fluid is an incompressible fluid.

Total pressure = static pressure + dynamic pressure

Dynamic pressure = ρ/2 ⋅ v2

in:

ρ is the density of the fluid,

v is the velocity of the fluid.

In practical applications, we can measure the total pressure using a pitot tube, which can simultaneously measure the total pressure of a flowing fluid and the surrounding static pressure. The dynamic pressure can then be obtained by subtracting the static pressure from the total pressure.

Difference Between Static Pressure, Dynamic Pressure And Total Pressure

After understanding the detailed explanations of the above departments, it is not difficult for us to know the differences between the three. simply put:

- Static pressure is the pressure exerted by a fluid when it is at rest. It is measured perpendicular to the fluid surface and is independent of the direction of flow.

- Dynamic pressure is the pressure exerted by fluid movement. It is measured parallel to the direction of flow and depends on the velocity of the fluid.

- Total pressure, also called stagnation pressure, is the sum of static pressure and dynamic pressure.

Example

Suppose we have a pipe in an industrial piping system and we want to measure the flow rate of water through this pipe. The water in the pipe is an incompressible fluid, and we assume that the flow is stable. We placed a pressure measuring device at a typical cross-section in the pipeline, which can measure both static pressure and total pressure simultaneously.

Now we have the following data:

Measured static pressure P static = 50 kPa (kilopascals)

Measured total pressure Ptotal = 60 kPa

Density of water ρ = 1000 kg/m³ (kilogram per cubic meter)

Now we need to calculate the velocity v of the water.

According to Bernoulli’s equation, the total pressure is the sum of static pressure and dynamic pressure. We first need to calculate the dynamic pressure P dynamic.

From Bernoulli’s equation:

Ptotal = Pstatic + 1⁄2 ρ v²

We can use this equation to solve for the flow velocity v.

P dynamic = P total – P static

P = 60 kPa – 50 kPa

P = 10 kPa

Converting to standard units we have 10 kPa = 10000 Pa (Pascal).

Then, put the dynamic pressure expression into the solution velocity:

v² = 2 × 10000 Pa⁄1000 kg/m³

v² = 20000⁄1000

v² = 20 m²/s²

v = √20m/s

v ≈ 4.47 m/s

Therefore, the flow rate of water through this pipe is approximately 4.47 meters per second.

This example shows how to apply Bernoulli’s equation to measure and calculate static pressure, dynamic pressure, and total pressure using real data. In industrial applications, such measurements and calculations are critical for pipeline design, fluid transfer, and monitoring of industrial systems.

More About Measurement of fluid pressure and flow

Steam Pressure Sensor/transducer for Industrial Steam Measurement

What Is Solvent Flow Meter? Industrial Selection Guide

What Is a BTU Meter? | BTU Energy Measurement Systems

Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Gauge Pressure vs Absolute Pressure | Differences and Relationships

How to calibrate a pressure transmitter? How often?

Understand the concepts of static pressure, dynamic pressure and total pressure, and how to use Bernoulli’s equation to perform actual flow rate calculations. This not only helps engineers make more accurate design and maintenance decisions, but also ensures efficient and safe system operation.

Of course, there is much more to industrial measurement than this. For example, crude oil flow measurement is a key link in the petrochemical industry, and our flow meter products can provide accurate flow data to ensure the smooth progress of the process.

As an experienced manufacturer, Sino-Inst is proud to offer a range of reliable and accurate industrial measurement and control instruments. We understand the specific needs of different industries and applications and can provide customized services to ensure your needs are fully met.

Choose Sino-Inst, choose a trustworthy partner, we will provide customized support and services for your measurement needs. Consult now and let us help you achieve more precise industrial measurement and control.

-1.jpg)