Solvent Flow Meter: a term that might sound complex, but it’s a crucial tool for many industries. In this guide, we’ll break down what this device is and why it’s so important. From the foods we eat to the cars we drive, solvent flow meters play a behind-the-scenes role in ensuring quality and efficiency. Dive in to learn about this unsung hero of the industrial world.

What is solvent flow meter?

A solvent flow meter is an intricate instrument specifically designed to monitor the volume or mass flow rate of solvents. In the realm of industrial operations, ensuring precise measurements of solvent amounts is paramount. Depending on their chemical makeup, solvents can be categorized into two main types: organic and inorganic. These solvents hold pivotal roles, serving as fundamental materials in diverse sectors, notably including the manufacturing of coatings, paints, and dyes.

Opting for the right flow meter in chemical applications is a nuanced endeavor. It’s imperative to have a comprehensive understanding of the solvent’s properties and the conditions under which it operates. Factors such as temperature and line pressure wield significant influence. Solvents can be tricky – some are thick, some are thin, and they can be used in many different industries. Thus, the more detailed the data you provide about the solvent and the operating conditions, the more adeptly we can guide you towards the ideal flow meter tailored to your unique needs.

Basics of chemical solvent

Solvents are substances that can dissolve other solids, liquids, gases and other solutes. The most common solvent in our daily life is water. Generally solvents have low boiling points, are volatile and cannot react chemically with solutes. Solvents are usually colorless and transparent liquids with a distinctive odor.

Solvents play a very important role in adhesives.

Organic solvents are a large group of organic compounds that are widely used in life and production. They have a small molecular weight and are liquid at room temperature. Organic solvents include a variety of substances such as paraffins, olefins, alcohols, aldehydes, amines, esters, ethers, ketones, aromatic hydrocarbons, hydrogenated hydrocarbons, terpenes, halogenated hydrocarbons, heterocyclic compounds, nitrogen-containing compounds, sulfur-containing compounds, etc. Compounds, etc. Most of them are toxic to humans.

Solvents are usually found in paints, adhesives, varnishes and cleaners. Commonly used organic solvents are DMF, cyclohexanone, acetonitrile, acetic acid, methyl acetate, ethyl acetate, isopropyl alcohol, vinyl acetate, cyclohexane, n-hexane, n-heptane, etc.

Organic solvents are a class of organic compounds that can dissolve some substances insoluble in water (such as grease, wax, resin, rubber, dye, etc.). It is characterized by its liquid state at room temperature and pressure. It has greater volatility. During the dissolution process, the properties of solute and solvent remain unchanged.

There are many types of organic solvents, which can be divided into 10 major categories according to their chemical structure.

- Aromatic hydrocarbons: benzene, toluene, xylene, etc.

- Aliphatic hydrocarbons: pentane, hexane, octane, etc.

- Alicyclic hydrocarbons: cyclohexane, cyclohexanone, toluene cyclohexanone, etc.

- Halogenated hydrocarbons: chlorobenzene, dichlorobenzene, dichloromethane, etc.

- Alcohols: methanol, ethanol, isopropanol, etc.

- Ethers: ethyl ether, propylene oxide, etc.

- Esters: methyl acetate, ethyl acetate, propyl acetate, etc.

- Ketones: acetone, methyl butanone, methyl isobutyl ketone, etc.

- Diol derivatives: ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, etc.

- Other: acetonitrile, pyridine, phenol, etc.

Types of Solvent Flow Meters

Solvent flow meters come in various types, each with its own unique design and way of working. Let’s break down the most common ones to help you understand them better:

Turbine Flow Meters

In the past, the best approach for this type of fluid was to use a turbine flow meter. The turbine rotor is suspended by ball or sleeve bearings and has virtually no drag coefficient. This allows turbine flow meters to be used with low viscosity and non-lubricating fluids.

- Simple, durable design

- Easy installation and maintenance

- Reliable operation under a wide range of temperatures and pressures

- Turndown ratio is up to 35:1

- Good level of accuracy at an economic price

- Wide variety of process connections

- Low pressure drop

Oval Gear Flow Meters

Another option is the oval gear flowmeter (PD flowmeter), which is a positive displacement device using dual oval rotors. Rotors inherently provide a better seal because their gear design captures a small portion of the fluid at the capillary sealing point, preventing leakage around the measurement element.

- The viscosity can reach up to 1000-2000mPa.s

- The temperature resistance level can reach up to -10~450℃; (thermal insulation jacket type);

- Special flow meters can be customized according to customer requirements;

- The electronic meter can provide 4-20MA output, pulse output, 485 read-through protocol, and HART protocol.

- The measurement accuracy of oval gear flowmeter is high, the basic error is generally ±0.5%R, and special ones can reach ±0.2%R or higher. Particularly suitable for use in sites requiring high-precision measurements.

- Measuring the rotational flow and flow velocity field distortion of the pipe obstruction has no impact on the measurement accuracy, and there are no requirements for the front straight pipe section.

- Oval gear flowmeter can be used to measure high viscosity fluids with a wide flow range, generally 10:1 to 5:1, and special ones up to 30:1 or greater.

- It has direct reading of on-site flow rate and can measure the cumulative total without external power supply. The display is clear and easy to operate.

Magnetic Flow Meters

Electromagnetic flow meters are also available, both of which enable highly accurate and efficient solvent flow measurements.

- Measurement not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

- No obstructing flow parts in the measuring tube. No pressure loss, and the requirements for straight pipe sections are low. Unique adaptability to slurry measurement;

- Reasonable selection of sensor lining and electrode material. So magmeter has good corrosion resistance and wear resistance;

- The converter uses a novel excitation method, low power consumption, stable zero point and high accuracy. Flow range can reach 150: 1;

- The converter can be integrated or separated with the sensor;

- The flow meter is a two-way measurement system. With three totalizers built in: forward total, reverse total, and difference total. It can display positive and reverse flow and has multiple outputs: current, pulse, digital communication , HART;

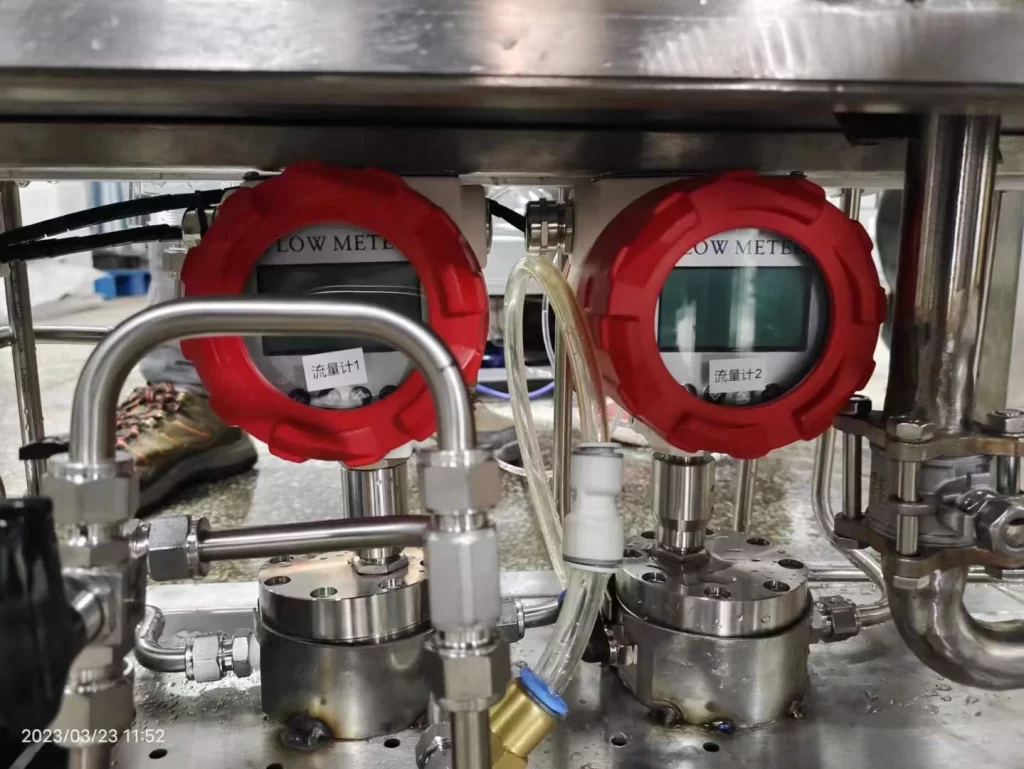

GF Series Gear Flow Meter

Now, our new product, the circular gear flow meter, is also becoming an important Solvent Flow Meter.

Portable Doppler Ultrasonic Flow Meter-More Powerful

The Portable Doppler Ultrasonic Flow Meter’s sensor is highly sensitive and can measure liquids with low particle and bubble content. It is a flow measurement instrument with more powerful functions.

- Both dirty and pure liquids can be measured. It is equivalent to a high-precision Doppler ultrasonic flow meter and a high-precision time-difference ultrasonic flow meter.

- Non-contact flow meter, external clamp-on installation, no need to stop flow or cut off pipelines.

- Can resist frequency converter interference.

- It is very easy to solve application problems that cannot be solved by other ultrasonic flowmeters such as oversized pipe diameters, thick pipe walls, and cement linings.

- Built-in data recording function, can record 10 files and 65072 data points.

- With data playback function, the flow meter is equipped with special software with Microsoft Windows style graphical interface. Through the RS-232 interface, the data can be downloaded to the computer for comprehensive analysis of the data. The instantaneous flow-time curve waveform can be displayed visually and can be arbitrarily zoomed along the time axis, providing a powerful tool for managers to analyze data.

- Built-in flow meter calibration function provides fast and convenient operation.

- It has the function of annual, monthly and daily traffic accumulation. It can record the accumulated traffic of the previous 5 years and this year, the previous 12 months and this month, the previous 31 days and today.

More Featured Products

Selection Guide for Industrial Solvent Flow Meters

Selecting the right solvent flow meter is crucial for precise measurements. Here are some vital factors to keep in mind when making your choice:

- Material Compatibility:

- Why It Matters: Not all flow meters can handle every solvent type. The material of the flow meter should resist the solvent to prevent corrosion or damage.

- Tip: Check the solvent’s chemical properties and choose a flow meter made of compatible materials.

- Flow Rate:

- Why It Matters: Every flow meter has a range where it works best. If the solvent’s flow is too fast or slow, the meter might not read it accurately.

- Tip: Know your expected flow rates and match them with a meter designed for that range.

- Accuracy:

- Why It Matters: For precise operations, you need a flow meter that can provide accurate readings. Some meters are more precise than others.

- Tip: Look at the meter’s accuracy rating, often given as a percentage. The closer to 100%, the better.

- Installation and Maintenance:

- Why It Matters: Some flow meters are easy to install and require little upkeep, while others might need regular checks and calibrations.

- Tip: Think about how much time and effort you can invest in installation and maintenance.

- Operating Environment:

- Why It Matters: Factors like temperature, pressure, and humidity can affect how a flow meter works.

- Tip: Ensure the flow meter you pick can handle the conditions where you plan to use it.

- Cost:

- Why It Matters: While you shouldn’t cut corners, you also need to stay within your budget.

- Tip: Consider both the initial cost and potential long-term expenses, like maintenance or replacement parts.

Selecting the perfect solvent flow meter is an investment in your operations’ accuracy and efficiency. By considering these factors, you’ll be well on your way to making an informed decision.

Applications of Solvent Flow Meters in Different Industries

Solvent flow meters play a pivotal role in various sectors. Let’s dive into some of the industries where these devices are indispensable:

Paint and Coatings Industry:

Use: To measure the volume of solvents added to create paints and coatings.

Pharmaceuticals:

Use: To monitor the flow of solvents used in drug production and extraction processes.

Petrochemicals:

Use: For tracking the flow of various solvents in processes like oil refining.

Adhesive Manufacturing:

Use: To measure solvents that give adhesives their sticky nature.

Textile Industry:

Use: In dyeing and printing processes where solvents are used.

Cosmetics and Personal Care:

Use: In the production of items like perfumes, where solvents are mixed with fragrances.

Food and Beverage:

Use: In processes that require solvents for flavor extraction or preservation.

Cleaning Products Manufacturing:

Use: To monitor solvents added to products like detergents or surface cleaners.

These industries, among others, rely heavily on solvent flow meters to maintain product quality, safety, and efficiency. As we can see, these devices aren’t just about measuring; they’re about ensuring industries run smoothly and consumers get the best.

More Flow Measurement Solutions

What Is a BTU Meter? | BTU Energy Measurement Systems

Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

Volumetric Flow Meters: Comprehensive Guide and Product List

Choosing the Right Inline Water Flow Meter

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

In the vast realm of industrial processes, solvent flow meters hold a crucial spot. They ensure quality, efficiency, and safety in countless products we use daily. Whether it’s the paint on our walls, the medication in our cabinets, or the fragrance we wear, these devices play an unseen but paramount role.

Choosing the right solvent flow meter, understanding its importance in different industries, and realizing the factors that influence its selection can make a significant difference in the outcome of various production processes. That’s where we step in. At Sino-Inst, our rich experience as manufacturers and suppliers equips us to guide and provide you with the best. Whether you have unique requirements or need expert advice, our doors are always open.

Reach out to us for more information or to discuss your requirements. We value your feedback and look forward to serving your needs. Get in touch with the experts today!

-1.jpg)