Bidirectional Flow Meters can simultaneously measure the flow of liquid or gas in both positive and negative directions. Bidirectional flow, a process in which the conveying and control functions use the same pipeline to facilitate bidirectional flow, is a critical but challenging requirement in certain industries. While unidirectional flow measurement is simple with existing technology, bidirectional flow measurement can present difficulties. Instruments capable of measuring bidirectional flow include electromagnetic flowmeters, mass flowmeters, ultrasonic flowmeters, and porous orifice flowmeters. Sino-Inst offers a variety of solutions for accurate and cost-effective bi-directional flow measurement. The right bi-directional flow meter can greatly improve the operating efficiency of these and other applications.

Bidirectional Flow Measurement

Bidirectional flow measurement is the process of accurately gauging the flow of fluids or gases moving in two opposite directions in a conduit. This type of flow measurement plays an integral role in industries such as oil and gas, water treatment, and aviation, where precise measurement is critical for operational efficiency and profitability.

Technical Challenges in Bidirectional Flow Measurement

Despite its importance, accurate bidirectional flow measurement can present several challenges:

Technology Limitations: Not all flow meter technologies can accurately measure bidirectional flow. Some meters are designed solely for unidirectional flow and may deliver inaccurate readings when applied to bidirectional flow scenarios.

Installation and Calibration: Correct installation and calibration are vital to ensuring accurate bidirectional flow measurements. Incorrect positioning of the meter, improper pipe size selection, or flawed calibration can all lead to significant measurement inaccuracies.

Variable Flow Conditions: Changes in temperature, pressure, or fluid characteristics can impact the measurement accuracy of some flow meters. Therefore, these variables need to be accounted for when selecting and setting up a bidirectional flow meter.

Overcoming these challenges requires careful selection of the appropriate metering technology, proper installation, calibration, and regular maintenance. In this way, reliable and accurate bidirectional flow measurement can be achieved, leading to improved operational efficiency.

Examples of Bidirectional Flow Measurement

Bidirectional flow measurement plays a crucial role in a variety of settings, including:

- Water Treatment Plants: Monitoring the raw water feed directed to multiple facilities, ensuring a balanced and efficient distribution.

- Industrial Plants: Keeping track of bidirectional steam lines that transfer steam from one unit to another within a plant, promoting energy efficiency.

- Power Transmission: Regulating the pumping of dielectric fluid into underground electrical cables, which helps dissipate heat from high-voltage power lines and enhances safety.

- Gas Storage Fields or Reservoirs: Managing the injection or withdrawal of gas, aiding in optimal storage and utilization.

- Plant Operations: Overseeing the purging and blanketing of nitrogen, which helps maintain safe and efficient plant operations.

- Chilled Water Plants: Controlling the flow within decoupling headers, ensuring a smooth and effective operation of the cooling system.

Each of these examples demonstrates the importance of bidirectional flow measurement in maintaining efficient and safe operations across various industries.

Types of Bidirectional Flow Meters

Not all flowmeter technologies are capable of bi-directional flow measurement.

So, which flowmeters can be used as bidirectional flowmeters?

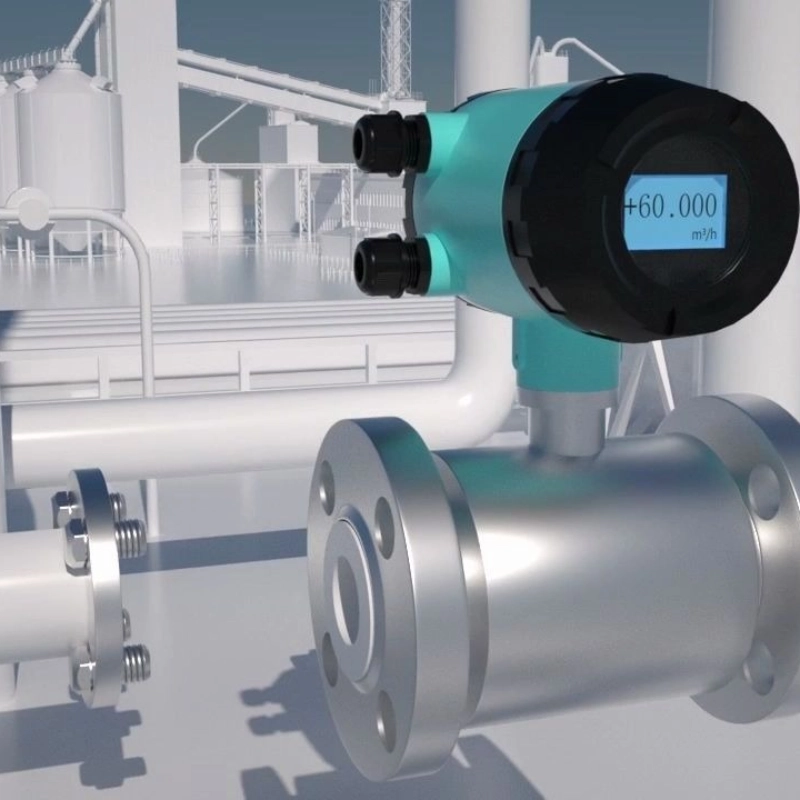

The first options are electromagnetic flowmeters and ultrasonic flowmeters. Because these two flowmeters have no flow resistance inside. Therefore, it is most commonly used in two-way liquid flow measurement.

Of course, there are also mass flow meters and perforated plate flow meters. Electromagnetic flowmeters and ultrasonic flowmeters cannot measure the flow of steam and gas. At this time, mass flow meters or perforated plate flow meters can be considered.

Bidirectional Flow Meters from Sino-Inst Flow Controls

How to Select the Right Bidirectional Flow Meter

How to Select the Right Bidirectional Flow Meter

Choosing the right bidirectional flow meter is crucial to ensuring accurate and reliable flow measurements. Here are some key factors to consider when making your selection:

- Type of Fluid: Different flow meters are designed to handle different types of fluids. For instance, electromagnetic flow meters work best with conductive fluids, while ultrasonic flow meters can measure the flow of virtually any pure liquid or gas.

- Flow Range: Each type of flow meter has its own flow measurement range. Choose a flow meter that covers the flow range.

- Pressure and Temperature: The operating pressure and temperature in your application can impact the performance of a flow meter. For instance, certain materials used in flow meter construction may not stand high temperatures or pressures, so it’s essential to choose a meter that can handle your application’s conditions.

- Accuracy Requirements: Different applications require different levels of accuracy. For instance, a pharmaceutical application might require a very accurate mass flow meter, while a less precise meter may suffice for a water treatment plant.

- Industry-Specific Requirements: Some industries have specific requirements or standards that must be met. For instance, the food and beverage industry might require flow meters that are easy to clean and have specific material requirements.

- Cost and Maintenance: Lastly, consider the initial cost of the meter and the long-term costs associated with maintenance and calibration. It might be worth investing in a higher-priced meter if it offers lower maintenance costs and longer service life.

By considering these factors, you can choose a bidirectional flow meter that fits your specific application and delivers accurate and reliable measurements.

More Flow Measurement Solutions

Volumetric Flow Meters: Comprehensive Guide and Product List

Choosing the Right Inline Water Flow Meter

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

Industrial Inline Flow Meters | Selection List

High-Performance Marine Fuel Flow Meters | Save Your Costs!

Industrial Fuel Flow Meters – Choose the Right one for You

At Sino-Inst, we’ve been leaders in the flow measurement industry for many years, and we’ve built our reputation on our dedication to quality, innovation, and customer service. Our team consists of industry veterans who bring a wealth of experience and expertise to the table, ensuring that we provide our clients with reliable, high-quality bidirectional flow meters that are customized to meet their unique needs.

Our solutions span a variety of industries, from oil and gas, water treatment, and aviation, to power generation, and more. Each product we offer is backed by thorough research, meticulous engineering, and rigorous testing, assuring you of durability, accuracy, and performance. This commitment to excellence, coupled with our extensive industry experience, solidifies our status as trusted experts in flow measurement technology.

Whether you’re looking for a solution for your specific application or need assistance in selecting the right bidirectional flow meter, our team at Sino-Inst is ready to help. We offer customizable solutions tailored to your requirements and a commitment to outstanding service. Reach out to us today and let our experience and expertise guide you to the perfect flow measurement solution for your needs. Your satisfaction is our success.

-1.jpg)