Every drop counts when it comes to fuel. Precise fuel management is a critical need in various industries, be it aviation, marine, automotive, or oil & gas. And, the device at the heart of it all is the fuel flow meter. For those looking for an ideal fuel flow measurement solution, this guide will help you understand the world of fuel flow meters and pick the right one that fits your industrial needs.

What is a Fuel Flow Meter?

A fuel flow meter is an essential device used to measure the volume of fuel consumed in industrial and commercial applications. It provides an accurate count of fuel usage, offering valuable data for monitoring and controlling fuel consumption.

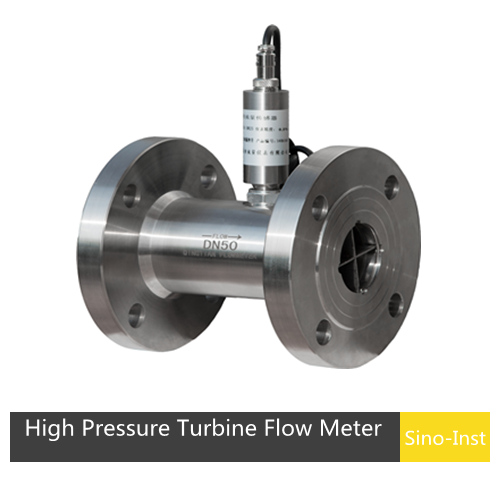

Featured Industrial Fuel Flow Meters

At Sino-Inst, we offer a wide range of fuel flow meters designed to cater to various industrial requirements. Our products offer unique features and are built for durability and precision. Whether it’s high accuracy or robustness you’re seeking, we’ve got you covered.

Why are Fuel Flow Meters Important in Industry?

Fuel flow meters are critical in industries where fuel consumption impacts operational costs and efficiency. Their accurate measurements can help reduce fuel wastage, detect leaks, and monitor engine performance, all of which are crucial in the industrial sector. An example of their impact is reflected in a case study by U.S. Department of Energy, which revealed that using fuel flow meters resulted in a 5% decrease in fuel usage in manufacturing plants.

Different Types of Fuel Flow Meters

Various types of fuel flow meters cater to different requirements and applications. They include:

Positive Displacement Meters: These offer a high level of accuracy, especially at low flow rates, making them suitable for domestic fuel consumption measurement.

Mass Flow Meters: Mass flowmeter is a type of flowmeter with the highest measurement accuracy. It is mostly used for trade measurement. But the cost is also high.

It’s worth noting that each type has its own set of pros and cons, which must be weighed carefully against your unique requirements.

7 Factors to Consider When Choosing a Fuel Flow Meter

Selecting the perfect fuel flow meter for your industrial operations can be quite the task. But don’t fret, we’re here to make the process easier. Here are seven crucial factors to consider:

- Type of Fuel: This might seem obvious, but the kind of fuel you’re dealing with plays a significant role in your choice of meter. Diesel, petrol, kerosene, biodiesel – each fuel type possesses different characteristics that can impact the meter’s performance. For example, certain flow meters are specially designed for corrosive fuels, while others might work better with viscous fuels.

- Flow Rate: The flow rate – the speed at which fuel passes through the meter – is a critical factor. You need a flow meter that can handle your operation’s fuel throughput. For instance, positive displacement meters are typically chosen for lower flow rates, while turbine meters can handle higher rates.

- Accuracy: How accurate do your readings need to be? While some industries require high precision measurements, others might afford some margin of error. According to a report by the National Institute of Standards and Technology, a 1% increase in accuracy can lead to savings of over $500 per year in a typical industrial setting.

- Operating Conditions: Consider the environmental and operating conditions the meter will face. High temperatures, extreme pressures, corrosive environments – all of these can impact the durability and lifespan of the meter. For example, ultrasonic flow meters tend to perform well in harsh operating conditions.

- Installation Requirements: Your choice might be influenced by your installation constraints. Do you have enough space? Can the meter handle the orientation of your pipes? A meter that’s easy to install and configure can save you a lot of headaches down the line.

- Budget: Like all business decisions, budget plays a significant role. When considering the cost, don’t just think about the upfront price of the meter. Also, factor in maintenance costs, potential savings from improved efficiency, and the lifespan of the meter.

- Supplier Reputation: Finally, consider the reputation of the supplier. A good supplier like Sino-Inst not only offers quality products but also provides excellent after-sales service and technical support.

Armed with this knowledge, you’re now one step closer to finding the fuel flow meter that’s just right for you. Remember, making the right choice could mean significant cost savings and improved efficiency for your operations.

Case Study: Customized Heavy Oil Flow Meter for a Coal Fired Steam Power Plant

Meet Andik, a supplier for a coal-fired steam power plant based in Indonesia. He reached out to us with an urgent request for a heavy oil flow meter, with very specific requirements: an 8″ diameter, flange connection, and an estimated flow of around 600 m3/hour.

Understanding the urgency of his situation, we didn’t waste any time. Our team quickly identified a solution that would meet Andik’s needs: our SI-3601-E-DN200-3-B-1-/–/-1-H fuel flow meter. This model is designed with a diameter of 8″ (DN200), a flow range of 68-340 m3/h, and a pressure rating of 20 bar, perfectly suited for Andik’s specifications.

Not only that, but this meter also features an ANSI 150 standard flange connection, an operating temperature range of 50-70 ℃, and intrinsic safety explosion proofing. With an impressive accuracy of 0.2, it ensures precise measurements in the toughest industrial conditions.

The response from Andik was overwhelmingly positive. He reported back that the fuel flow meter was performing excellently in his heavy oil application, meeting all his expectations. This real-world application not only showcases the effectiveness of our fuel flow meter but also Sino-Inst’s ability to deliver fast, customized solutions that meet our customers’ unique needs.

More Flow Measurement Solutions

Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Top Guide to CO2 Flow Meters

Ultrasonic Clamp on Flow Meter for Quick & Easy Measurements

What Is a 4 to 20 Milliamp Signal?

How to Choose the Right Heating Oil Flow Meter for Your Business

Top 3 Flow Meters for Oil

Navigating the world of fuel flow meters can seem daunting, but with the right information, the task becomes more straightforward. Remember, choosing the right meter is about understanding your unique needs and finding a solution that caters to those needs. As an experienced manufacturer and supplier, Sino-Inst can help you customize the perfect fuel flow meter for your industrial application. Don’t hesitate to get in touch with us today!

-1.jpg)