Heating oil flow meters are devices that measure the flow rate of heating oil through a pipeline. Ensuring accurate monitoring and control of fuel consumption. They are essential in various industries. Including manufacturing, energy, and transportation, where heating oil is used as a primary fuel source.

Choosing the right heating oil flow meter for your business can significantly improve your fuel management system, increase efficiency, and reduce operational costs. We will discuss essential factors to consider when selecting a heating oil flow meter and how to find the best solution to meet your specific needs.

Different Types of Heating Oil Flow Meters

There are several types of heating oil flow meters available, each with its advantages and drawbacks. Some of the most common types include:

There are several types of heating oil flow meters available, each with its advantages and drawbacks. Some of the most common types include:

a) Positive Displacement Flow Meters:

These meters measure the flow rate by dividing the oil into small, fixed volumes and counting the number of divisions passing through the meter. They are highly accurate and can handle a wide range of flow rates but may have higher maintenance requirements due to their mechanical nature.

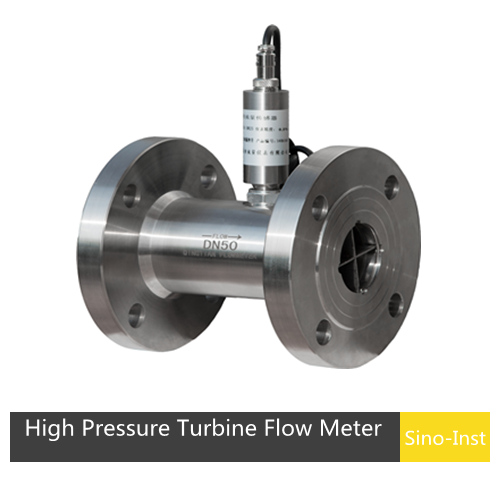

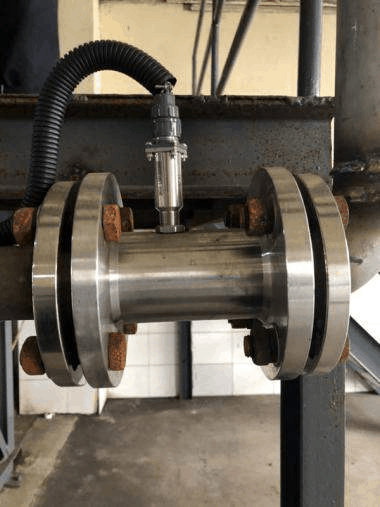

b) Turbine Flow Meters:

Turbine meters measure the flow rate by using a spinning rotor that generates a frequency proportional to the flow velocity. They offer high accuracy and rapid response times but may be sensitive to fluid viscosity changes and require regular calibration.

c) Ultrasonic Flow Meters:

Ultrasonic meters use sound waves to measure the flow rate of heating oil. They are non-invasive, highly accurate, and have low maintenance requirements but can be more expensive than other options.

d) Coriolis Flow Meters:

These meters measure the mass flow rate by detecting the Coriolis effect on a vibrating tube. They are highly accurate and can measure both mass flow and density but may be more expensive and complex to install.

Key Factors to Consider When Choosing a Heating Oil Flow Meter

According to our many years of service experience, To choose the right heating oil flow meter for your business, consider the following factors:

- Accuracy: Consider the level of accuracy required for your specific application. Energy production, may demand higher accuracy levels to ensure optimal performance.

- Flow Rate Range: Select a flow meter that can handle the range of flow rates you expect to encounter in your system.

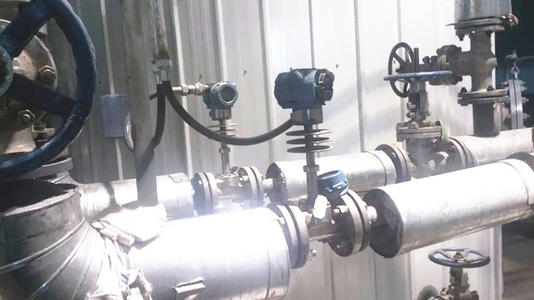

- Pipeline temperature and pressure: Special conditions such as high temperature and high pressure require customized flow meters.

- Installation and Maintenance: Choose a flow meter that is easy to install and maintain to minimize downtime and operational costs.

- Cost: Consider the initial cost, ongoing maintenance costs, and potential cost savings from increased efficiency when selecting a flow meter.

- Operating Conditions: Choose a flow meter that can withstand the temperature, pressure, and environmental conditions of your system.

Industry Applications of Heating Oil Flow Meters

Heating oil flow meters are used across various industries, including:

Energy Production: Heating oil flow meters are used in power plants to monitor and control fuel consumption, ensuring optimal performance and efficiency.

Manufacturing: Flow meters are essential in manufacturing plants that use heating oil for process heating, helping to manage fuel usage and reduce operational costs.

Transportation: In the transportation sector, flow meters are used to monitor and control fuel consumption in vehicles and vessels powered by heating oil, improving fuel efficiency and reducing emissions.

Case Studies

To illustrate the benefits of using heating oil flow meters in various industries, consider the following real-life examples and case studies:

a) Our client, A manufacturing plant, that installed a heating oil flow meter to monitor and control fuel usage saw a 15% reduction in fuel consumption, resulting in significant cost savings.

b) Our client, A power plant, that upgraded its heating oil flow meter system experienced a 10% increase in overall efficiency, leading to increased energy production and reduced emissions.

Frequently

Asked

Questions

More Oil Flow Measurement Solutions

Top 3 Flow Meters for Oil

Diesel Flow Meter

Oval Gear Flow Meters with Better Price |Advantages and Disadvantages

Target Flow Meter Advantages And Disadvantages and Featured Applications

Ultra Low-Micro Liquid Flow Measurement

Water Flow Measurement Solution-Ultrasonic Flowmeter

Choosing the right heating oil flow meter for your business is crucial for improving fuel efficiency, reducing operational costs, and ensuring optimal performance. By considering factors such as accuracy, flow rate range, installation and maintenance requirements, and operating conditions, you can make an informed decision and select the best flow meter to meet your specific needs.

At Sino-Inst, we are an experienced manufacturer and supplier of high-quality heating oil flow meters tailored to your business requirements. Our team of experts can help you navigate the selection process and provide ongoing support to ensure you get the most out of your investment.

To learn more about our heating oil flow meter solutions and how they can benefit your business, contact us today.

-1.jpg)