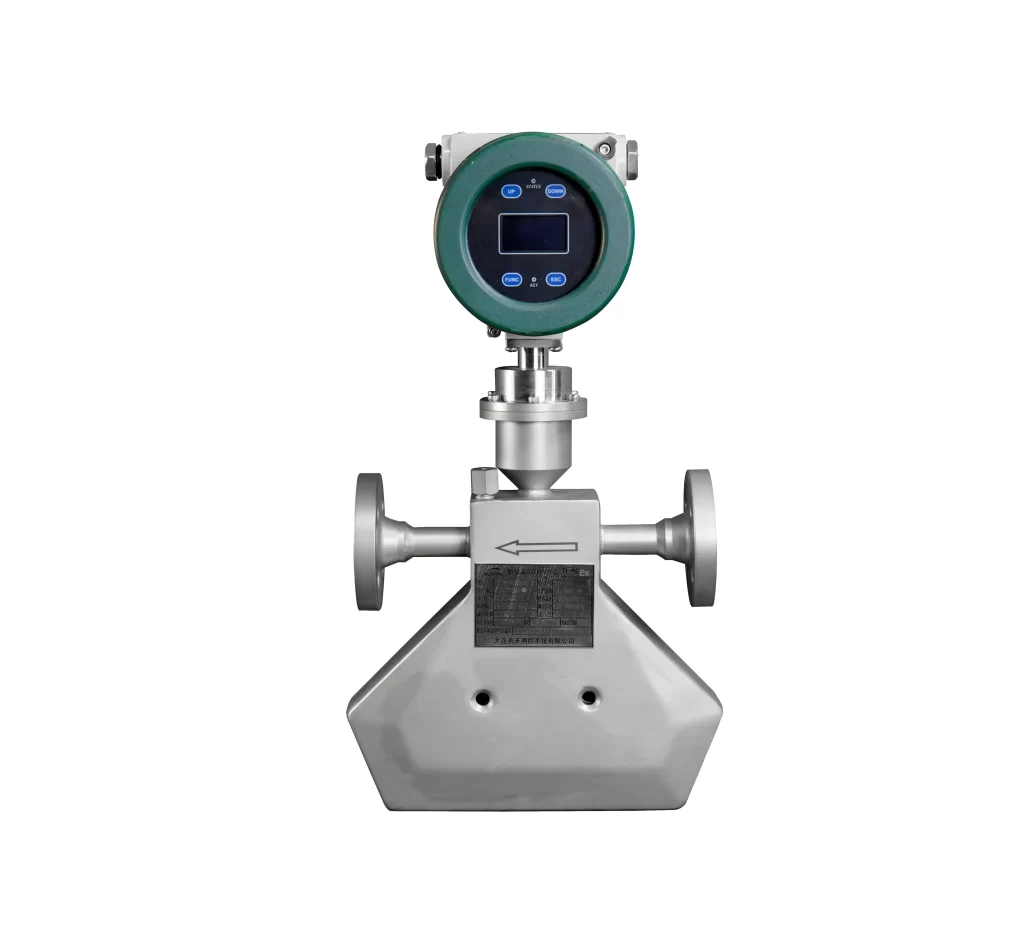

T Series Coriolis Mass Flow Meter has a triangular sensor structure. The smallest caliber can be DN3. This structure flow meter is easy to measure when the instantaneous flow is small, and it is easy to ensure the measurement accuracy.

Sino-Inst’s Coriolis Mass Flow Meter supports display of parameters such as instantaneous flow + cumulative flow + density + temperature. It also supports customization of high temperature, high pressure, etc.

Features

- Compact triangular shell structure, saving installation space;

- Simple installation, no upstream and downstream straight pipe section requirements;

- Completely provide mass flow, volume flow, density, temperature measurement and estimated parameters; reliable results can be obtained without tedious conversion, and the volume meter can be directly replaced;

- Ultra-high precision measurement;

- With stability and repeatability, there are no obstruction elements and moving parts in the fluid channel, which can be used in proportioning loading and trade transfer measurement occasions;

- Ultra-wide range ratio, can accurately measure gas

- High temperature can be customized.

- High pressure 4MPa, 10MPa, 30MPa can be customized (please consult engineers!).

T Series Coriolis Mass Flow Meter Technical Specifications

Sensor specifications, measuring range, zero point stability

| Diameter (DN) | Flow Range | Zero point stability |

| mm | kg/h | kg/h |

| 3 | 0~96~144 | 0.0144 |

| 6 | 0~540~810 | 0.081 |

| 8 | 0~960~1440 | 0.144 |

| 10 | 0~1500~2250 | 0.225 |

| 15 | 0~3000~4500 | 0.45 |

Note:

The flow range gives two parameters, the middle parameter is the standard flow range. Generally, factory inspection is carried out according to this range. It is also recommended that users choose instruments within this range. The latter parameter is the upper limit flow range that ensures stable operation of the sensor.

| Density (liquid) measuring range and accuracy: | Measuring range: 0.3~3.000g/cm3; Measuring accuracy: ±0.002g/cm3 |

| Temperature measurement range and accuracy: | Measurement range: -200~350℃ Measurement accuracy: ±1℃ |

| Working temperature of the measured medium: | -200℃~350℃ |

| Standard type: | -50~200℃ |

| Low temperature type: | -200~200℃ |

| Applicable ambient temperature: | -40℃~60℃ |

| Material: | Measuring tube 316L, Housing 304 |

| Working pressure: | 0~4.0MPa. Note: The actual withstand pressure of the sensor is different for each specification, here is just the standard withstand pressure. |

| Explosion-proof mark: | Exd[ia]ⅡCT6Gb |

Transmitter parameters

| Measuring parameters: | Mass flow, volume flow, medium working density, medium working temperature |

| Display: | Double-row LED display, three-row LCD display |

| Window size: | 62×32mm (W×H) (Φ80mm) |

| Measurement display accuracy: | 0.05% |

| Measurement display unit: | Mass flow: g/h, kg/h, t/h, g/m, kg/m, t/m Volume flow: cm3/h, dm3/h, m3/h, cm3/m, dm3/m, m3/m Density: kg/m3 or g/cm3 Temperature: ℃, K, ℉ |

| Converter output signal: | 0~10000Hz pulse signal, flow signal, open collector signal, 4~20mADC current signal, choose one of flow and density output signals; |

| Current output load capacity: | Not less than 750 ohms (24VDC power supply). Note: Two current signals can be provided as needed; |

| Output signal accuracy: | Pulse signal 0.05%; current signal 0.2%; |

| Communication signal: | RS485, MODBUS protocol |

| Operating ambient temperature: | -40~60℃ |

| Power supply: | 18~36VDC power supply: 7W (basic power supply) 85~265VAC power supply: 10W (additional power supply) |

| Instrument protection and explosion-proof protection level: | IP67 |

| Explosion-proof grade: | Exd[ia]ⅡCT6Gb Exd [ib]ⅡCT6Gb |

Coriolis Mass Flow Meter Principle

The Coriolis mass flowmeter works based on the principle of Coriolis force. When a fluid passes through a rotating system, due to the effect of inertia, the fluid will generate a force perpendicular to the flow direction. The magnitude of this force is proportional to the mass flow rate of the fluid. It has nothing to do with other properties of the fluid (such as density, viscosity, etc.). The Coriolis mass flowmeter determines the mass flow rate of the fluid by measuring this force.

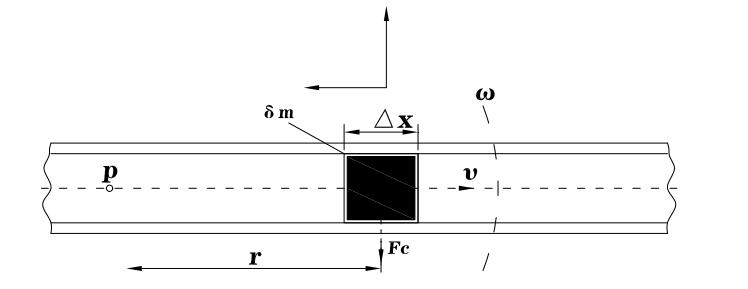

The metering system of a mass flowmeter includes a sensor and a transmitter for signal processing. The mass flowmeter is based on Newton’s second law: force = mass × acceleration (F = ma). When a particle with a mass of m moves at a speed V in a pipe rotating at an angular velocity ω about the P axis, the particle is subject to two components of acceleration and its force:

(1) Normal acceleration, that is, centripetal acceleration αr. Its magnitude is equal to 2ωr, toward the P axis;

(2) Tangential angular velocity αt, that is, Coriolis acceleration. Its value is equal to 2ωV, and its direction is perpendicular to αr.

Due to the compound motion, a Coriolis force Fc=2ωVm acts in the αt direction of the particle, and the pipe exerts a reverse force -Fc=-2ωVm on the particle.

When a fluid with a density of ρ flows at a constant speed V in a rotating pipe, any pipe with a length of Δx will be subjected to a tangential Coriolis force ΔFc: ΔFc=2ωVρAΔx (1)

Where A is the flow cross-sectional area of the pipe.

Since there is a relationship: mq=ρVA

So: ΔFc =2ωqmΔx (2)

Therefore, the mass flow rate can be measured by directly or indirectly measuring the Coriolis force of the fluid flowing in the rotating tube.

Coriolis Mass Flow Meter vs Magnetic Flow Meter

Mass flowmeter and electromagnetic flowmeter are two common flow metering devices. They play a very important role in industrial automation production. They can both be used to measure the mass or volume flow of fluids. But there are still some differences. The main differences between the two flowmeters are:

- Different measurement principles

Mass flowmeter is a flow measurement instrument developed based on the Coriolis force principle, which can directly measure the mass flow of fluids in closed pipes and the density of the medium.

Electromagnetic flowmeter measures the flow of fluids based on Faraday’s law of electromagnetic induction (that is, the magnitude of the induced electromotive force in a conductor is proportional to the rate of change of the magnetic flux in the conductor).

- Different scope of application

Mass flowmeter has a wide range of applications and can measure the flow of various liquid and gaseous media. It is suitable for application scenarios that require accurate measurement of mass flow. Such as flow measurement in chemical, pharmaceutical, food and other industries.

Electromagnetic flowmeter is suitable for flow measurement of conductive media. Such as acid and alkali liquids, electrolytes, sewage, etc. The measurement accuracy of non-conductive media such as petroleum, liquefied gas and other fluids is not high.

- Different accuracy and stability

Mass flowmeters have higher flow measurement accuracy for conditions such as high viscosity, large flow rate changes, and large temperature differences. It can reach ±0.2%~±0.5%.

Electromagnetic flowmeters are not affected by fluid temperature, temperature, turbulence, etc., and have high accuracy, which can reach ±0.5%.

- Different prices

Mass flowmeters have higher accuracy and stability, and are generally more expensive than electromagnetic flowmeters.

More Flow Measurement Solutions

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Use and Maintenance of Coriolis Mass Flowmeters

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

Coriolis Mass Flow Meter can measure multiple field variables such as flow, density, temperature, etc. at the same time. The transmitter has two output signals that can be configured separately. It can be used to display measured values such as flow, density, temperature, etc. One mass flow meter can replace multiple measuring instruments.

Sino-Inst’s T Series Coriolis Mass Flow Meter can be as small as DN3. It has a wide range of applications. In addition to normal fluid measurement, it can also measure industrial media that are difficult to measure with general fluid measuring instruments, such as high-viscosity fluids, various slurries, suspensions, etc.

If you need to purchase Coriolis Mass Flow Meter, or have related technical questions, please contact our engineers!

T Series Coriolis Mass Flow Meter for Small Flow DN3~DN15

T Series Coriolis Mass Flow Meter has a triangular sensor structure. The smallest caliber can be DN3. This structure flow meter is easy to measure when the instantaneous flow is small, and it is easy to ensure the measurement accuracy.

Product SKU: T Series Coriolis Mass Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 2999

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)