There are 2 common Types of Mass Flow Meters: Coriolis command flow meter and thermal mass flow meter. Mass Flow Meters accurately measure the mass flow of liquids or gases within pipes. A mass flow meter is more accurate than a traditional volumetric flow meter because it is not affected by factors such as temperature, pressure, density, etc.

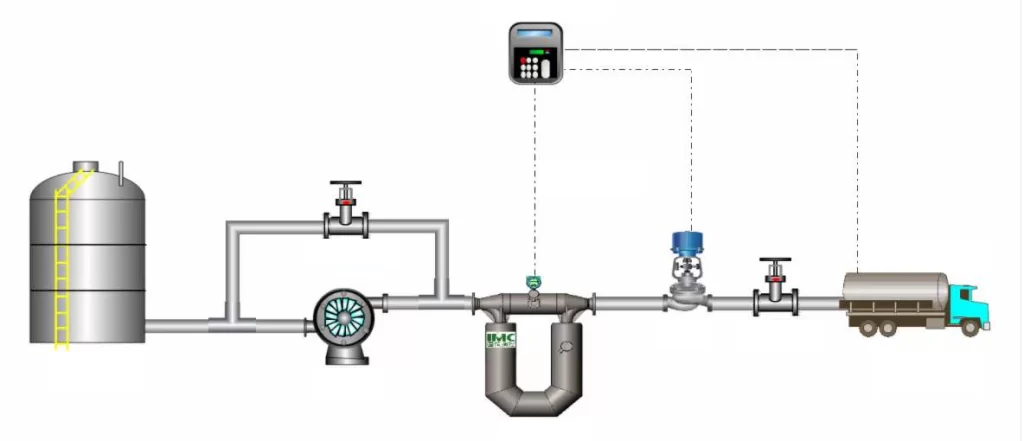

Usually used in industrial process control and flow regulation, batching, measurement, detection, etc. The volume of fluid is a function of fluid temperature and pressure and is a dependent variable, while the quality of fluid is a quantity that does not change with changes in time, space temperature, and pressure.

Coriolis Mass Flow Meter

Coriolis mass flow meters work based on the Coriolis force principle. It can directly measure the mass flow rate of fluid in a closed pipeline and the density of the medium. The Coriolis mass flowmeter is the most accurate flowmeter we offer at Sino-Inst.

Coriolis mass flow meter working principle

When fluid flows in a rotating tube, it will generate a force on the tube wall. It was discovered by Coriolis in 1832 when he was studying turbines, and is referred to as the Coriolis force. In 1977, the founder of Micro Motion in the United States developed the world’s first practical mass flow meter based on this principle.

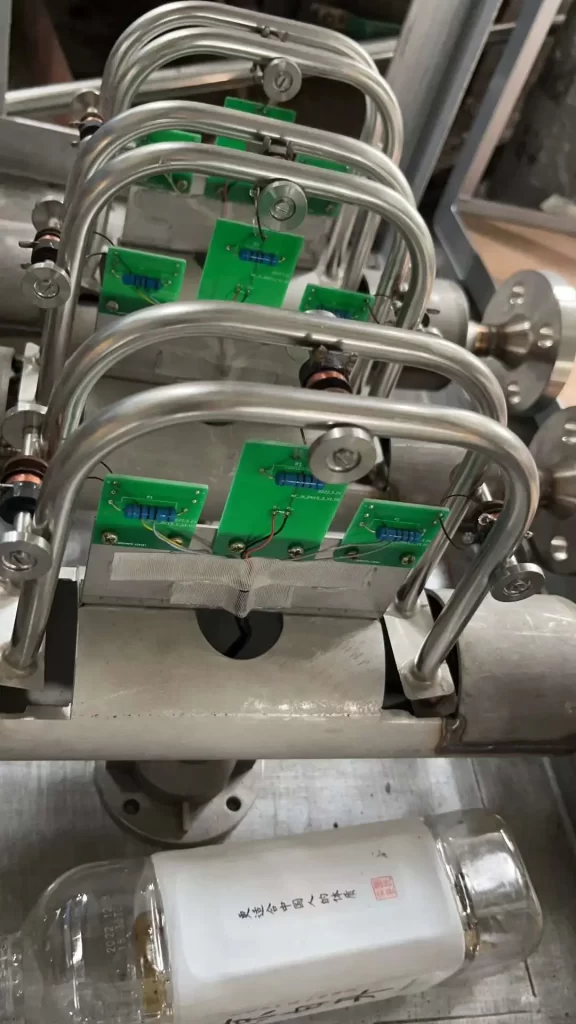

The mass flow meter is based on the Coriolis force. There are two parallel flow tubes inside the sensor, with a driving coil installed in the middle and detection coils installed at both ends. When the excitation voltage provided by the transmitter is applied to the drive coil, the vibrating tube vibrates in a reciprocating period.

When the fluid medium in the industrial process flows through the vibrating tube of the sensor, a Coriolis force effect will be generated on the vibrating tube, causing the two vibrating tubes to twist and vibrate. The detection coils installed at both ends of the vibrating tube will generate two sets of signals with different phases. The phase difference between these two signals is proportional to the fluid mass flow through the sensor. The computer calculates the mass flow rate flowing through the vibrating tube.

When different media flow through the sensor, the main vibration frequency of the vibrating tube is different, and the density of the medium is calculated based on this. The platinum resistor installed on the sensor vibration tube can indirectly measure the temperature of the medium.

Read more about: Coriolis Mass Flow Meter Technology

Advantages of Coriolis Mass Flow Meter

- Able to directly measure the mass flow of fluid (which is of great significance for the measurement and control of production processes such as energy metering and chemical reactions);

- High measurement accuracy (measurement accuracy can be guaranteed to be between 0.1% and 0.5%);

- The measurable ratio is large, and the measurable ratio that generally guarantees basic accuracy is 10:1 or 20:1;

- It has a wide range of applications. In addition to normal fluid measurement, it can also measure industrial media that are difficult to measure with general fluid measuring instruments. Such as high viscosity fluids, various slurries, suspensions, etc.;

- It can measure the density, temperature and other parameters of the measured medium online, and derive the concentration of the solute in the solution from this;

- The installation requirements are not high and there are no requirements for the upstream and downstream straight pipe sections;

- Reliable operation and low maintenance rate;

Applications

The characteristics of mass flow meters determine that flow meters can be widely used in the following fields:

Thermal Mass Flow Meter

Thermal Mass Flow Meter, abbreviated as TMF, is a commonly used gas mass flow meter. This flow meter works based on the thermal effect principle. It changes the temperature of the fluid by inputting heat into the fluid, and then calculates the mass flow rate of the fluid by measuring the temperature change of the fluid.

Thermal mass flow meters can be used as micro gas flow measurements or flow controllers.

Thermal mass flow meter working principle

The basic principle of a thermal mass flow meter is to measure gas flow by measuring the cooling effect of the gas flowing through the heating element in the flow meter.

There are two thermal resistance elements in the measurement section where the gas passes, one of which serves as a temperature detector and the other serves as a heater. The temperature sensing element is used to detect the gas temperature, and the heater maintains a constant temperature difference between its temperature and the temperature of the gas being measured by changing the current.

When the gas flow rate increases, the cooling effect becomes greater and the current required to maintain a constant temperature between the thermal resistors becomes greater. This heat transfer is proportional to the gas mass flow rate, that is, there is a corresponding functional relationship between the supply current and the gas mass flow rate to reflect the gas flow rate.

Read more about: Thermal Mass Flow Meter Technology

Advantages of Thermal mass flow meter

- A true mass flow meter does not require temperature and pressure compensation for gas flow measurement, and the measurement is convenient and accurate. The mass flow rate or standard volume flow rate of the gas can be obtained.

- Wide range ratio, can measure gases with flow rates as high as 100Nm/s and as low as 0.5Nm/s, and can be used for gas leak detection.

- Good seismic resistance and long service life. The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on measurement accuracy.

- Easy to install and maintain. If site conditions permit, non-stop installation and maintenance can be achieved. (Special customization required)

- Digital design. Overall digital circuit measurement, accurate measurement and easy maintenance.

- Using RS-485 communication or HART communication, factory automation, integration, and optional wireless remote monitoring can be realized.

- The power supply is optional AC220V, DC24V or AC220VDC24V dual power supply.

Applications

Indirect measurement of mass flow

Both Coriolis mass flowmeters and thermal mass flowmeters can directly measure the mass flow rate of gas or liquid. But sometimes, you can also choose a volume flow meter to indirectly measure mass flow.

The mass flow rate is calculated by measuring the pressure and temperature of the fluid. Its advantages include simple structure, low price and easy use. However, indirect measurement of mass flow has low accuracy and is sensitive to pressure and temperature changes of the fluid, making it unsuitable for high-precision measurement situations.

There are 3 main types of indirect mass flow meters:

- Combination of velocity flow meter and density meter;

- A combination of throttling (or target) flowmeter and positive displacement flowmeter;

- Throttle (or target) flow meter and density meter combination.

There is also a way to convert the measurement value of the volumetric flowmeter into the volumetric flow rate under standard conditions based on the working pressure and temperature of the fluid. However, it cannot give accurate mass flow when the type or composition of the medium changes.

Strictly speaking, it is not a mass flow meter. It outputs density, specific gravity, volume flow, mass flow, mass energy flow, etc., and has multiple functions such as indication, analog output, printing, limit-crossing alarm, and instrument failure alarm.

More about: Featured Volumetric Flow Meters

More Featured Flow Measurement Solutions

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Volumetric Flow Meters: Comprehensive Guide and Product List

- Choosing the Right Inline Water Flow Meter

- Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

- Industrial Inline Flow Meters | Selection List

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Understanding Types of Mass Flow Meters, their working principles, advantages and disadvantages, etc. can help us choose a more suitable mass flow meter! Different types of mass flow meters have their own advantages and disadvantages. Users should make comprehensive considerations based on actual needs and working conditions when choosing.

Most of the time, when we talk about mass flow meters, we mean the measurement of gases and liquids. In fact, we can also perform mass flow detection on powders. Read more about: Solid Flow Meter | Powder Mass Flow Measurement.

We at Sino-Inst supply more than featured 5 Types of Mass Flow Meters. Includes micro mass flow meter. Liquid measurement covers DN3~DN200, and gas measurement covers DN2~DN4000. Mass flow meters and mass flow controllers can be customized. If you need to purchase Mass Flow Meters or have related technical questions, please feel free to contact us.

-1.jpg)