A BTU meter, also known as an energy meter, is a device used to measure the heat energy generated or consumed in a heating or cooling system. A BTU meter, often a staple in the HVAC industry. Leveraging ultrasonic technology, these meters provide accurate readings, ensuring optimal performance of systems like chillers and other cooling or heating units. From portable designs for on-the-go engineers to digital and smart meters for seamless integration into modern infrastructure, BTU meters offer a range of options. In various industries, understanding these readings isn’t just about numbers; it’s about optimizing performance, ensuring energy efficiency, and, ultimately, driving profitability.

What BTU Stands For

BTU stands for British Thermal Unit, and it is a unit of measurement for energy. Think of it as a label or a measure, just like how we measure distance in miles or weight in pounds. Specifically, a BTU measures energy, but not just any energy – it focuses on heat. If we were to boil it down (pun intended!), one BTU represents the amount of energy needed to heat or cool one pound of water by one degree Fahrenheit.

In the context of heating and cooling systems, BTU is commonly used to measure the amount of heat that an HVAC system can produce or remove from a space. This measurement helps determine the appropriate size of HVAC equipment needed to adequately heat or cool a given area.

Additionally, BTU is also used to measure the energy content of fuels such as natural gas, propane, and heating oil, which helps determine the cost and efficiency of using these fuels for heating purposes.

What is a BTU Meter?

A BTU meter, often referred to as an energy meter, gauges the heat energy in heating or cooling systems. It operates by evaluating the flow rate and temperature disparity of a liquid as it courses through a heat exchanger.

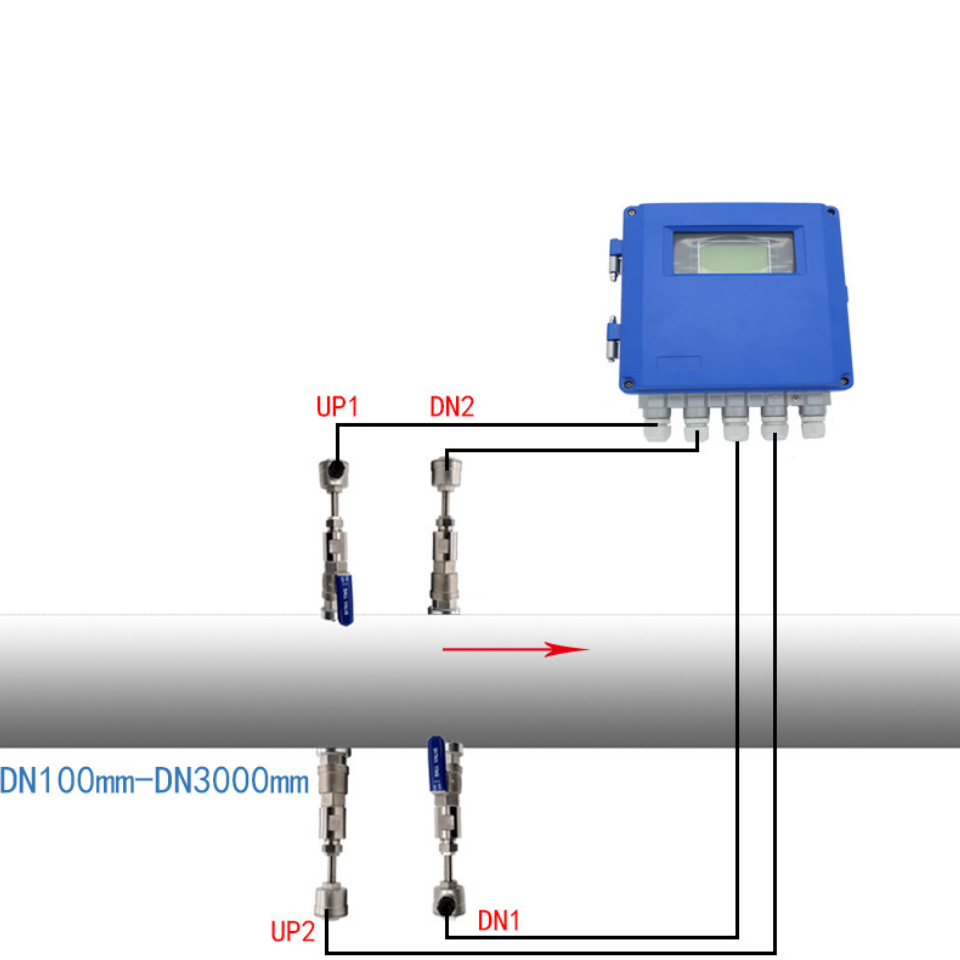

This meter is comprised of three main components: two temperature sensors, a flow sensor, and a calculator. These sensors are strategically positioned—one at the entrance and the other at the exit of the heat exchanger. The flow sensor tracks the liquid’s movement through the exchanger.

By comparing the readings from the entrance and exit temperature sensors, the meter identifies the temperature variation. Coupled with the flow rate data, the calculator determines the heat energy transfer within the exchanger.

With its precise heat energy readings, the BTU meter is invaluable for overseeing energy use in heating or cooling systems across commercial, industrial, and residential spaces. This data aids in enhancing HVAC system efficiency, pinpointing potential leaks or inefficiencies, and highlighting opportunities for energy conservation.

How Does a BTU Meter Work?

At the heart of many industries, BTU meters play an essential role in gauging the intricacies of heat energy. But how does it translate something so vast and complex into numbers we can understand? Let’s break it down, step-by-step.

Positioning the Sensors: The BTU meter uses two temperature sensors. Imagine them as thermometers—one is placed at the starting point (or the inlet) and the other at the finish line (or the outlet) of a heat exchanger.

Flow Sensing: Alongside the temperature sensors, there’s a flow sensor. Think of this as a turnstile at a stadium entrance—it counts how fast the liquid is moving through the heat exchanger.

Temperature Differential: Once our ‘thermometers’ have read the temperatures at the beginning and end, the BTU meter calculates the difference between these two readings. It’s like checking how much warmer a room becomes after turning on a heater for a certain period.

Crunching the Numbers: Using the flow rate from the ‘turnstile’ and the temperature difference, a built-in calculator deduces the heat energy transfer. Imagine you’re baking cookies. The number of cookies (flow rate) and how much they’ve baked (temperature difference) will determine if they’re perfectly golden or just half-baked.

Data Display: Finally, all this information gets presented on a display, offering a clear view of the heat energy involved.

To wrap it up, think of a BTU meter like a coach on a sports team. It watches the game (or heat exchange), takes notes (or measurements), and gives feedback (or readings) so that the team can play their best match. The data provided by the BTU meter can be used to optimize the operation of HVAC systems, detect leaks or system inefficiencies, and help identify areas for improvement in energy consumption.

Industrial BTU Measurement Systems

A BTU measurement system is a system used to measure the heat energy produced or consumed in a heating or cooling system. The system is based on British Thermal Units (BTU), which is the amount of heat energy required to raise the temperature of one pound of water by one degree Fahrenheit.

BTU measurement systems typically include BTU meters that measure the flow rate and temperature difference of the liquid passing through the heat exchanger. The instrument consists of two temperature sensors, a flow sensor and a calculator. One temperature sensor is placed at the inlet of the heat exchanger and the other is placed at the outlet of the heat exchanger. Flow sensors measure the flow rate of liquid through the heat exchanger.

The temperature difference between the inlet and outlet of the heat exchanger is measured by two temperature sensors. The flow of liquid is measured by a flow sensor. The calculator then uses this data to calculate the amount of thermal energy transferred through the heat exchanger.

BTU measurement systems are used in a variety of applications, including commercial, industrial, and residential environments. It can be used to monitor the energy consumption of a heating or cooling system, optimize the efficiency of an HVAC system, detect leaks or system inefficiencies, and help identify areas for improvement in energy consumption.

In general, BTU measurement systems are an important tool for measuring and monitoring the heat energy produced or consumed in a heating or cooling system, helping to optimize the efficiency of your HVAC system and reduce energy consumption.

Types of BTU Meters

In the expansive realm of energy measurement, BTU meters stand out as pivotal tools. They come in various types, each tailored for specific applications and environments. Here’s a concise look at some prominent types and their unique attributes:

Electromagnetic BTU Meters:

These meters harness the principle of electromagnetic induction. As the fluid, with its inherent electrical conductivity, flows through a magnetic field, it generates a voltage that is directly proportional to the flow rate. This makes these meters highly accurate and suitable for various liquids.

Best for: Industries requiring precise measurements, especially where the fluid has a good level of conductivity.

Ultrasonic BTU Meters:

Ultrasonic meters leverage sound waves to determine flow rate. They shoot waves across the flow of the fluid, and any change in frequency (due to the Doppler effect) gives a clear picture of the flow rate. Being non-invasive and without moving parts, they promise longevity and reliability.

Best for: Situations demanding high precision, modern infrastructures, and places valuing consistent, long-term accuracy.

Portable BTU Meters:

These compact, mobile meters are designed for temporary measurements. They can swiftly be attached, readings procured, and then they can be relocated as needed.

Best for: Spot-checks, mobile monitoring, or when you need to assess multiple sites in quick succession.

Thermal Dispersion BTU Meters:

These utilize the principle of heat dispersion. When a heated object is placed in a flow path, the rate at which it cools can help determine the flow rate. They’re notable for their direct mass flow measurement capability.

Best for: Industries like wastewater management and chemical processing, where the direct mass flow rate is crucial.

Vortex Shedding BTU Meters:

As the fluid flows past a bluff body, it creates vortices or swirling patterns. The frequency of these vortices relates directly to the fluid flow rate. This makes the vortex shedding meter a reliable choice for many applications.

Best for: Operations where varied flow rates and fluid densities come into play, like petrochemical and manufacturing processes.

In essence, the selection of a BTU meter pivots on your industry’s unique demands. From the electromagnetic wonders to the innovative vortex shedding meters, the right BTU meter awaits to optimize your operations.

Applications of BTU Meters

BTU meters, with their precision and versatility, aren’t restricted to just one domain. Instead, they find applications in varied sectors, each leveraging the device’s prowess in measuring heat energy. Let’s delve into where these meters shine:

Residential Use:BTU meters in residential settings help homeowners track energy usage of their heating and cooling systems. Monitoring home heating systems, tracking energy in multi-story buildings, and ensuring a comfortable living environment.

Industrial Applications:

Industries, be it manufacturing, chemical processing, or food and beverage, often require extensive heating or cooling processes. BTU meters here aid in keeping a close watch on energy consumption, crucial for maintaining product quality and safety standards. Moreover, precise measurement aids in detecting inefficiencies or leaks, safeguarding the bottom line.

HVAC Systems:

Heating, Ventilation, and Air Conditioning (HVAC) systems lie at the heart of creating comfortable environments, be it in offices, malls, or airports. BTU meters in HVAC settings ensure systems operate at peak efficiency, maintaining optimal temperatures while conserving energy. Regular monitoring can also pre-empt system failures or inefficiencies, ensuring uninterrupted comfort.

Renewable Energy Systems:

As the world pivots to greener energy sources, BTU meters find their role in monitoring systems like solar thermal installations or geothermal energy setups. By measuring the energy output and efficiency of these systems, stakeholders can assess system performance, ensuring they harness the maximum energy from renewable sources.

To conclude, from homes to vast industrial landscapes, the significance of BTU meters spans wide. They stand as unsung heroes, ensuring energy is used wisely, costs are saved, and sustainability goals are achieved.

Choosing the Right BTU Meter

Selecting the perfect BTU meter is crucial for accurate energy management. Here’s a concise guide to help you navigate your options:

- Environment: Assess where the meter will be used. Some are tailored for harsh industrial conditions, while others suit residential settings.

- Flow Rate: Ensure the BTU meter matches your system’s flow rate. Meters vary in their capacity to measure high or low flows.

- Features: Decide between digital or analog displays. Consider if smart connectivity for remote monitoring is needed.

- Durability vs. Cost: A slightly higher initial cost might offer a longer lifespan with less maintenance.

- Accuracy: Always prioritize precision, especially in industrial setups where small errors can have big implications.

- Brand Reputation: Established brands might offer better support and warranty, ensuring peace of mind post-purchase.

In essence, understanding your needs and being informed will lead you to the ideal BTU meter for your setup.

Most of the flow meters we supply at Sino-Inst can be customized into BTU meters.

More Flow Measurement Solutions

Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

Volumetric Flow Meters: Comprehensive Guide and Product List

Choosing the Right Inline Water Flow Meter

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

Industrial Inline Flow Meters | Selection List

At Sino-Inst, we pride ourselves on our rich experience as manufacturers and suppliers in this field. Our deep industry knowledge ensures that you get nothing but the best.

Why settle for generic when you can have a BTU meter tailored to your needs? As experienced manufacturers, we at Sino-Inst support customization to meet your unique requirements. Reach out today, and let’s work together to find your perfect BTU metering solution.

-1.jpg)