Cryogenic Flow Meters – Multiple technologies for monitoring the flow rates of cryogenic fluids.

Cryogenic Flow Meter can be used to monitor the flow rate of cryogenic fluids. Common industrial cryogenic fluids are O2, N2, Ne, H2, He and so on. Liquid oxygen, liquid nitrogen, liquid argon, liquid ammonia, and liquefied gas (LNG) are cryogenic liquids. So flow measurement for cryogenic fluids is very important.

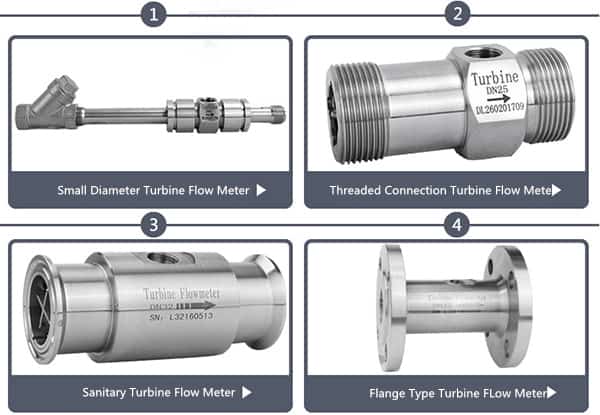

To handle fluid temperatures down to 328°F (-200°C), Sino-Inst manufactures high quality Cryogenic Flow Meters. Turbine flowmeter is the most widely used cryogenic flowmeter. Coriolis Mass, Precession Vortex and DP Flow Meters also are good choice for cryogenic fluids.

Please feel free to contact Sino-Inst for Free Technical Support.

Featured Cryogenic Flow Meters

Tchnologies for Cryogenic flow measurement

Differential Pressure for Cryogenic

Differential Pressure Flow Meters also called DP flow meters. Differential pressure flow meters consist of flow sensors and pressure/differential transmitters. DP Flow Meters measure the flow rate based on the differential pressure measured by the flow sensor parts. Flow sensors are the important part of differential pressure flow meters. Like: Orifice plate, Venturi tube, Wedge, V-cone and Averaging Pitot Tubes.

Differential pressure (DP) flow meters are suitable for applicaitons, like: water, gas, steam, oil….

Turbine for Cryogenic

A turbine flow meter is a Volume flowmeter. Turbine flow meters use the mechanical energy of the liquid or gas to rotate a rotor in the flow stream. The velocity of the turbine rotor is proportional to the velocity of the fluid passing through the flow meter. The frequency of the signal relates directly to flow rate. The vaned rotor is the only moving part of the flow meter. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, diesel, water, cryogenic liquids, air, and industrial gases.

Coriolis Mass for Cryogenic

Coriolis mass flow meter also called micro motion flow meter. Coriolis mass flow meter is the mass flow meter beasd on the coriolis force. Coriolis mass flow meter and thermal mass flow meter are the most common mass flow meters. Corolis mass flow meters are best choice for all process and custody transfer (CT) applications. Coriolis mass flow meter can measure different values at the same time. Mass, volume flow, density and concentration measurement of liquids and gases. This is the most important difference among Coriolis mass flow meter, DP and oval gear flow meters.

Vortex for Cryogenic

A turbine flow meter is a Volume flowmeter. Turbine flow meters use the mechanical energy of the liquid or gas to rotate a rotor in the flow stream. The velocity of the turbine rotor is proportional to the velocity of the fluid passing through the flow meter. The frequency of the signal relates directly to flow rate. The vaned rotor is the only moving part of the flow meter. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, diesel, water, cryogenic liquids, air, and industrial gases.

Technical Facts

Turbine flow meters are traditional cryogenic flow meters. Simple to use and cost-effective.

Target type flowmeter is a new type of low temperature flowmeter. The target type flowmeter is also suitable for flow measurement of high temperature (+ 700 ° C) fluid. Higher price.

Let’s take a look at their technical parameters.

Cryogenic Turbine Flow Meter

1. Ambient temperature: -20 ~ + 50 ℃;

2. Relative temperature: 5% ~ 95%;

3. Medium temperature: -196 ℃ ~ normal temperature

4. Explosion-proof grade: ibⅡBT4;

5. Medium pressure: 1.6MPa, 2.5Mpa, 4.0Mpa, 16Mpa, 25Mpa, 32Mpa, 42Mpa;

6. Output mode: pulse output or 4 ~ 20mA two-wire system;

7. Installation method: thread connection, flange connection, spherical seal thread connection;

8.Nominal diameter: DN15, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN200

Features

- Simple, durable design

- Easy installation and maintenance

- Reliable operation under a wide range of temperatures and pressures

- Turndown ratio is up to 35:1

- Good level of accuracy at an economic price

- Wide variety of process connections

- Low pressure drop

Turbine Meter Advantages

- Wide flow rangeability including low flow rates

- Turndown ratio is up to 35:1

- Good level of accuracy at an economic price

- Simple, durable construction

- Easy to install and maintain

- Flexible connection to flow instruments for flow control

- Wide variety of process connections

- Turbine meters can operate over a wide range of temperatures and pressures

- Low pressure drop across the turbine

Cryogenic Target Flow Meter

1.Diameter: Φ10 ~ Φ2000, larger pipe diameter can be customized

2.Temperature: -196 ° C ~ 500 ° C

3.Pressure: 0 ~ 42MPa

4.Medium: gas, liquid (including high viscosity liquid, slurry), steam;

5.Velocity of flow: Suitable for low-velocity media, its measurable minimum flow rate is 0.08m / s

6.Output: LCD display, and 4 ~ 20mA, 0 ~ 10V, impulse or RS485 (Optional)

7.Material of measure tube: Carbon Steel; 304; 316L; Being able to provide other according to user requests

8.Explosion- Prevent Symbol: ExiallCT4, ExiallBT4

Features

- Accurate measurement, accuracy can reach 0.2%;

- Good repeatability, generally 0.05% to 0.08%, fast measurement;

- Can change the range of resistance (target) according to actual needs;

- Low-power battery on-site display, can directly read the displayed value online. And the display can read the instantaneous and cumulative flow and percentage bar graph at the same time;

- Simple and convenient installation and extremely easy maintenance;

- Multiple output formats, which can transmit various parameters remotely;

- Strong vibration resistance, pulsating flow can be measured within a certain range.

Advantages of throttling differential pressure flowmeter (orifice flowmeter)

- The standard orifice plate structure of the throttle piece is easy to copy. Simple, firm, stable and reliable in performance, long in service life and low in price;

- The throttling application range is extremely wide. All single-phase fluids, including liquid, gas, and steam, can be measured. Some mixed-phase flows, such as gas-solid, gas-liquid, liquid-solid, etc. can also be applied. General production processes and pipe diameters. The working condition (pressure, temperature) has products;

- All accessories can be used by all manufacturers if it is an international standard and can be used without calibration.

Applications of Cryogenic Flow Meters

At LNG plants, terminals and storage facilities natural gas is handled in liquefied form at temperatures around -260 °F. Orifice flowmeters are a good choice for LNG flow.

The ultra-low temperature liquid LNG flowmeter uses a symmetrical porous structure design. In addition to the advantages of simple, reliable, safe, and wide application of standard throttling devices, it also has high accuracy, low requirements for straight pipe sections, wide range ratio, and permanent pressure loss.

At the same time, it also overcomes the shortcomings of debris retention, blockage and sharp edges of the standard throttling device. Which are easy to wear and tear, and high maintenance and verification costs. It has broad development prospects.

Application range of cryogenic liquid LNG flowmeter:

Cryogenic liquid flowmeter Can be applied to the measurement of gas, liquid, liquid gas, dirty media, slurry.

Technical parameters of extremely low temperature liquid LNG flowmeter:

- Medium range: gas, liquid, steam, gas-liquid mixed medium

- Nominal diameter: DN15 ~ 3000

- Connection method: clamping connection, flange connection

- Accuracy: ± 0.5%

- Repeatability: ± 0.2%

- Turndown ratio: 10: 1

- Front and rear straight pipe requirements: first 3DN, rear 1DN

- Reynolds number applicable range: 200 ~ 10000000

- β value range: 0.25-0.85

- Medium temperature range: -200 ℃ ~ -600 ℃

- Medium pressure range: ≤42Mpa

- Material range: CS, 0Cr18Ni9, 316, 316L, HB and HC

- Flange standards: American standard, German standard, national standard, etc. Special standards according to user requirements

How does a cryogenic flow meter work?

Theory of Operation

Turbine Flow Meter Equation

Technical Support

Natural Gas Flow Meter

Natural Gas Flow Meter, is the inline flow meter for natural gas pipeline. Like: thermal mass flow meter, ultrasonic natural gas flow meter, natural gas turbine flow meter. Intelligent Gas Precession Vortex Flowmeter, and differential pressure flow meter. These are the most common inline natual gas flow meters with digital display. According the natural gas pipeline measurement conditions, select suitable natural gas flow meter.

Steam Flow Meters

Steam flow meters are digital flow meters for steam flow measurement. A variety of technologies are suitable for steam flow measurement. Common types are: Vortex flow meter. Differential pressure flow meters and portable ultrasonic flow meters works too. Other technologies to measure steam, like Coriolis flow meters. But the price vs the advantages against vortex or DP flowmeters are not justifying the price of a coriolis flow meter.

Inline Compressed Air Flow Meters

Compressed Air Flow Meter is the digital flow meter work for the air compressor. Thermal mass, vortex, portable ultrasonic, and DP flowmeters are commom gas flow sensors. Air consumption is an important info for industrial inline gas flow pipe. Compressed air is the most expensive form of energy in manufacturing plants. And compressure air accounts for up to 20% of the overall energy costs. So, It is important to measure compressed air flows precisely in all conditions.

Thermal Mass Flow Meter Technology

Thermal Mass Flow Meter (TMF) also called Thermal Flow Meter. Thermal Mass Flow Meters measure the mass flow of a fluid. An external heat source will heat the pipe or the fluid. Temperature field changes when the fluid flows through the pipe. Thermal mass flow meter measures the relationship between the energy required to increase the temperature of a fluid and the mass of the fluid to measure the mass flow of the fluid. The flowmeters directly measure the mass flow or normalized volume flow of gases.

-1.jpg)