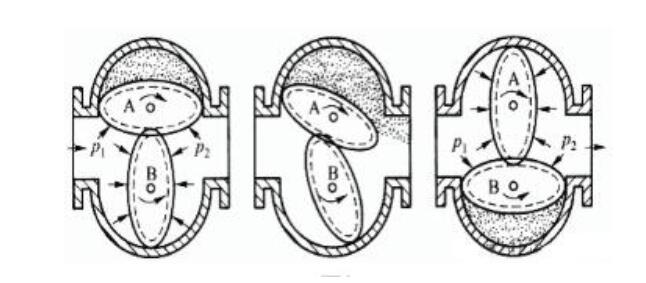

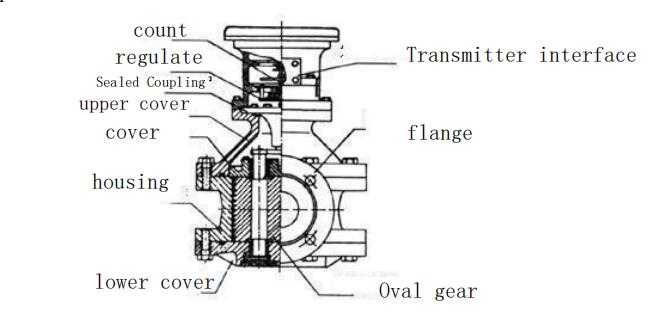

Oval Gear Flow Meters, also known as positive displacement flow meter, is a commonly used positive displacement flow meter. It is a class with higher precision in flow meters.

Oval Gear Flow Meters are used for precise continuous or intermittent measurement of the flow or instantaneous flow of liquid in the pipeline. It is especially suitable for flow measurement of heavy oil, polyvinyl alcohol, resin and other media with high viscosity.

oval gear flow meter price

Part of the reason for choosing an oval gear flow meters is that the price of oval gear flow meter is relatively moderate.

What are the factors that affect the price of oval gear flow meters?

Mainly include:

- Diameter

- Material

- Temperature

- Pressure

- Flow range

- Return to zero function

- Mechanical display

- Electronic display

- Signal output

- High viscosity media

Here we provide you with the reference price of the oval gear flow meters with the following configuration:

- Flange connection;

- Cast iron material;

- Accuracy level 0.5;

- The mechanical meter shows the accumulation (the meter can display the current flow when it is brought back to zero);

- Applicable temperature range: -20℃~+80℃;

- Protection class IP65

Reference: Oval Gear Flow Meter Price (USD/SET)

| Diameter | DN10 | DN15 | DN20 | DN25 | DN40 | DN50 | DN65 | DN80 | DN100 | DN150 | DN200 |

| Cast iron material | 295 | 300 | 315 | 335 | 345 | 435 | 545 | 608 | 915 | 2465 | 3200 |

Featured Oval Gear Flow Meters For Sale

Learn More About Oval Gear Flow Meters

If you cannot find an answer to your question in our Oval Gear Flow Meters, you can always contact us and we will be with you shortly.

More Featured Liquid Flow Meters

More Flow Measurement Solutions

Sino-Inst is a manufacturer of Oval Gear Flow Meters. We offer more than 10 Oval Gear Flow Meters with better prices. Oval Gear Flow Meters include high viscosity, high temperature, high pressure and other types.

The oval gear flowmeter is a type of positive displacement flowmeter. It is especially suitable for measuring the flow rate of heavy oil, diesel oil, lubricating oil, polyvinyl alcohol, resin and other media with high viscosity. Therefore, the oval gear flow meters are also generally called an oil meter. The sum of the liquid flow through the pipeline can be read directly. Widely used in petroleum, chemical, pharmaceutical and other industries.

If you just need to purchase an oval gear flowmeter, you can learn more about the price, advantages and disadvantages of oval gear flowmeters through this article.

If you have any technical questions when purchasing an oval gear flow meters, please feel free to contact us.

-1.jpg)