Pipeline flow meters are an integral part of fluid flow monitoring and management in industrial pipelines. Pipeline Flow Meters measure the volume or rate of fluid flow (whether liquid, gas or steam) flowing through a pipeline, providing important data for process control and billing. Their importance goes beyond measurement; they are critical to ensuring operational efficiency, maintaining system integrity and optimizing resource usage.

Featured Pipeline Flow Meters for DN6~DN1000~DN6000

Top 4 Types of Pipeline Flow Meters

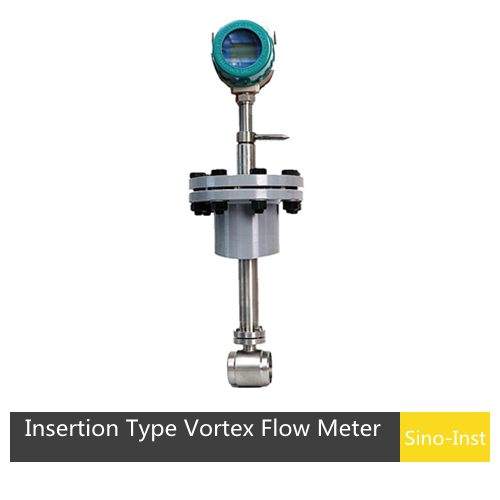

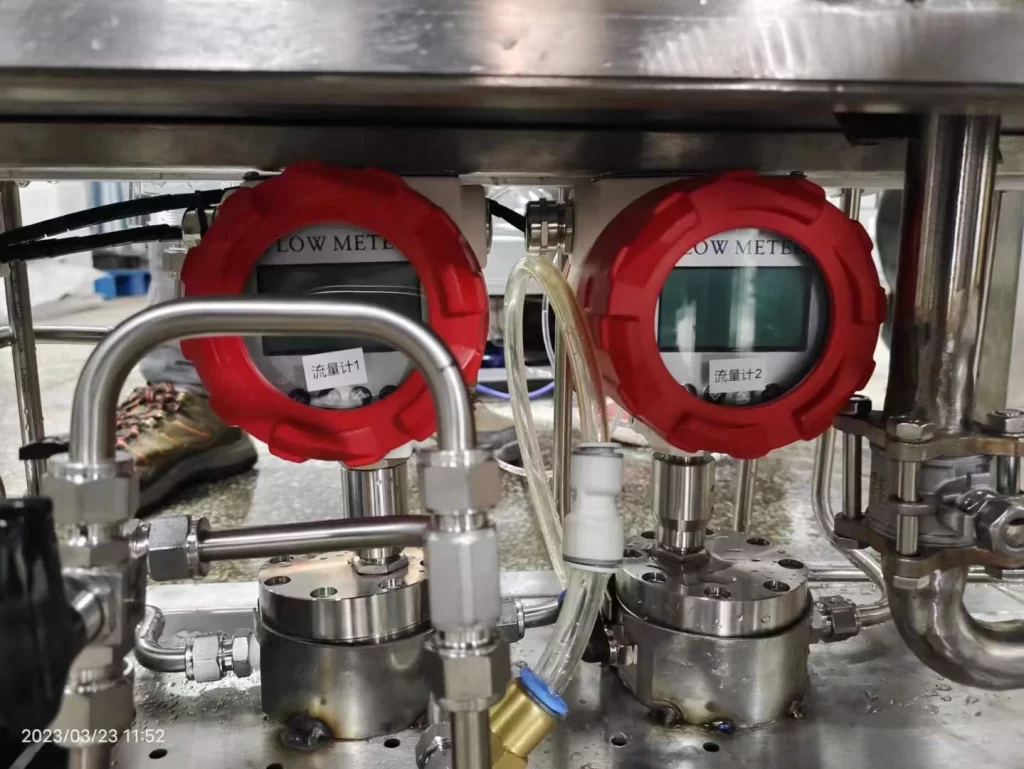

In our usual industrial process measurement and control, the most commonly used are electromagnetic flowmeters, turbine flowmeters, ultrasonic flowmeters and vortex flowmeters. These flow meters are also our highest selling products at Sino-Inst.

Next, let’s take a detailed look at the comparison of their four Pipeline Flow Meters.

| Item | Electromagnetic Flow Meter | Turbine Flow Meter | Ultrasonic Flow Meter | Vortex Flow Meter |

| Measurement Principle | Measures the voltage generated by a fluid passing through a magnetic field | Uses a rotating turbine to measure flow rate | Uses sound waves to measure the rate of flow | Measures vortices shed by a bluff body placed in the flow |

| Fluid Types | Conductive fluids (e.g., water, acids) | Liquids and gases | Wide range, including non-conductive fluids | Liquids, gases, and steam |

| Installation Impact | Requires full pipe and no flow obstructions | Intrusive, may cause pressure drop | Non-intrusive options available | Intrusive, minimal pressure drop |

| Accuracy | High (±0.5% of reading) | Moderate to high (±0.5-1%) | Moderate to high (±1-2%) | Moderate (±1-2%) |

| Maintenance Requirements | Low, no moving parts | Higher, due to moving parts | Low for clamp-on models | Low, no moving parts |

| Cost | Moderate to high | Low to moderate | Moderate to high | Moderate |

| Pipe Size Range | Wide range DN10~DN2000 | DN4~DN300 | Very flexible, DN15~DN6000. Suitable for large diameters | DN15~DN1000 |

| Temperature Range | -40℃~120℃ | -200℃~180℃ | -30℃~90℃ -30℃~160℃ | -40℃~350℃ |

| Applications | Water/wastewater, chemical, food & beverage | Oil & gas, water, chemicals | Water management, large diameter pipes | Steam, gas, and low viscosity liquids |

| Special Considerations | Requires conductive fluids | Affected by fluid viscosity and density | Accuracy depends on flow profile and pipe installation | Vortex shedding can be affected by flow disturbance |

More about Flow Meter Technologies:

In fact, through the price comparison in the above table, we can already initially select the appropriate flow meter type for most measurement applications. Based on our many years of flow meter supply experience at Sino-Inst, we have compiled a Pipeline Flow Meters Selection Guide for your reference.

Selection Guide

Selecting the right type of flow meter is crucial for achieving accurate and reliable measurements in various industrial applications.

Considerations for Selection:

- Fluid Type

Electromagnetic: Ideal for conductive liquids such as water, wastewater, and chemicals.

Turbine: Suitable for clean liquids and gases, particularly in the oil and gas sector.

Ultrasonic: Best for a wide range of fluids, including those with low conductivity and large-diameter pipes.

Vortex: Effective for steam, gas, and low-viscosity liquids. - Installation Constraints

Pipe Size: Consider electromagnetic and ultrasonic meters for very large diameters (DN6000). Turbine and vortex meters are more suitable for small to medium diameters.

Space and Access: Depending on your pipe size, find out the straight pipe section requirements for each type of flow meter. - Accuracy and Range

High Accuracy Needs: Electromagnetic and turbine meters generally offer higher accuracy.

Wide Flow Range: Ultrasonic and vortex meters provide a broader flow range. - Cost Considerations

Flow meter price: For small pipes, the prices of various flow meters may not differ much. But for large-diameter pipes, the price difference will be greater. For example, for large-diameter water pipes, ultrasonic flow meters (clamp-on or plug-in types) will be more cost-effective than electromagnetic flow meters.

Initial vs. Long-term Cost: Turbine meters may have lower initial costs, but consider maintenance and lifespan. Electromagnetic and ultrasonic meters, while more costly upfront, may offer savings over time due to lower maintenance needs. - Measurement parameters are compatible with:

Finally, you can take your measurement parameters with our engineers for confirmation. include:

Measuring medium:

Pipe diameter:

Flow range:

temperature:

pressure:

Media density:

Installation method and dimensions:

Signal output:

FAQ

More Flow Measurement Solutions

- Flow Measurement 101

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Top Guide to CO2 Flow Meters

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Oval Gear Flow Meters with Better Price |Advantages and Disadvantages

- Brewery Flow Meters for Beer and Wine | Electromagnetic and More

- What Is Turbine Flow Meter K Factor?

- Ultra Low-Micro Liquid Flow Measurement

- Use and Maintenance of Coriolis Mass FlowmetersIndustrial Nitrogen Gas Flow Meters

- Industrial Liquid Nitrogen Flow Meters

- High Viscosity Flow Meters

- Diesel Flow Meter

- Wastewater flow meter

- Water Flow Meter Types

- Flowmeter Calibration & Recalibration

As we’ve explored today, understanding the right type of pipeline flow meter for your specific needs is crucial. Whether it’s electromagnetic, ultrasonic, turbine, or vortex flow meters, each type has unique features and applications.

At Sino-Inst, we don’t just specialize in pipeline flow meters. We’re also experts in measuring other critical aspects like crude oil flow, liquid level, and temperature. So, if you’re looking for comprehensive solutions for your measurement needs, we’ve got you covered. Discover more and get in touch with us today!

-1.jpg)