What is a water flow meter? A water flow meter is a device dedicated to measuring and displaying the instantaneous and cumulative flow of water. Industrial water flow meters have more powerful functions than water meters. Water flow measurement is essential for industrial applications such as wastewater treatment.

There are many different types of water flow meters on the market, including mechanical, electronic and intelligent types. Sino-Inst will explain the Industrial Water Flow Meter Types and Selection Guide to you based on our many years of experience. I hope it will be helpful to you.

Water Flow Meter Types

In principle, water flow meter types are: Electromagnetic (magnetic), Turbine, Ultrasonic, and DP. Coriolis and Oval Gear flow meters can also work for water flow measurement. These water flow meters, optional with digital display, battery, analog or pulse output. Material can be 316 stainless steel or special material.

Here we will analyze and introduce them to you in turn.

1. Magnetic Flow Meter for Water Flow Measurement.

Among the instruments for measuring water flow, the reason why the electromagnetic flowmeter has become the first choice is mainly due to its unique advantages and universality of aqueous solutions. As long as it is a conductive liquid with a dielectric conductivity of ≥5μS/cm, it can be stably measured without additional calibration.

For example, tap water, drinking water, seawater, sewage, acid-base aqueous solutions, and even mud. Electromagnetic flowmeters are all compatible.

FEATURES OF MAGNETIC FLOWMETERS:

- Design Pressure: 20 BARS to 172 BARS

- Design Temperature: Upto 120 deg.C with teflon liners / 180 Deg.C with ceramic liners

- Sizes: 2.5 mm to 3000 mm

- Fluids : Liquids (clean/ corrosive/dirty/viscous/ slurry)

- Velocity range: 0.1 to 10 m/s

- MOC: Liners: ceramic/ teflon/rubber : Electrodes: Platinum/ hastelloy/SS

- Accuracy: It varies from ±0.5% to ±1% of actual flow.

- Rangeability is 10:1

- Upstream length/ Downstream straight length is 10 / 5.

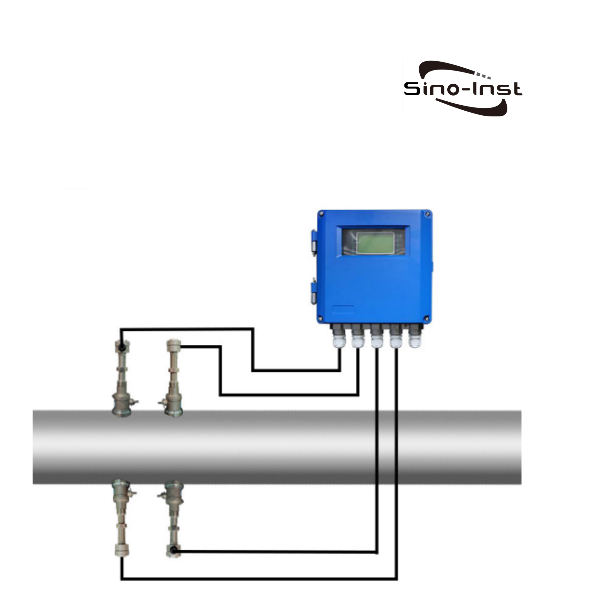

2. Ultrasonic Flow Meter – Non Contact

Ultrasonic flowmeters have their own unique and irreplaceable function, that is, non-contact measurement. For those who do not want to or cannot cut off the pipeline and directly measure the flow, the clamp-on ultrasonic flowmeter is a perfect choice.

Of course, ultrasonic flowmeters also have relatively high requirements for the medium. Basically, a clean and single liquid medium is required for measurement.

Advantages of ultrasonic flowmeter:

- You can choose portable, handheld, wall-mounted, or modular host;

- Clamp-on sensor can meet the pipe measurement of DN6 to DN6000;

- Better price;

- Clamp-on sensor is easier to install;

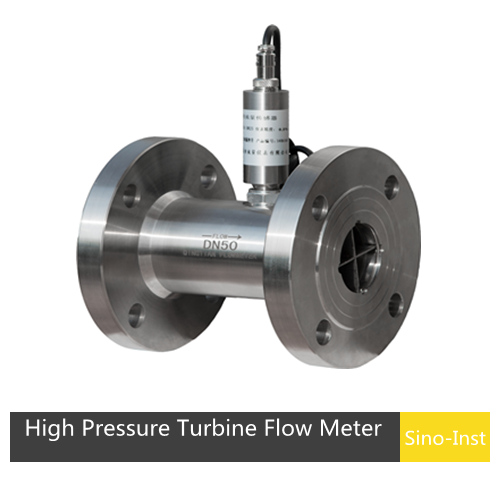

3. Liquid Turbine Flow Meter

The turbine flowmeter uses the principle that the rotation speed of the turbine is proportional to the water flow speed to measure the flow rate. It is suitable for measuring non-corrosive liquids. Such as water, oil, fuel oil, diesel. It is more suitable for clean, low-viscosity liquids.

However, the liquid turbine flowmeter is greatly affected by the viscosity and density of the liquid, and is easily affected by coarse particles and water rust. It is easy to produce errors.

- Compact structure, easy to install.

- Fast response speed, can measure instantaneous pulsating flow.

- Has a certain pressure tolerance.

4. Positive Displacement Flowmeter – Gear Type

The gear flowmeters we mainly sell are oval gears and spur gears. Oval gear flowmeters can be mechanical flowmeters, do not require power supply, and have stable performance. GF series circular gear flowmeters are suitable for measuring small flow rates. And they can meet requirements such as high temperature and high pressure.

Of course, gear flowmeters also have higher requirements for the cleanliness of aqueous solutions. If there are foreign particles, the gears may get stuck.

Gear Flow Meters Benefits:

- Compatible with high viscosity solutions;

- Customizable materials such as cast aluminum, cast iron, cast steel, stainless steel, PTFE, etc.;

- -200℃, 200℃, high and low temperature styles.

- Can be mechanical or configured with digital display and signal output.

- No front and rear straight pipe sections are required for installation, even hoses can be installed.

The 4 types mentioned above are the most commonly used types of water flow meters. Of course, according to your actual measurement parameters, you can also choose a metal rotor flow meter, a mass flow meter, or a differential pressure flow meter to measure.

If you don’t know how to choose, you can contact our engineers. Next, let’s talk about how to choose a suitable water flow meter.

How to choose a suitable water flow meter?

In order to choose a suitable water flow meter, we must first understand our measurement conditions and our measurement requirements.

- Water conditions. For example, seawater, tap water, sewage, or acid-base aqueous solution, etc.

- Pipeline diameter

- Flow range

- Temperature

- Pipeline pressure

- Signal output requirements

- Accuracy requirements

- Budget

Based on the above parameters, we can basically choose a suitable water flow meter.

More Flow Measurement Solutions

- Cryogenic Flow Meters Custom Cases

- Customer Case: Customized DN10 Flow Meter for Petrol

- Variable Area Flow Meter Case: Oxygen Flow Measurement

- Negative Pressure-Vacuum Flow Meters

- Annubar Flow Measurement: Principles, Applications, And Advantages

- Insertion Magnetic Flow Meter | Better Solution for Large Diameter Pipes

- Sewage Flow Meters and Effluent Flow Meters for Wastewater

- Gear Flow Meter Technologies: Oval, Spur, and Helical

Sino-Inst is a professional flowmeter manufacturer and supplier. Sino-Inst offers more than 100 flowmeter products. About 30% of them are electromagnetic flowmeters, and the rest are turbine flowmeters, vortex flowmeters, ultrasonic flowmeters, and mass flowmeters. Differential pressure flowmeters are the most widely used. We offer a variety of flowmeter options, such as free samples and paid samples.

Sino-Inst’s flowmeters serve industrial applications such as: cooling water, industrial gases, corrosive media and brine, chemical processing, mining, wastewater, energy, electronics, laboratories, medical, and many other industries. Sino-Inst sells products through a mature distribution network covering all 50 states in the United States and 30 countries around the world. Flowmeter products are most popular in the domestic market, Southeast Asia, Europe, and the Americas.

If you need to perform water flow measurement, or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)