What is the Turbine Flow Meter K Factor? This has attracted the attention of many people. The coefficient k of the turbine flowmeter is a coefficient of the meter, which will increase with the increase of the flow rate.

Turbine flow meters are usually used to measure some liquids such as water, oil, diesel, etc. There are also many ways to install the turbine flowmeter. Flange, threaded and plug-in types are all available for installation.

Calculation of Turbine Flow Meter K Factor

There are two types of instrument constant k for turbine flowmeters from different manufacturers:

One is k=f/Q, which is the number of vortices generated per unit flow;

Another kind of k=Q/f, that is, the flow rate corresponding to each vortex.

The k value is calibrated with factory water. The sensor measures the number of vortexes in the meter and compares it with the volumetric flow rate measured by the calibration device to obtain the k value.

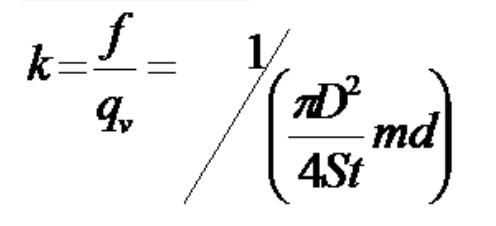

The k value is actually related to the mechanical structure inside the flowmeter measuring tube. Now take k=f/Q as an example, the formula is as follows:

In the formula,

D—-Measuring tube diameter

St —- Strouhal number, constant within a certain range of Reynolds number

d —- characteristic width of vortex generating body

m—The ratio of the arcuate area on both sides of the vortex generating body to the cross-sectional area inside the pipe

Actually, giving you this formula doesn’t have any practical meaning. The values of d and m are difficult to measure accurately. Therefore, it is difficult to obtain an accurate k value by calculation.

The coefficient of the turbine flowmeter can be divided into two sections, namely the linear section and the nonlinear section.

The linear segment is about two-thirds the size of its working segment. Its characteristics are related to the sensor structure size and fluid viscosity.

In the nonlinear section, the characteristics are greatly affected by bearing friction and fluid viscous resistance.

When the flow rate is lower than the lower limit of the flow rate of the sensor, the meter coefficient changes rapidly with the flow rate.

Pressure loss and flow rate are approximately quadratic. When the flow exceeds the upper flow limit, care should be taken to prevent cavitation.

The shapes of the TUF characteristic curves with similar structures are similar, it differs only in the level of systematic error.

The characteristic curve of the turbine flowmeter is verified by the flow verification device, which does not ask the internal fluid mechanism of the sensor at all. The sensor is regarded as a black box, and its conversion coefficient is determined according to the input (flow rate) and output (frequency pulse signal), which is convenient for practical application.

However, it should be noted that this conversion factor (meter factor) is conditional. Its calibration conditions are reference conditions. If the use deviates from this condition coefficient will change, the change situation depends on the sensor type. It depends on the pipeline installation conditions and the physical parameters of the fluid.

The theoretical flow equation of the turbine flowmeter can obtain the motion equation of the impeller according to the momentum moment.

Turbine flow meters are a very important part of energy metering. Widely used in environmental protection, chemical industry, energy and many other fields. Some of our commonly used energy is measured by turbine flowmeters, which play an irreplaceable role in energy management and economic accounting.

Many manufacturers produce turbine flowmeters. Sino-Inst is a company specializing in the production of turbine flowmeters. Over the years, Sino-Inst has been working hard to improve the quality of turbine flow meters. Now that you know the coefficient k of the turbine flowmeter, you should know more about the turbine flowmeter.

Featured Turbine Flow Meters

More Flow Measurement Solutions

Sino-Inst, Manufacturer for turbine flow meters. For example crude oil flow meter, diesel flow meter, gasoline flow meter.

A turbine flow meter is constructed with rotor and blades. Turbine flow meters use the mechanical energy of the fluid to rotate the rotor in the flow stream. Turbine flow meter is the most popular equipment to measure inline flow electronically. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, chemicals, water, cryogenic liquids, air, and industrial gases. Turbine Flow Meters are easy to maintain, durable and versatile.

Sino-Inst’s turbine flow meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

-1.jpg)