Liquid Turbine Flow Meter Specs

| Brand Name | Diameter | Accuracy | Installation | Output | Temp. range | Delivery Time | Warranty | After-sales Service | Package | MOQ |

| Sino-Inst | DN4-DN200 | ±0.1%, ±0.5%, ±0.2%(Optional) | Flange connection DN15-DN200; Screw connection: DN4-DN50; Loose flange connection: DN4-DN200 | Pulse, 4-20mA analog output, RS485 (Modbus-RTU protocol), HART | -20~+150℃(OEM) | 1-3 Work days | 1 Years | Video technical support | Carton packing; export wooden packing | 1 Set |

Flow Range

| Diameter (mm) | 4 | 6 | 10 | 15 | 20 | 25 | 32 | … | 150 | 200 |

| Standard flow range (m3/h) | 0.04~0.25 | 0.1~0.6 | 0.2~1.2 | 0.6~6 | 0.8~8 | 1~10 | 1.5~15 | … | 30~300 | 80~800 |

| Extended flow range (m3/h) | 0.04~0.4 | 0.06~0.6 | 0.15~1.5 | 0.4~8 | 0.45~9 | 0.5~10 | 0.8~15 | … | 15~300 | 40~800 |

| Conventional endurance pressure | 1.6MPa | 1.6MPa | 1.6MPa | 1.6MPa | 1.6MPa | 1.6MPa | 1.6MPa | … | 1.6MPa | 1.6MPa |

| Item | Data |

| Medium | Non-corrosive low velocity liquid without impurity,not suitable for gas/steam |

| Accuracy | ±0.1%,±0.5%,±0.2%(Optional) |

| Flange standard | GB/T 9119-2010, DIN, ANSI, JIS |

| Output | Pulse, 4-20mA analog output, RS485 (Modbus-RTU protocol), HART |

| Diameter and installation | Flange connection DN15-DN200 |

| Screw connection: DN4-DN50 | |

| Loose flange connection: DN4-DN200 | |

| Medium temperature | Default type T1: -20℃~+80℃ (Standard) |

High temp. type T2: -20℃~+120℃ (OEM) | |

High temp. type T3: -20℃~+150℃(OEM) | |

| Operation condition | Operating temperature: -20℃~+60℃ |

| Related humidity: 5%~90% | |

| Atmospheric pressure: 86kPa~106kPa | |

| Ingress protection | IP65 or IP68 |

| Explosion proof | Exia‖CT4 or Exd‖BT6 |

In addition to regular products, we support customization

| SI-3202- | Note | ||||||||

| Diameter | DNXX | DN4~DN200mm | |||||||

| Converter Type | N1 | 24VDC,Pulse output,No display | |||||||

| N2 | 24VDC,Pulse output,No display,EX | ||||||||

| A | 24VDC,4-20mA output,No display,EX | ||||||||

| E1 | Battery power supply,No output,Digital display,EX | ||||||||

| E2 | 24VDC,Pulse and 4-20mA output,RS485,Digital display,EX | ||||||||

| E2+B | 24VDC+battery power supply,Pulse and 4-20mA output,RS485,Digital display,EX | ||||||||

| E3 | 24VDC,Pulse and 0-20mA output,RS485,Digital display,EX | ||||||||

| E3+B | 24VDC+battery power supply,Pulse and 0-20mA output,RS485,Digital display,EX | ||||||||

| E+H | 24VDC,4-20mA output,HART,Digital display,EX | ||||||||

| G5 | 220VAC,Pulse and 4-20mA output,RS485,Digital display,EX | ||||||||

| G6 | 220VAC,Pulse and 0-20mA output,RS485,Digital display,EX | ||||||||

| Accuracy | 10 | ±1.0%R | |||||||

| 5 | ±0.5%R | ||||||||

| Flow Range | S | Standard Range | |||||||

| E | Extended Range | ||||||||

| Body Material | S4 | SS304 | |||||||

| S6 | SS316 | ||||||||

| Explosion-Proof | BT | Exd II BT6 | |||||||

| NA | None | ||||||||

| Connection | THM | External thread,Apply to DN4~DN50mm | |||||||

| THF | Internal thread,Apply to DN4~DN50mm | ||||||||

| WAF | Flange clamp | ||||||||

| DXX | D16:DIN PN16 Flange;D25:DIN PN25 Flange | ||||||||

| AXX | A15:ANSI 150# Flange;A30:ANSI 300# Flange | ||||||||

| JXX | J10:JIS 10K Flange;J20:JIS 20K Flange | ||||||||

| Temperature | T1 | -20~+80℃ | |||||||

| T2 | -20~+120℃ | ||||||||

| T3 | -20~+150℃ | ||||||||

SI-3202 DN50 E2 10 S S4 BT D16 T2

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

① Diameter:DN50

② E2:24VDC,Pulse and 4-20mA output,RS485,Digital display,EX

③ 10:1.0% of rate accuracy

④ S:Standard range 4-40m³/h

⑤ S4:SS304 Body Material

⑥ BT:Exd II BT6

⑦ D16:Flange DIN PN16

⑧ T2:-20~+120℃

Turbine flow meters measure the velocity of liquids,

gases and vapors in pipes, such as hydrocarbons,

chemicals, water, cryogenic liquids, air, and industrial gases.

SI-3202 Liquid Turbine Flow Meter is the best choice for:

-Refined oil, light crude oil, gasoline, light oil, jet fuel, light diesel oil, naphtha, ethylene, etc.

-Lubricating oil, hydraulic oil, etc.

-Water, pure water, distilled water, deionized water, desalinated water, demineralized water, etc.

-Alcohol, benzene, toluene, xylene, butadiene, carbon tetrachloride, methylamine, acrylonitrile, etc.

-Formaldehyde, citric acid, caustic soda, carbon disulfide, etc.

-Milk, coffee, etc.

-High temperature medium such as heat transfer oil and hot kerosene>Methanol/Alcohol

Amis

Thanks for your quick responce. This Insertion type mag flow meter really works well in our wastewater pipes.

Techincal Support

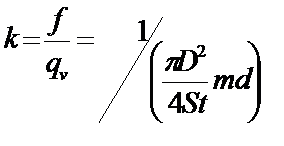

There are two different manufacturers k:

one is k = f / Q, which is the number of vortices generated per unit flow;

the other is k = Q / f, which is the flow corresponding to each vortex.

The k value is calibrated by the factory water.

The number of vortices of the sensor measuring instrument is compared with the volume flow measured by the calibration device to obtain the k value.

The value of k is actually related to the mechanical structure inside the measuring tube of the flow meter.

Take k = f / Q as an example, the formula is as follows:

Where

D —- Measuring tube diameter

St —- Strauhal number, constant in a certain range of Reynolds number

d —- characteristic width of vortex generator

m–the ratio of the arcuate area on both sides of the vortex generator to the cross-sectional area inside the pipe

The values of d and m are difficult to measure accurately, so it is difficult to obtain accurate k values by calculation.

Turbine Meter Advantages | Turbine Meter Disadvantages |

Wide flow rangeability including low flow rates | Requires constant backpressure to prevent cavitation |

Turndown ratio is up to 35:1 | Accuracy adversely affected by bubbles in liquids |

Good level of accuracy at an economic price | Turbine meters can be used with clean liquids and gases only |

Simple, durable construction | Not applicable for measuring corrosive fluids |

Easy to install and maintain | Requires a turbulent flow profile (consistent fluid velocity across the pipe diameter) for accuracy |

Flexible connection to flow instruments for flow control | Sensitive to changes in fluid viscosity |

Wide variety of process connections | Require a straight run of pipe before and after the turbine meter to allow swirl patterns in the flow stream to dissipate |

Turbine meters can operate over a wide range of temperatures and pressures | |

Low pressure drop across the turbine | May not function properly with high viscosity fluids where the flow profile is laminar |

Provides a convenient signal output |

Turbine type flow meter

Turbine type flow meter is one type of mechanical flow meters. Turbine flow meter use the mechanical energy of the liquid to rotate a rotor in the flow stream. Turbine flow meters measure the velocity of a variety of liquids (oil, water), gases (natural gas) and vapors. All types turbine flow meters, like: flange, sanitary flow meter, insertion, threaded connections etc .

Sanitary Flow Meter

Sanitary Flow Meter, also called the tri-clamp flow meter. Sanitary Flow Meters have stainless steel bodies and come standard with Tri-Clover fittings. Sanitary flow meter meets the requirements of the food, and beverage company industries. Sino-Inst’s magnetic flowmeter and turbine flow meters is available in a sanitary version. And allows for use with Output Modules, Sensors and Remote Transmitters.

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes. Magnetic flow meters can be Remote type, compact type, insertion type. And ultrasonic flow meters are another choice, if you can not change your pipes. Both ultrasonic flow meters and magmeters are inline flow meters. Sino-Inst offers ultrasonic and magnetic flow meters, which offer the highest flow meter accuracy and reliability, as well as long-term stability and a low cost-of-ownership.

Water Flow Meter Types

Water Flow Meters are flow meters measure and show the flow rate of water flow. Water flow measurement is important for inductrial applications, like the wastewater treatment. In principle, water flow meter types are: Electromagnetic (magnetic), Turbine, Ultrasonic, and DP. Coriolis and Oval Gear flow meters can also work for water flow measurement. These water flow meters, optional with digital display, battery, analog or pulse output. Material can be 316 stainless steel or special material.

-1.jpg)