In the realm of industrial flow measurement, mechanical flow meters stand as a testament to engineering precision and reliability. These devices have played a pivotal role in gauging the flow of various liquids, notably water and diesel.

The mechanical flow meter, in its essence, operates on the working principle of positive displacement. Here, a defined volume of liquid, be it fuel, oil, or water, is transported between sensors. Mechanical flow meters designed specifically for oil flow measurement or diesel often incorporate parts like the oval gear flow, providing superior accuracy.

What is a Mechanical Flow Meter?

A mechanical flow meter is a precise instrument designed to measure the total flow of a liquid. It utilizes mechanical components, like gears, rotors, impellers, or turbines, which move in response to the fluid flowing through them.

One notable advantage of mechanical flow meters is their independence from external power sources; they function solely based on the movement of the liquid. For effective operation, it’s essential for the flow to remain consistent, ensuring the impeller or rotor maintains its motion.

Introduced in the 20th century, mechanical flow meters have become a staple in flow measurement. Their enduring popularity underscores their reliability and efficiency, making them a trusted choice even in today’s advanced technological era.

Types of Mechanical Flow Meters

Mechanical flow meters have evolved over time, leading to the development of several distinct types. Each type is designed with specific applications in mind, ensuring accurate flow measurements across varied conditions and mediums. Let’s delve into the prominent variants:

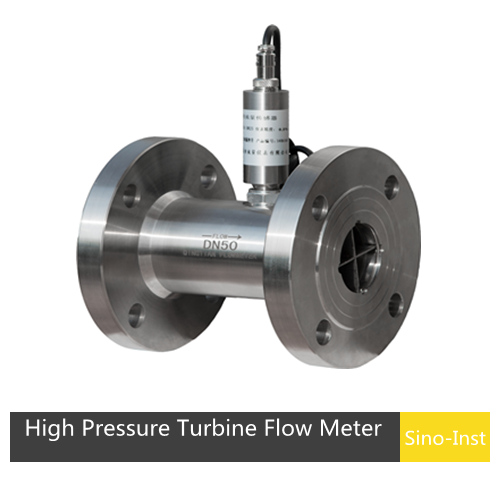

Turbine Flow Meters:

This type employs a turbine or a rotor placed in the flow’s path. As the liquid moves, it drives the turbine, with the speed of rotation corresponding to the flow rate. They’re commonly used for applications involving water, chemicals, and fuels.

Positive Displacement Flow Meters:

Operating on a unique principle, these meters have chambers that fill and empty with the liquid. The number of times these chambers fill and then empty provides a measure of the total flow. They excel in measuring viscous liquids, such as oils and syrups.

Rotameter Flow Meters:

Distinguished by their tapered vertical tubes and float mechanism, Rotameters provide readings based on the float’s position in the tube. As the fluid flows upwards, the float rises, and its position provides a direct indication of the flow rate. They’re versatile and can handle both gases and liquids.

In conclusion, the world of mechanical flow meters offers a range of options tailored to specific needs. Whether you’re measuring the flow of water in an industrial setting or gauging gas flow in a laboratory, there’s a mechanical flow meter designed to serve the purpose with precision.

Key Advantages of Mechanical Flow Meters Over Digital Ones

In the age of digitalization, where technology continually evolves, mechanical flow meters have retained their significance in numerous industries. But why do these traditional devices still hold ground when pitted against their advanced digital counterparts? Here are some key advantages:

No Power Dependency:

Mechanical flow meters operate without the need for an external power source. This autonomy ensures they remain functional even in remote areas or during power outages.

Durability and Longevity:

Crafted from robust materials and designed to withstand various conditions, mechanical flow meters offer impressive durability. Their longevity makes them a one-time investment for many applications.

Simple Operation:

With fewer electronic components, mechanical flow meters are straightforward in their operation. This simplicity reduces the chances of errors stemming from electronic malfunctions.

Cost-Effective:

Typically, mechanical meters come at a lower initial cost compared to their digital counterparts. When combined with their durability, they offer a cost-effective solution over time.

Wider Application Scope:

Certain industries and applications, especially those dealing with high-viscosity liquids, find mechanical meters more suitable than digital ones.

Tried and Tested:

Mechanical flow meters have been around for a significant period. Their historical use across industries has established them as reliable and efficient tools, instilling confidence in their readings.

Minimal Maintenance:

With fewer electronic parts, mechanical flow meters usually demand less frequent maintenance, ensuring consistent operations without frequent interruptions.

While digital flow meters bring modern conveniences and features, mechanical flow meters boast a set of advantages that make them indispensable in many scenarios. Their simplicity, reliability, and cost-effectiveness explain their enduring relevance in today’s industrial landscape.

Common Mechanical Flow Meters Applications

Mechanical flow meters have carved a niche for themselves across various industries due to their reliability and versatility. Let’s delve into some common applications and industries that heavily rely on these devices:

- Oil and Gas: Mechanical meters are paramount in this sector, especially when monitoring the flow of crude oil, gasoline, and diesel. Their durability under high pressures and ability to measure viscous fluids make them an industry favorite.

- Water Treatment: Ensuring the right volume of water flows through treatment plants, mechanical flow meters offer accurate readings, aiding in both purification processes and wastewater management.

- Agriculture: For tasks like irrigation where the volume of water needs to be controlled, these meters come in handy, providing farmers with precise flow rates.

- Food and Beverage: When processing beverages and liquid foods, consistent flow rates are crucial. Mechanical meters help ensure the right consistency, from juice production to dairy operations.

- Chemical Industries: From monitoring the flow of raw materials to the final product, these meters are vital in ensuring accurate measurements, a critical factor in maintaining product quality.

- Pharmaceuticals: Ensuring the correct flow rates in drug production can be a matter of health and safety. Mechanical meters provide that assurance in many pharmaceutical processes.

- HVAC: In heating, ventilation, and air conditioning systems, maintaining the right flow of coolants and other fluids is essential. Mechanical flow meters assist in keeping these systems running efficiently.

In essence, the versatility and reliability of mechanical flow meters make them an integral component in various industries, ensuring operations run smoothly and efficiently.

Mechanical Water Flow Meter

A mechanical water flow meter is a trusty device designed specifically to measure the flow of water. The simplest example is the water meter we use at home.

Imagine a tool that’s like a watchful guardian, keeping tabs on how much water is moving through a system! This meter uses moving parts, such as turbines or gears, which turn as water flows over them. Just like how a windmill spins in the breeze, these parts move with the flow of water. The faster the water moves, the quicker these components rotate. This movement is then translated into a measurement, often displayed as a total amount of water that has passed through.

From household plumbing to big industrial plants, these meters play a crucial role in ensuring we know just how much water is on the move. Simple, efficient, and reliable – that’s the mechanical water flow meter for you!

Mechanical Flow Meter for Diesel

Commonly used diesel flow meters include oval gear flow meters, turbine flow meters, etc. Among them, oval gear flow meters account for a large part because they are mechanical.

Mechanical oval gear flow meters measure diesel, with the advantages of large range, high accuracy, small pressure loss, strong viscosity adaptability, can measure high temperature and high viscosity liquids (diesel), convenient calibration, installation suggestions, etc.

Mechanical diesel flow meters suitable for most fuels, including diesel, biodiesel, kerosene, gasoline, engine oil, DEF, heating oil, grease and certain chemicals. Mechanical diesel flow meters are available in a variety of sizes, ranging from 1/2 inch to 8 inches.

Advantages of Mechanical Flow Meter for measuring diesel:

- Easy to install. No straight pipe section is required before and after the flow meter. Even if the flow meter is close to valves, elbows, shrinkage, and expansion, there is no need to add straight pipe sections.

- No need to connect to electricity. There is no flammable and explosive hidden dangers.

- High measurement accuracy: 0.2 and 0.5;

- Simple, firm and reliable structure;

FAQ

More Featured Water Flow Meters:

More Flow Measurement Solutions

Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

Volumetric Flow Meters: Comprehensive Guide and Product List

Choosing the Right Inline Water Flow Meter

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

Industrial Inline Flow Meters | Selection List

High-Performance Marine Fuel Flow Meters | Save Your Costs!

In the ever-evolving world of flow measurement, the mechanical flow meter stands as a testament to both simplicity and efficiency. Despite the rise of digital alternatives, these mechanical marvels remain relevant, trusted by industries worldwide. They’ve withstood the test of time, continuously proving their worth in accuracy and reliability.

Here at Sino-Inst, we pride ourselves on our rich history and expertise in the world of flow meters. As experienced manufacturers and suppliers, we understand the intricate needs of diverse industries. We’re not just here to provide tools; we’re here to offer solutions.

Looking for a tailor-made mechanical flow meter for your specific needs? Let us craft the perfect solution for you.

-1.jpg)