Where should Magnetic Flow Meter Troubleshooting start?

As a kind of industrial electronic sensor equipment, electromagnetic flowmeter will inevitably have some equipment failure problems in the process of use. So when the electromagnetic flowmeter fails, we usually analyze which component has the problem. Then find a solution to the problem corresponding to the problem. Below, Sino-Inst will explain to you the common faults of electromagnetic flowmeters in daily life, and then how to deal with the faults.

Magnetic Flow Meter Troubleshooting Checklist

Phenomenon 1: Large flow fluctuations

| Influencing factors | Approach |

| 1. The medium contains excessive air bubbles or particles | Changed to vertical installation |

| 2. The conductivity of the medium is uneven or close to the middle value | Change the installation location or reselect the model |

| 3. Split line failure | Check the split cable and choose a cable with good shielding |

| 4. Sensor insulation drops | Return to factory for repair |

| 5. Inverter interference | Change the installation location or return to the factory for repair |

| 6. The electrode is covered with dirt or corroded | Clean and inspect electrodes |

| 7. With pulsating flow | Increase damping time or fake pipe damper |

Phenomenon 2: The flow rate display is too small

| Influencing factors | Approach |

| 8. The motor has fouling | Descaling |

| 9. The excitation part of the converter is faulty | replace converter |

| 10. The inside of the watch body is damp | Dry out or return to factory for repair |

| 11. Pipeline blockage | Check and clean the pipes to keep them clear |

Phenomenon 3: The flow display is too large

| Influencing factors | Approach |

| 12. There is a small amount of air bubbles in the pipeline | Add exhaust |

| 13. Scaling in the pipeline has conductive substances | check pipes |

Phenomenon 4: No flow display (instantaneous flow is zero)

| Influencing factors | Approach |

| 14. Meter setting reverse | Check gauge settings and correct |

| 15. The flow rate is not enough to the tube, the measured medium is not filled to the electrode, and the empty tube alarm | Change the installation location |

| 16. The electrode is covered by an insulating medium | Clean and inspect electrodes |

Phenomenon 5: The zero point is unstable

| Influencing factors | Approach |

| 17. The medium is not full of pipe | Set the air traffic control alarm and set the air traffic control threshold reasonably |

| 18. The valve is not closed | Check the valve and close it |

| 19. The pipeline vibrates greatly | fixed pipe |

| 20. External magnetic field interference | Ground the flowmeter well |

| 21. Severe fouling of electrodes | cleaning electrode |

| 22. After cleaning the electrode, the electrode oxide film is destroyed | It needs to be filled with medium to soak the electrode for 24~48 hours |

Phenomenon 6: Converter black screen, no display

| Influencing factors | Approach |

| 23. Power problem or lightning strike | Install power protection or lightning arrester |

| 24. Problems with the converter itself | replace converter |

| 25. High temperature or direct sunlight LCD | Improve the installation environment |

| 26. The fuse of the converter is burned out | replacement insurance |

| 27. Liquid crystal damage | Replace the LCD panel |

Phenomenon 7: No flow output

| Influencing factors | Approach |

| 28. Power failure | Check whether there is a fault in the power supply part, test whether the power supply voltage is normal; test whether the fuse is on or off; |

| 29. Check whether the sensor arrow is consistent with the fluid flow direction | If inconsistent, change the installation direction of the sensor; |

| 30. No current output: | Is there DC current at the IOUT and COMM terminals of the meter head after removing the load? |

| 31. No pulse output: | After removing the load, whether there is a direct voltage between the POUT and COMM terminals of the meter head; |

| 32. 485 no output: | (1) Check whether the parameter “communication address” in the header is correct; (2) Check whether the data address in the communication protocol is correct; (3) Use the 485 test software provided by the manufacturer to test whether it is normal; |

Featured Magnetic Flow Meters

Learn More About Magnetic Flow Meters

If you cannot find an answer to your question in our Magnetic Flow Meter Troubleshooting, you can always contact us and we will be with you shortly.

More Flow Measurement Solutions

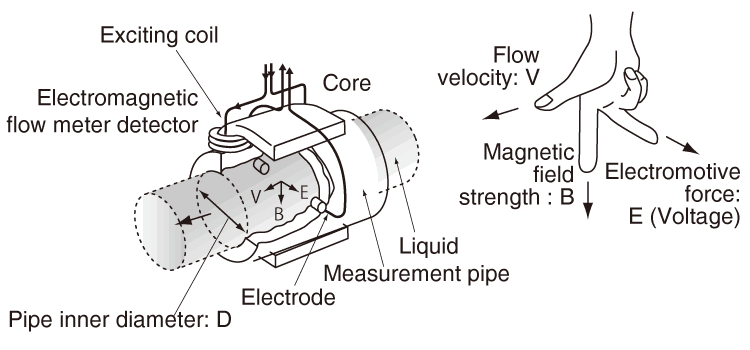

Electromagnetic flowmeters are suitable for measuring the volume flow of conductive liquids in closed pipelines, such as clean water, sewage, various acid-base salt solutions, etc.

The fluid that uses electromagnetic flowmeter to measure flow must be conductive. Therefore, non-conductive gases, steam, oil, acrylic copper and other substances cannot use electromagnetic flowmeter to measure flow.

Magnetic Flow Meter Troubleshooting always appears very headache! The causes of Magnetic Flow Meter Troubleshooting are various. Some are caused by the flowmeter itself, some are man-made, and some are caused by on-site reasons.

If you encounter the above faults in the process of using the electromagnetic flowmeter, you can gradually eliminate and solve them according to the methods given above. If you can’t solve it, it may be because the working conditions on site are too complicated. The electromagnetic field strength is too high. Pay attention to the grounding of the instrument, and you can also contact Sino-Inst to provide technical assistance.

-1.jpg)