Pressure Transducer converts physical pressure into a readable signal. Pressure Transducer Troubleshooting can be a real challenge. Diagnosing field problems often requires skill and knowledge, especially when dealing with complex systems. In this guide, we’ll take a closer look at effective ways to test and maintain pressure sensors, ensuring you have the expertise to handle these challenges.

Understanding Pressure Transducers

Pressure transmitter is a very important instrument in the automation control system. In engineering applications, pressure transmitters use pressure measuring components to convert pressure parameters of gas, liquid and other media into pneumatic signals or electric signals for control and long-distance transmission. This enables a series of functions such as recording, alarming, and adjustment.

According to different classification methods, Pressure Transducer can be divided into different types:

- Working principle

According to the working principle, pressure transmitters can be divided into capacitive, piezoresistive, piezoelectric, strain gauge and single crystal silicon resonant type. Among them, the single crystal silicon resonant pressure transmitter utilizes the excellent elastic properties of single crystal silicon. The sensor output is frequency output, with strong anti-interference ability and good stability. Without signal processing, it is a more convenient and excellent transmitter. - According to the measurement pressure type

According to the type of pressure measurement, there are mainly gauge pressure, absolute pressure, differential pressure, etc.

Gauge pressure is a pressure measurement method based on standard atmospheric pressure;

Absolute pressure is based on the absolute zero point of pressure;

Differential pressure is calculated as the pressure difference between two different measuring points. - According to the output mode

According to the output mode, it can be divided into current, voltage, digital signal and other output modes.

Featured Pressure Transducers

Multimeters in Pressure Transducer Troubleshooting

What is a Multimeter?

A multimeter is a multi-functional, multi-range measuring instrument that can measure DC current, DC voltage, AC current, AC voltage, resistance, diode, transistor, capacitance, etc.

A multimeter is like an electrician’s detective tool. A multimeter is very useful when troubleshooting pressure sensors. It helps diagnose problems by reading the sensor’s electrical signals, telling us whether it’s working properly. Whether it’s a simple home repair or complex industrial machinery, a multimeter is an essential tool in any tool kit.

How to Test a Sensor with a Multimeter?

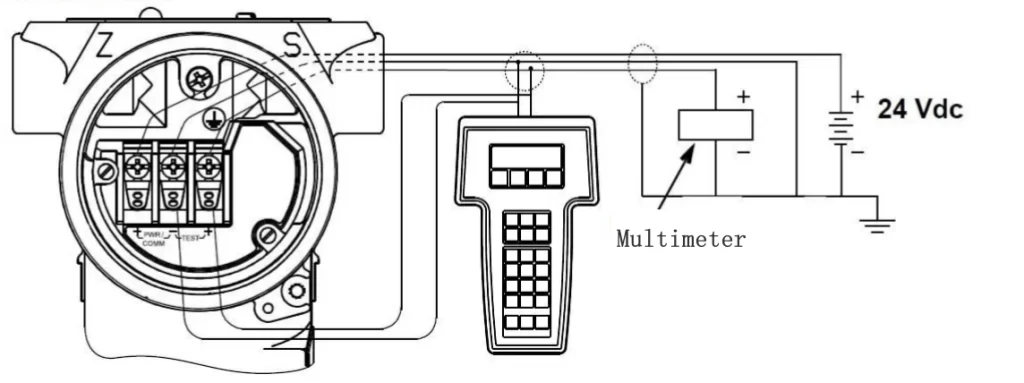

To test a pressure sensor using a multimeter, follow these steps:

- Connect the sensor: Connect the pressure sensor to the multimeter.

- Application Voltage: Use the appropriate voltage to power the sensor. This is called the “excitation voltage”.

- Measure Output: For sensors with a current output (such as 4-20mA), measure the current. For voltage output sensors, the voltage level is measured.

- Compare to Specifications: Check readings against manufacturer’s specifications. Deviations indicate a malfunction.

- Interpret the results: Consistent readings within the specified range indicate that the sensor is functioning properly, while differences indicate a potential problem.

Remember, safety first! Always make sure to follow proper protocol when handling electrical equipment.

How to check a pressure transducer?

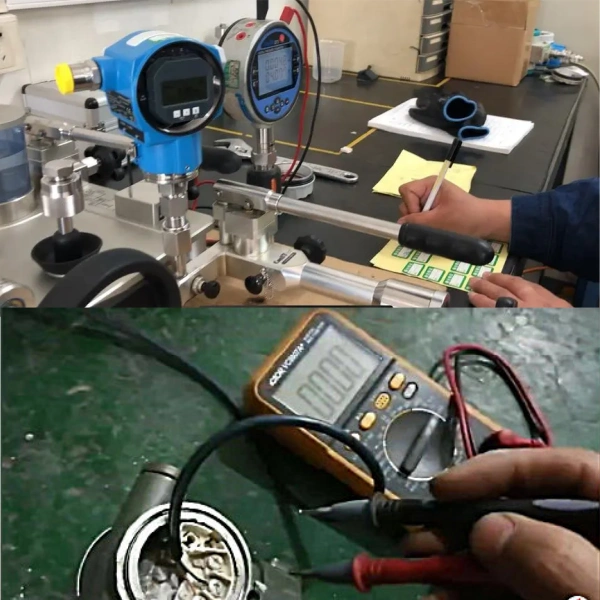

It is critical to test the pressure transmitter before installation. If you use a faulty pressure transmitter, you are more likely to obtain inaccurate pressure data, which can lead to adverse results.

Also, pressure transmitters should be tested regularly to ensure they are functioning properly and within specifications.

How to Test a 2-Wire Current Pressure Sensor

Connect the sensor’s positive terminal to the power supply’s positive.

Link the sensor’s negative terminal to the multimeter’s positive lead.

Connect the multimeter’s negative lead to the power supply’s negative terminal.

Manufacturer’s data sheets often specify precise values corresponding to various pressure measurements. Check that the current reading is within the 4-20mA range, as per the manufacturer’s specifications.

How to Test a 3-Wire Current Pressure Sensor

Attach the power supply’s positive to the sensor’s positive terminal.

Connect the sensor’s negative terminal to the power supply’s negative.

Link the multimeter’s positive lead to the sensor’s current output terminal.

Ensure the current reading falls within the 4-20mA range.

How to Test a 3-Wire Voltage Pressure Transducer

Connect the power supply’s positive and negative terminals to the respective terminals of the sensor.

Link the multimeter’s positive and negative leads to the sensor’s voltage output terminals.

Verify that the voltage reading matches the manufacturer’s specified range.

How to Test a 4-Wire Voltage Pressure Transducer

Attach the power supply’s positive and negative terminals to the sensor’s corresponding terminals.

Connect the multimeter’s positive and negative leads to the sensor’s voltage output terminals.

Check that the voltage reading aligns with the manufacturer’s specifications.

more on pressure sensor technology

Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

Steam Pressure Sensor/transducer for Industrial Steam Measurement

How to Choose the Right Oil Pressure Transmitter for Your Application

Electromagnetic High Pressure Flowmeter | 0.6MPa-1.6MPa-6.3MPa-16MPa-25MPa-35MPa-42MPa

Gauge Pressure vs Absolute Pressure | Differences and Relationships

Industrial Water Pressure Sensors | Selection Guide

How to calibrate a pressure transmitter? How often?

10 Point Guide! Selection of Pressure Transmitters

Pressure Transducer Troubleshooting is a very important thing before and during use of the pressure transmitter. Before taking measurements, you need to choose a suitable multimeter. Generally, you need to choose a digital multimeter with DC current and voltage measurement functions. In addition, it is recommended to choose products with automatic measurement range switching function, higher protection level and higher measurement accuracy.

We at Sino-Inst are professional Pressure Transducer manufacturers. Our Pressure Transducers are widely used in pressure measurement of liquids, steam, and other gases. And supports 4-20mA, RS485, HART and other signals. There are also special customizations such as special high temperature, extremely low temperature, ultra-high pressure, etc.

If you have any questions about Pressure Transducer Troubleshooting, please feel free to contact our sales engineers!

-1.jpg)