Oil pressure transmitters are devices that measure the pressure of oil in pipes and engines. They play a vital role in keeping machines running smoothly by detecting any changes in oil pressure. A well-chosen oil pressure transmitter helps prevent damage to equipment, reduces downtime, and ensures safety. Picking the right transmitter is crucial, and this guide will help you understand and choose the best oil pressure transmitter for your specific needs.

What Do Oil Pressure Transmitters Do?

Oil pressure transmitters are devices that keep an eye on the force of oil in machines, like engines or pipes.

Oil pressure transmitters make sure everything is working well and safely. When the pressure of the oil changes, these transmitters can sense it and send an electrical signal. Like 4-20mA, 0-10V.

This signal can be read and monitored, allowing people to know if there’s a problem or if the machine is running smoothly.

So, oil pressure transmitters play an important part in keeping machines in good shape and preventing damage.

Common types of oil pressure transmitters

There are many types of oil pressure transmitters. We only discuss the commonly used of the 3 here.

Capacitive: Capacitive transmitters measure oil pressure by detecting changes in electrical capacity. They have two plates with a gap between them. When pressure changes, the gap gets smaller or bigger, which affects the capacity.

Capacitive transmitters are good at handling high temperatures and don’t cost much, making them popular in many applications.

Diffused Silicon: These transmitters use a special material called diffused silicon to measure oil pressure. The silicon changes its electrical resistance when pressure is applied.

Diffused silicon transmitters offer high accuracy and stability, and they can handle a wide range of pressures.

Single Crystal Silicon: Similar to diffused silicon transmitters, single crystal silicon transmitters also measure pressure by detecting changes in electrical resistance. However, they use a single crystal of silicon, which offers even better accuracy and stability.

These transmitters are great for very precise measurements but can be more expensive than other types.

Each type of oil pressure transmitter has its own advantages, so it’s essential to choose the one that works best for your needs.

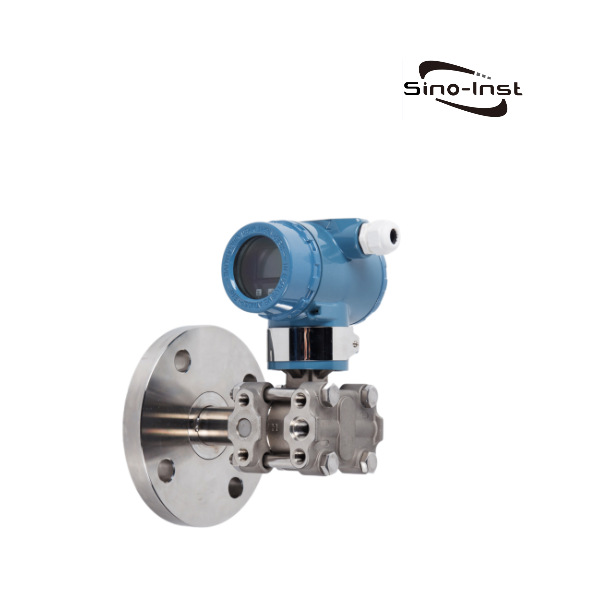

Featured Oil Pressure Sensors

Featured Oil Pressure Transmitters and Transducers

How to Choose the Right Oil Pressure Transmitter for Your Application

Here are some simple steps to help you pick the right oil pressure transmitter:

- Identify your needs: Think about what you need the transmitter for. Consider the pressure range, temperature, and environment where it will be used.

- Learn about types: Research the different types of transmitters, like capacitive, diffused silicon, and single crystal silicon. Understand their benefits and drawbacks.

- Match your needs: Choose the transmitter type that best fits your needs, based on its strengths and weaknesses.

- Consider materials: Pick a transmitter with materials that can handle the conditions it will face, such as high temperatures or corrosive environments.

- Look at the output: Make sure the electrical output from the transmitter works with your control system or software. Like 4-20mA, 0-5V, 0-10V, RS485.

- Check connections: Ensure the mechanical and electrical connections are compatible with your setup. Like M20*1.5;

- Think about safety: Keep in mind any safety certifications or requirements that apply to your application.

- Compare costs: Consider the price of the transmitter, as well as long-term costs like maintenance or replacement.

- Find a supplier: Look for a reputable manufacturer or supplier that offers good customer support and warranty options.

By following these steps, you can find the perfect oil pressure transmitter for your application.

Frequently

Asked

Questions

More Pressure Measurement Solultions

Gauge Pressure vs Absolute Pressure | Differences and Relationships

Industrial Water Pressure Sensors | Selection Guide

How to calibrate a pressure transmitter? How often?

10 Point Guide! Selection of Pressure Transmitters

Choosing the right oil pressure transmitter is crucial for keeping your machines running safely and smoothly. By understanding the different types of transmitters, identifying your needs, and considering factors like materials, connections, and costs, you can find the perfect transmitter for your application.

If you need help selecting an oil pressure transmitter, consider reaching out to Sino-Inst, a professional manufacturer with years of experience in the industry.

We offer high-quality oil pressure transmitters and excellent customer support to help you make the best choice. Visit Sino-Inst’s website or contact them today to find the ideal transmitter for your needs.

-1.jpg)