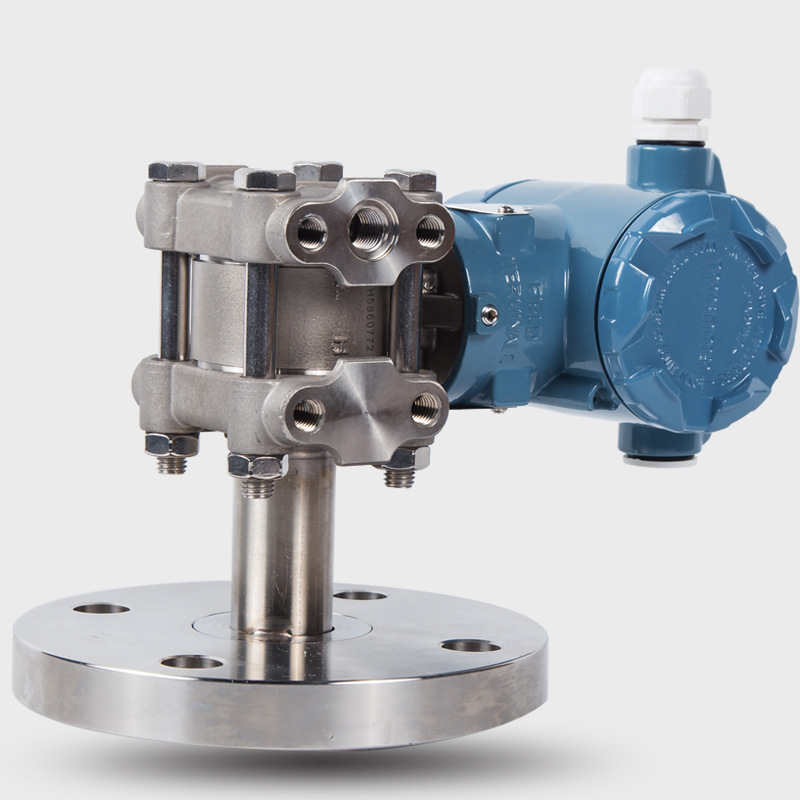

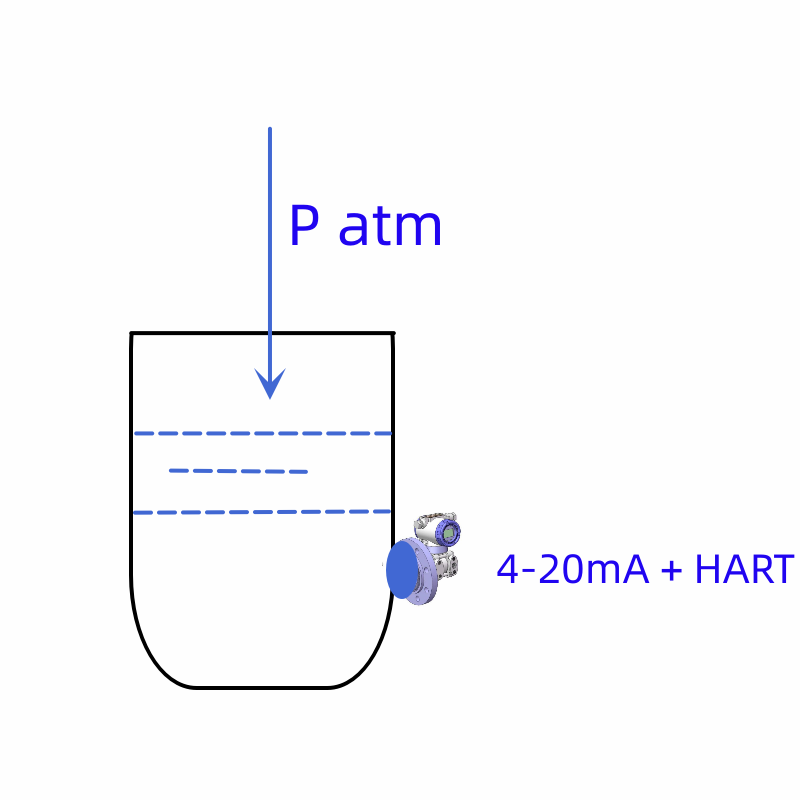

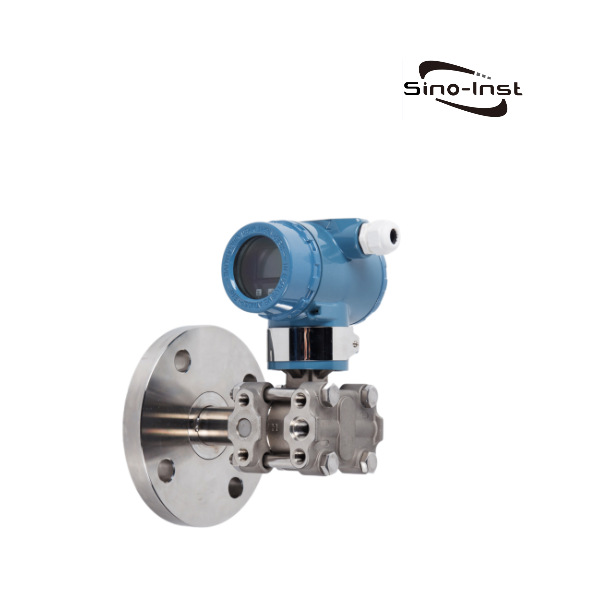

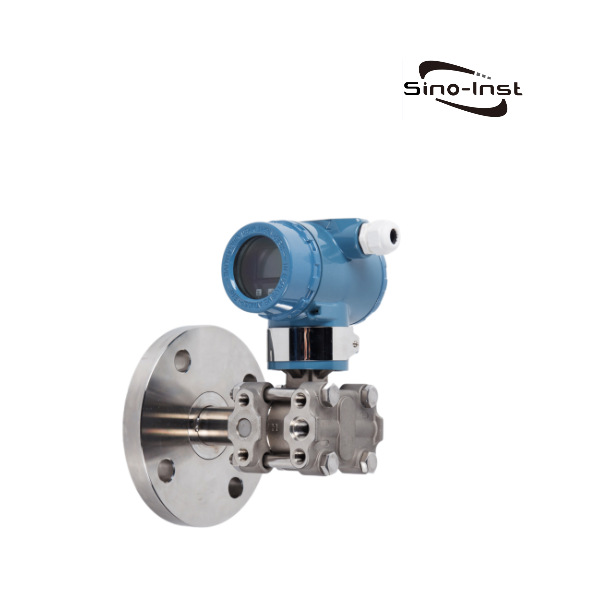

Pressure level transmitters designed to ensure accurate measurement of liquid levels in a variety of tank environments. The Rosemount 3051L Level Transmitter manufactured by Emerson has become the ideal instrument for open or closed tank applications. Our SI-3151LT Pressure Level Transmitter was built using this as a prototype.

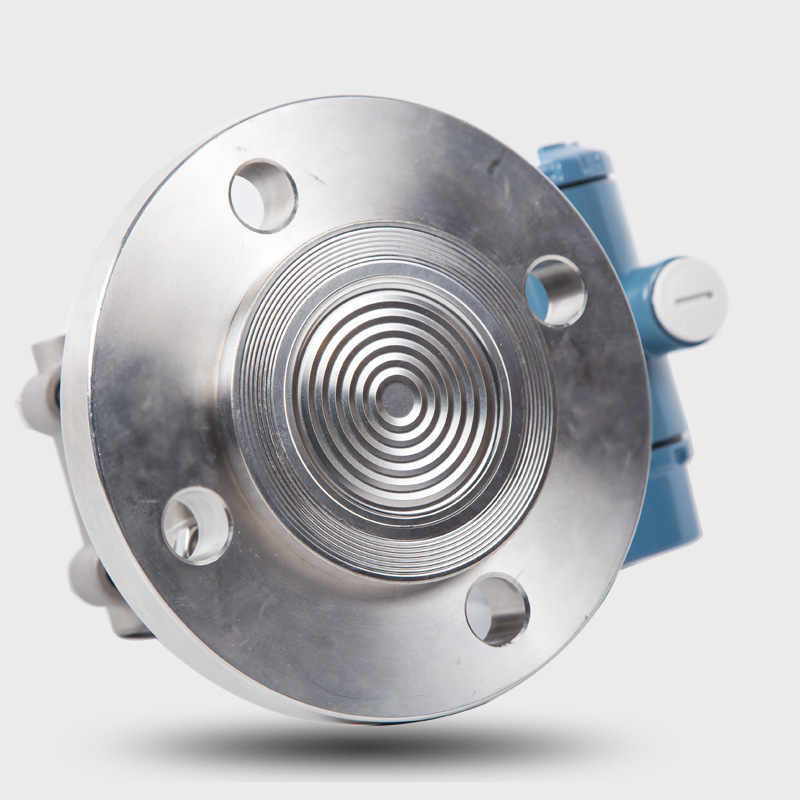

Features a flange-mounted diaphragm designed to easily handle varying hydrostatic pressures and temperature changes. Whether used in vessels or open tanks, our pressure level transmitters deliver unmatched reliability.

Features of SI-3151LT Pressure Level Transmitter

The single flange liquid level gauge is an extension and development of pressure transmitter technology. According to the principle that the pressure generated by liquids with different specific gravity at different heights is linearly related, it realizes the volume, liquid height, Accurate measurement and transfer of weight.

- The “dynamic profile” remote transmission diaphragm structure is adopted, the diaphragm will not be damaged after overloading, and the accuracy will not change after long-term work.

- The filling system with full fusion welding and rigid sealing structure is used to eliminate the occurrence of oil leakage.

- The novel design of the capillary combined parts ensures the reliable protection of the capillary and is not easy to break when used on site.

- Remote transmission devices with various varieties, shapes and sizes, as well as a variety of filling fluids can meet the measurement needs of various occasions.

- Various products for special needs can be provided, including remote pressure transmitters for high temperature, high vacuum, fast response and unequal length capillary (length ≤ 3 meters).

- Easy to adjust: The two potentiometers of zero position and range can move the zero point or change the range arbitrarily within the effective range of liquid level detection. The two adjustments do not affect each other.

- Wide range of uses; suitable for liquid level measurement of high temperature, high pressure, strong corrosion and other media.

- The measuring range is large and not limited by the height of the storage tank.

- With intrinsically safe explosion-proof and isolated explosion-proof capabilities, it can be used in various dangerous places.

- With anti-blocking design, it can realize the measurement of the liquid level of paste medium.

- Exquisite and unique zero point, full scale, and non-linear compensation. Guarantee the accuracy of the instrument within the range of operating conditions and good long-term stability.

SI-3151LT Pressure Level Transmitter Specifications

| Measuring range | 4.0Kpa-10.0MPa |

| Turndown ratio | 50:01:00 |

| Power supply | 10.5V~45V d.c. (Intrinsically safe safety barrier power supply≤30Vd.c.) |

| Output | 4mA~20mA d.c. and HART communication |

| Ambient temperature | -40℃~85℃ |

| Medium temperature | -40~304℃ (customized according to actual temperature) |

| Accuracy | 0.5% (capacitive), 0.2 (monocrystalline silicon) |

| Temperature drift | ≤(0.08r+0.1)﹪(-10℃~60℃) ≤(0.1+0.15) ﹪/10℃(-40℃~-10℃;60-85℃) |

| Long-term drift | ≤0.15r﹪/5 years |

| Enclosure rating | IP67 |

| Explosion-proof grade | EX iaⅡCT6 or EX dⅡCT6 |

| Anti-corrosion | Select the corresponding measuring part material according to different media |

| Measurement object | Viscous, warm liquid |

| Installation method | Flange flat membrane type, flange plug-in type |

| Diaphragm material | 316L, Hastelloy C-276, Monel, Tantalum, Gold Plated, 316L+PTFE |

| Flange material | 304, 316L |

Pressure Level Transmitter-Flange Mounting Applications

The single-flange liquid level transmitter can measure the liquid level of various open containers and tanks. It is suitable for the measurement of high viscosity medium, suspension liquid and easy crystallization medium. Wetted diaphragm materials include 316L, Hastelloy C-276, Monel, tantalum, gold-plated, 316L+PTFE and other corrosion-resistant materials.

Mainly applicable to the following scenarios:

- Viscous medium at high temperature;

- Medium that is easy to crystallize;

- Sedimentary media with solid particles or suspended matter;

- Strong corrosive or highly toxic medium;

- It can eliminate the occurrence of the leakage of the pressure guiding tube and pollute the surrounding environment. It can avoid the tedious work of frequently replenishing the isolation fluid due to the instability of the measurement signal when the isolation fluid is used;

- Continuous and accurate measurement of interface and density;

- The remote transmission device can avoid the mixing of different instantaneous media, so that the measurement results can truly reflect the actual situation of the process change;

- Occasions with high requirements for sanitation and cleanliness;

- For example, in the production of food, beverage and pharmaceutical industries, it is not only required that the part of the transmitter in contact with the medium meets the hygienic standards, but also it should be easy to wash to prevent cross-contamination of different batches of media.

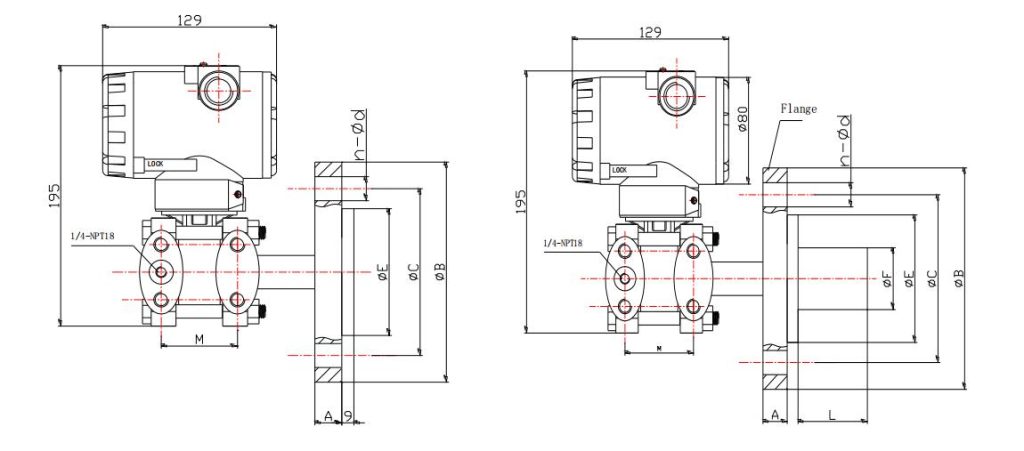

SI-3151LT Flange Specification Sheet

Common flange flush type specifications are as follows:

DN50(2 “) flange dimension specification sheet

| Flange standard | B | C | E | A | Number of bolts n | Bolt aperture |

| 150LB | 150 | 120 | 95 | 19 | 4 | 18 |

| 300LB | 165 | 127 | 95 | 20 | 8 | 18 |

| 600LB | 165 | 127 | 95 | 32 | 8 | 18 |

| 900LB | 215 | 165 | 95 | 45 | 8 | 26 |

| PN1.6/1.0 | 165 | 125 | 95 | 18 | 4 | 18 |

| PN2.5/4.0 | 165 | 125 | 95 | 20 | 4 | 18 |

| PN6.4 | 180 | 135 | 95 | 26 | 4 | 22 |

DN80(3 “) flange dimension specification sheet

| Flange standard | B | C | E | A | Number of bolts n | Bolt aperture |

| 150LB | 190 | 152 | 124 | 20 | 4 | 18 |

| 300LB | 210 | 168 | 124 | 25 | 8 | 22 |

| 600LB | 210 | 168 | 124 | 38 | 8 | 22 |

| 900LB | 240 | 191 | 124 | 54 | 8 | 26 |

| PN1.6/1.0 | 200 | 160 | 124 | 20 | 8 | 18 |

| PN2.5/4.0 | 200 | 160 | 124 | 24 | 8 | 18 |

| PN6.4 | 215 | 170 | 124 | 28 | 8 | 22 |

DN100 (4 “) flange dimension specification sheet

| Flange standard | B | C | E | A | Number of bolts n | Bolt aperture |

| 150LB | 230 | 190 | 155 | 24 | 4 | 18 |

| 300LB | 255 | 200 | 155 | 32 | 8 | 22 |

| 600LB | 275 | 215 | 155 | 45 | 8 | 26 |

| 900LB | 290 | 235 | 155 | 50 | 8 | 33 |

| PN1.6/1.0 | 200 | 180 | 155 | 20 | 8 | 18 |

| PN2.5/4.0 | 200 | 190 | 155 | 24 | 8 | 22 |

| PN6.4 | 215 | 200 | 155 | 28 | 8 | 26 |

DN40 Flange size specification sheet

| Flange standard | B | C | E | A | Number of bolts n | Bolt aperture |

| PN1.6/2.5 | 150 | 110 | 84 | 18 | 4 | 18 |

| PN2.5/4.0 | 150 | 110 | 84 | 18 | 4 | 18 |

| PN6.4 | 170 | 125 | 89 | 26 | 4 | 22 |

Common flange insertion barrel specifications are as follows:

DN50(2 “) flange size specification sheet

| Flange standard | B | C | E | F | A | Number of bolts n | Bolt aperture |

| 150LB | 150 | 120 | 95 | 48 | 19 | 4 | 18 |

| 300LB | 165 | 127 | 95 | 48 | 20 | 8 | 18 |

| 600LB | 165 | 127 | 95 | 48 | 32 | 8 | 18 |

| 900LB | 215 | 165 | 95 | 48 | 45 | 8 | 26 |

| PN1.6/1.0 | 165 | 125 | 95 | 48 | 18 | 4 | 18 |

| PN2.5/4.0 | 165 | 125 | 95 | 48 | 20 | 4 | 18 |

| PN6.4 | 180 | 135 | 95 | 48 | 26 | 4 | 22 |

DN80(3 “) flange size specification sheet

| Flange standard | B | C | E | F | A | Number of bolts n | Bolt aperture |

| 150LB | 190 | 152 | 124 | 74 | 20 | 4 | 18 |

| 300LB | 210 | 168 | 124 | 74 | 25 | 8 | 22 |

| 600LB | 210 | 168 | 124 | 74 | 38 | 8 | 22 |

| 900LB | 240 | 191 | 124 | 74 | 54 | 8 | 26 |

| PN1.6/1.0 | 200 | 160 | 124 | 74 | 20 | 8 | 18 |

| PN2.5/4.0 | 200 | 160 | 124 | 74 | 24 | 8 | 18 |

| PN6.4 | 215 | 170 | 124 | 74 | 28 | 8 | 22 |

DN100(4 “) flange size specification sheet

| Flange standard | B | C | E | F | A | Number of bolts n | Bolt aperture |

| 150LB | 230 | 190 | 155 | 89 | 24 | 4 | 18 |

| 300LB | 255 | 200 | 155 | 89 | 32 | 8 | 22 |

| 600LB | 275 | 215 | 155 | 89 | 45 | 8 | 26 |

| 900LB | 290 | 235 | 155 | 89 | 50 | 8 | 33 |

| PN1.6/1.0 | 200 | 180 | 155 | 89 | 20 | 8 | 18 |

| PN2.5/4.0 | 200 | 190 | 155 | 89 | 24 | 8 | 22 |

| PN6.4 | 215 | 200 | 155 | 89 | 28 | 8 | 26 |

Order Guide

| Model | Transmitter type | |||

| SI-3151LT Pressure Level Transmitter | Flange liquid level transmitter | |||

| Code | Scale range | |||

| 4 | 0-4.0~40kPa(0-400~4000mmH2O) | |||

| 5 | 0-20~200kPa(0-2~20mH2O) | |||

| 6 | 0-70~700kPa(0-7~70mH2O) | |||

| 7 | 0-210~2100kPa(0-21~210mH2O) | |||

| 8 | customize | |||

| Code | Output form | |||

| E | Linear output 4-20mAdc | |||

| SF | Linear output 4-20mAdc +HART signal | |||

| F | MODBUS-485 signal | |||

| Code | Flange standard (high pressure side flange) | |||

| A | ANSI American Standard (HG20615) | |||

| D | DIN European Standard (HG20592) | |||

| Code | Process connection size | |||

| ANSI American Standard (HG20615) | DIN European Standard (HG20592) | |||

| 25 | 1” | DN25 | ||

| 40 | 1.5” | DN40 | ||

| 50 | 2” | DN50 | ||

| 80 | 3” | DN80 | ||

| 0 | 4” | DN100 | ||

| Code | Process connection pressure rating | |||

| ANSI American Standard (HG20615) | DIN European Standard (HG20592) | |||

| A | 150LB | PN16/25 | ||

| B | 300LB | PN40 | ||

| C | 600LB | PN64 | ||

| D | 900LB | PN100 | ||

| Code | High pressure side diaphragm | |||

| A | 316 stainless steel | |||

| B | Hastelloy C | |||

| C | Monel | |||

| D | Tantalum | |||

| E | Titanium | |||

| F | Special Requirements | |||

| Code | High pressure side insert tube length | High pressure side insert cylinder material | ||

| A | 0 mm | None | ||

| B | 50 mm | 316L Stainless steel | ||

| C | 150 mm | 316L Stainless steel | ||

| D | 200 mm | 316L Stainless steel | ||

| Code | High pressure side filling fluid | |||

| D | General silicone oil (-40~104℃) | |||

| F | High temperature silicone oil (-40~304℃) | |||

| S | Inert liquid (-40~204℃) | |||

| Low pressure side structural material | Flange (joint) | Exhaust/drain valve | Isolation diaphragm | Sensor filling fluid |

| 22 | 316 Stainless steel | 316 Stainless steel | 316 Stainless steel | Silicone oil |

| 23 | 316 Stainless steel | 316 Stainless steel | Hastelloy C | Silicone oil |

| 24 | 316 Stainless steel | 316 Stainless steel | Monel | Silicone oil |

| 25 | 316 Stainless steel | 316 Stainless steel | Tantalum | Silicone oil |

| 33 | Hastelloy C | Hastelloy C | Hastelloy C | Silicone oil |

| 35 | Hastelloy C | Hastelloy C | Tantalum | Silicone oil |

| 44 | Monel | Monel | Monel | Silicone oil |

| S2 | A remote transmission device (with a remote transmission device on the low-voltage side) | |||

| Code | Shell material | Conduit inlet dimensions | ||

| A | Low copper aluminum alloy polyurethane coating | M20×1.5 | ||

| B | Low copper aluminum alloy polyurethane coating | 1/2-14 NPT | ||

| C | Stainless steel | M20×1.5 | ||

| D | Stainless steel | 1/2-14 NPT | ||

| Code | Optional parts | |||

| M1 | 0~100% Linear indicator head | |||

| M4 | LCD multi – power digital display head | |||

| D1 | Side discharge valve at the top (only for the low pressure side of the low pressure side without remote transmission) | |||

| D2 | Side discharge valve at the top (only for the low pressure side of the low pressure side without remote transmission) | |||

| Da | Flameproof ExdIIBT5Gb;(explosion-proof certificate no. : CE16.1163) | |||

| Fa | Intrinsically safe ExiaIICT4 / T5 / T6Ga;(explosion-proof certificate no. : CE15.2354X) | |||

| CX | With corresponding 316 flushing ring |

Frequently

Asked

Questions

More Featured Industrial Pressure Transmitters

How to calibrate a pressure transmitter? How often?

10 Point Guide! Selection of Pressure Transmitters

In summary, Sino-Inst is a professional manufacturer of Pressure Level Transmitters, providing you with reliable and precise solutions for monitoring liquid levels in various tank and vessel applications. With years of experience and a commitment to quality, our products are designed to deliver accurate results and ensure smooth operations for your industry needs.

Contact us today to learn more about our Pressure Level Transmitters and experience the Sino-Inst difference. Our dedicated team is ready to assist you in selecting the best instrument for your application. Trust Sino-Inst for all your pressure level measurement needs and elevate your operations to new heights.

SI-3151LT Pressure Level Transmitter-Flange Mounting - Sino-Inst

Pressure level transmitters designed to ensure accurate measurement of liquid levels in a variety of tank environments. The Rosemount 3051L Level Transmitter manufactured by Emerson has become the ideal instrument for open or closed tank applications. Our SI-3151LT Pressure Level Transmitter was built using this as a prototype.

Product SKU: SI-3151LT Pressure Level Transmitter-Flange Mounting

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 400

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)