Hydrostatic liquid level measurement is based on the relationship between the static pressure of a liquid and the height of the liquid level.

Hydrostatic Level Measurement typically uses a pressure sensor to measure the hydrostatic pressure of a liquid. The pressure sensor converts the static pressure of the liquid into an electrical signal, which is then processed by a signal processor to finally obtain the height of the liquid level.

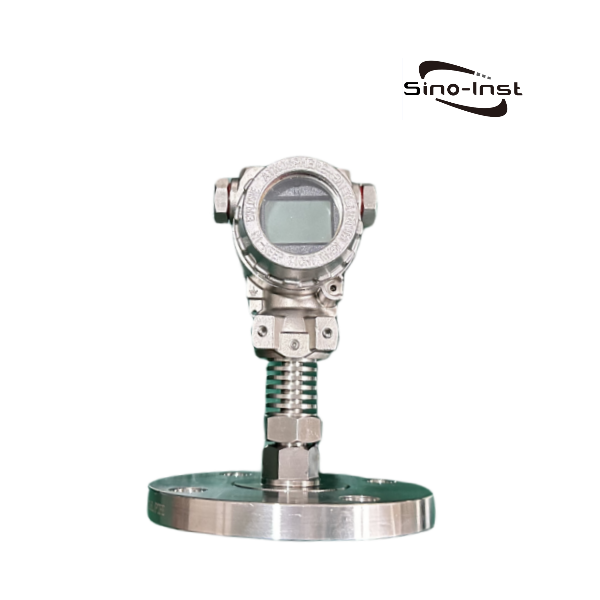

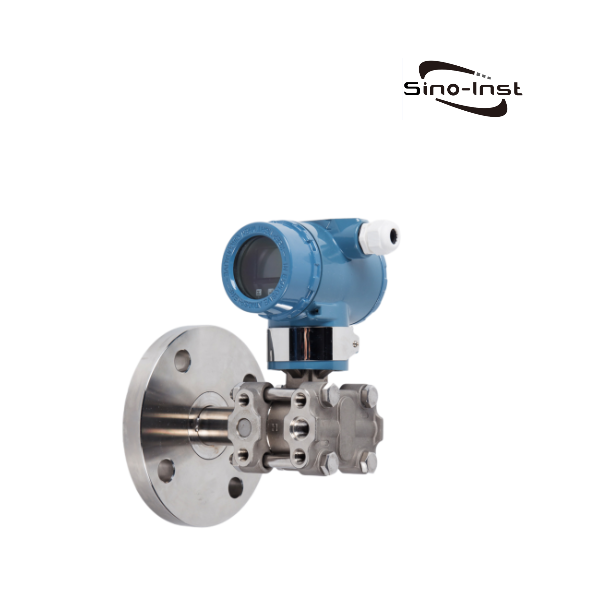

Featured hydrostatic level sensors

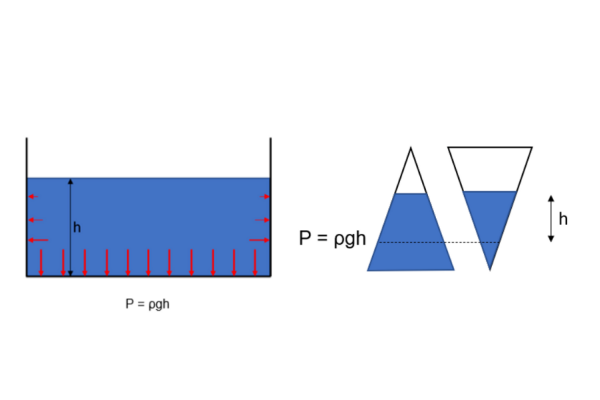

What is hydrostatic pressure?

According to Pascal’s law, the pressure of a liquid at rest is equal at all points in the liquid. When the height of the liquid increases, the pressure on the liquid also increases accordingly. This physical principle describes

Describes the gravitational effect of a stationary (not flowing) liquid at the measuring point. This kind of gravity is usually

Known as “hydrostatic pressure”. By measuring the static pressure exerted by a liquid, the height of the liquid level can be determined.

Hydrostatic pressure sensors can be used to measure the level or filling height of a liquid. Hydrostatic pressure measurement

The quantity is the liquid level measurement based on the static pressure effect of the stagnant liquid. This is the so-called “static pressure effect”. That is, regardless of the shape and volume of the container, the static pressure at the measuring point of the tank or container is always proportional to the height of the liquid.

hydrostatic level measurement working principle

Principle of hydrostatic level measurement:

After setting the measuring point, the pressure formula on the liquid surface of the sensor is:

Ρ = ρ .g.H + Po

In the formula:

P: Pressure on the liquid surface of the transmitter

ρ: Density of measured liquid

g: local gravity acceleration

Po: Atmospheric pressure on the liquid surface

H: Depth of the transmitter into the liquid

By introducing the pressure of the liquid into the positive pressure chamber of the sensor, and then connecting the atmospheric pressure Po on the liquid surface to the negative pressure chamber of the sensor to offset the Po on the back of the sensor, the pressure measured by the sensor is: ρ.g.H. Obviously, by By measuring the pressure P, the liquid level depth can be obtained.

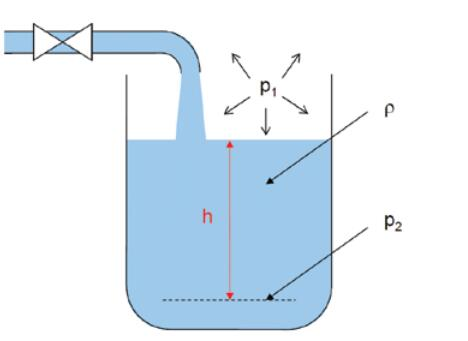

Liquid level measurement in open, non-airtight vessels

Hydrostatic level measurements in open or non-airtight tanks or vessels require continuous pressure compensation of the atmosphere above the liquid.

The atmospheric pressure acting on the media is an additional “pressure” just like the atmospheric pressure acting on the entire system (including the level sensor). If a pressure sensor with a relative pressure measuring cell is used, which is connected to the atmosphere (like a tank), then it can “automatically” compensate for the atmospheric pressure effect in the level measurement. This means that using a relative pressure sensor in an open container or tank can completely “eliminate” the influence of atmospheric pressure on the liquid during level measurement. Therefore, hydrostatic pressure is only related to the height of the liquid.

HydrostaticLevel Measurement Calculation Formula:

h=P2/(p*g)

h: Filling height / Filling level

P1: Ambient pressure

P2: Pressure at depth h

p: Density of the liquid

Rule of thumb (water): h [ m ] = p [ bar ] * 10

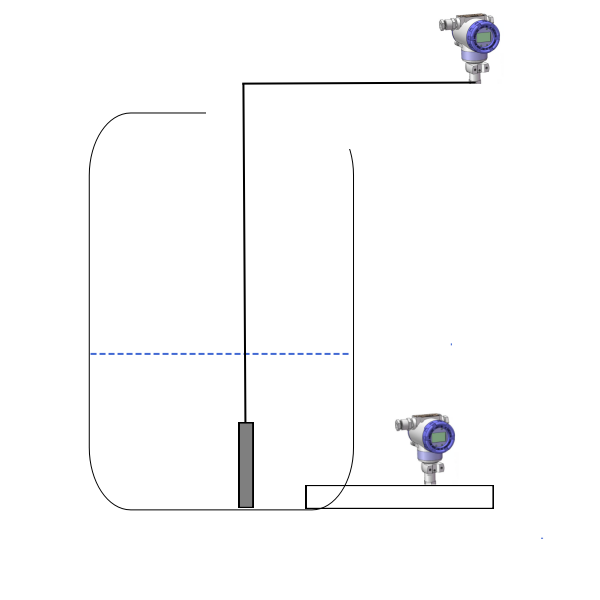

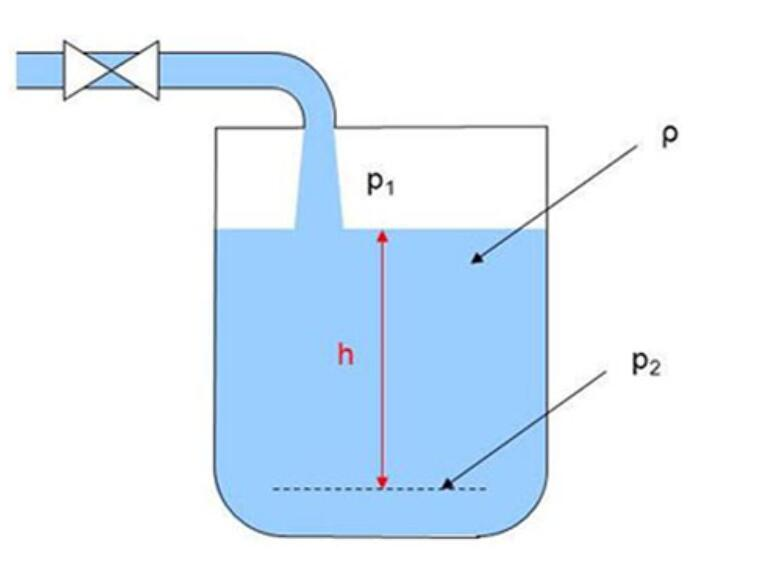

Liquid level measurement in sealed gas-tight vessels

In the production industry, liquid level measurements are often performed in sealed airtight containers. The measurement requires compensation for the gas phase enclosed above the liquid.

The confining gas phase pressure exerts an additional force on the liquid and distorts the static pressure measurement at the bottom of the vessel. Therefore, this distortion effect must be compensated for by additional gas phase pressure measurements.

A pressure sensor is usually used for gas pressure measurement. This application is often referred to as differential pressure measurement, where there is a certain deviation between the two separate pressure measurements.

This pressure deviation can be calculated using two separate sensors or an integrated differential pressure sensor. In this application, both relative pressure (sensor with atmospheric pressure compensation) and absolute pressure (sensor with sealed vacuum reference) sensors can be used.

HydrostaticLevel Measurement Calculation Formula:

h=(P2-p1)/(p*g)

h: Filling height / Filling level

P1 pressure on the surface

P2 pressure in depth h

density of the media

hydrostatic level measurement types

Through the above introduction, you should also understand that hydrostatic liquid level measurement applications can be divided into the following three categories:

- Pressure transmitter

- Submersible pressure transmitter

- Differential pressure level transmitter

For open tanks and independent containers, static pressure level measurement can be achieved by installing a pressure transmitter at the bottom of the tank. Generally, a flat membrane design is used, which can be a flat membrane flange or a flat membrane thread.

For liquid levels in open bodies of water, immersed pressure transmitters (‘level probes’ or ‘immersion probes’) are more commonly used. Widely used in well water, reservoir and sewage treatment industries. Immersion pressure transmitters are specially designed to operate normally under continuous immersion in liquid conditions. They differ from traditional pressure sensors mainly in media impedance, pressure tightness, cable quality and housing protection level.

For closed tanks and pressurized tanks, a differential pressure transmitter can be used to measure the pressure at the upper and lower points to calculate the liquid level. Read more about: Tank Level Measurement with Pressure Transmitters/DP Transmitters

Advantages and Disadvantages of Hydrostatic Level Measurement

Hydrostatic Level Measurement Applications

Hydrostatic level measurement has a wide range of applications in industrial processes. It is suitable for measurement of various liquids, including water, oil, chemicals, etc. Common applications include:

- Oil tank level measurement: used to measure the liquid level in oil, lubricating oil and other storage tanks in order to control the supply of oil and manage inventory.

- Pool level measurement: Used to measure the water level in wells, pools, and tanks to control water supply, prevent overflow, or maintain stable water levels.

- Chemical tank level measurement: used to measure the liquid level in chemical storage tanks, reactors and other containers to control the production process and ensure safe operations.

- Accumulation measurement: Determine the height of accumulation by measuring the static pressure of the accumulation, which is used to control the supply of materials and manage inventory.

More Pressure and Level Measurement Solutions

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

Compared with other liquid level measurement technologies, whether it is a submersible hydrostatic level transmitter or a pressure or differential pressure level transmitter, the cost of Hydrostatic Level Measurement is relatively low.

Hydrostatic level measurement technology is very simple and easy to use. Over the years, hydrostatic pressure measurement has become the most important measurement technology in continuous level measurement applications. The Hydrostatic Level Measurement technology is not only durable but also highly immune to a wide range of disturbances and unstable process conditions. Therefore, in the foreseeable future, it will still be the most important sensor technology in liquid level measurement applications.

We at Sino-Inst are professional manufacturers of hydrostatic level sensors. We also provide various customized pressure sensors, liquid level meters, etc. If you need to perform Hydrostatic Level Measurement or have related technical questions, please feel free to contact us.

-1.jpg)