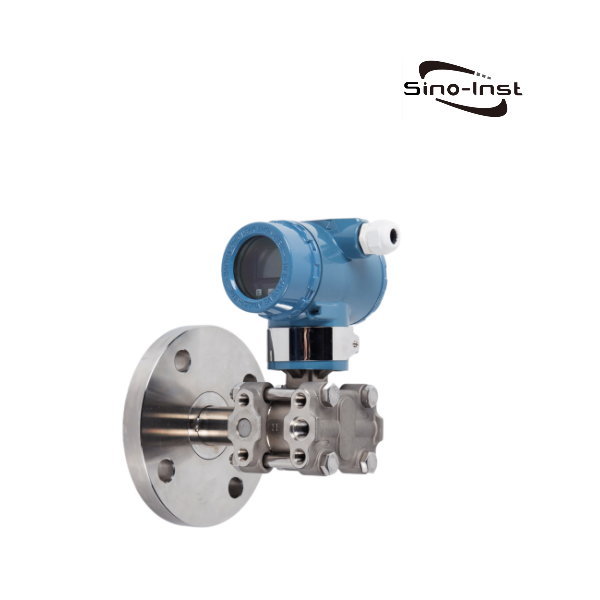

Small Differential Pressure Sensor SI-804DP is a low-cost diffused silicon differential pressure transmitter. It can measure the differential pressure of water, air and other media. And supports high and low temperature customization (-196℃~600℃). Optional LED, LCD and other local displays.

SI-804DP Small Differential Pressure Sensor has standard voltage, current, and RS485 signals to choose from. It is widely used in differential pressure, liquid level and flow measurement and control in process control, aviation, aerospace, automotive medical equipment, HVAC and other fields.

Features of Small Differential Pressure Sensor

- 316L stainless steel isolation diaphragm structure

- With current line control and reverse polarity protection

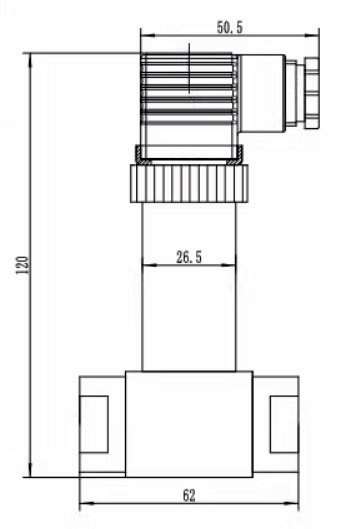

- Integrated and compact structure, easy to install

- Anti-shock, anti-vibration, anti-electromagnetic interference

- Convenient to measure differential pressure value

- Intelligent digital dedicated circuit

- LED digital tube on-site display, LCD intelligent display optional

- The appearance and structure are diversified and can be customized according to customer requirements, high and low temperature customization (-196℃~600℃).

Technical Parameters

| Performance parameters | Integrated differential pressure transmitter |

| Model | SI-804DP |

| Power supply | 12~36V power supply |

| Output signal | 4~20mA, 1~5V, 0-20mA, 0~5V, RS485, etc. |

| Measuring range | Any range within -0.1~10MPa |

| Compensation temperature | -10-70℃ |

| Storage temperature | -40~125°℃ |

| Medium temperature | -20~85℃(Customized-196℃~600℃). |

| Housing protection | IP65 |

| Pressure type | Differential pressure |

| Comprehensive accuracy | Level 0.2, 0.3, and 0.5 are optional |

| Zero temperature drift | ±0.03%F.S/C |

| Sensitivity temperature drift | ±0.03%F.S/C |

| Overload pressure | 200%F.S |

| Long term stability | ±0.2%F.S/y |

| Natural frequency | 5KHz~650KHz |

| Electrical connections | Direct Lead/Aero Plug/Hersman (or customized) |

| Measuring medium | Oil, water, gas and other media compatible with 316 stainless steel |

| Process connection | Threaded connection (size can be customized) |

Small Differential Pressure Sensor Working Principle

Before understanding how a differential pressure sensor works, let’s understand a few more basics.

how does a differential pressure sensor work

The core part of the diffused silicon differential pressure transmitter is a diffused silicon pressure sensor. This sensor is formed by diffusing doped materials on the silicon wafer to form a piezoresistive effect load measuring element. When pressure is applied to the silicon wafer, the resistance value of the silicon wafer changes.

In a differential pressure transmitter, two pressure ports are connected to the two pressure points to be measured. When the pressure between two points is different, the silicon wafer will undergo slight deformation, causing the resistance value on it to change.

Changes in resistance on the silicon chip are converted into electrical signals. Typically an analog voltage or current signal (e.g. 4-20mA) that is proportional to the pressure change. This signal can be further processed and analyzed.

At the same time, diffused silicon differential pressure transmitters usually include temperature compensation functions. Since temperature changes will affect the accuracy of the sensor, the built-in temperature sensor is used to detect changes in ambient temperature and automatically adjust the output signal to ensure measurement accuracy.

More Featured Differential Pressure Transmitters

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- Gauge Pressure vs Absolute Pressure | Differences and Relationships

- Industrial Water Pressure Sensors | Selection Guide

- How to calibrate a pressure transmitter? How often?

- 10 Point Guide! Selection of Pressure Transmitters

- Ultra Low-Micro Liquid Flow Measurement

- High-Pressure Flow Meters

- Industrial Liquid Nitrogen Flow Meters

- Flowmeters for Cryogenic Fluids Flow Measurement

Differential pressure sensors are widely used in various industries. Their main function is to measure the pressure difference between two points.

In addition to simple differential pressure measurement, it can also be widely used to measure the flow of fluids (such as water, gas, steam) in pipelines. Differential pressure sensors are used to measure the level of liquids in open or closed containers. In heating, ventilation and air conditioning (HVAC) systems, differential pressure sensors are used to monitor the condition of air filters, fan efficiency and air flow. and other applications.

We, Sino-Inst, are a professional manufacturer of differential pressure sensors. Our SI-804DP Small uses a diffused silicon differential pressure oil-filled core as the load measuring element. Supports various parameter customization, including high temperature, low temperature, signal output, etc.

If you need to purchase a differential pressure sensor or have related technical questions, please feel free to contact us!

Small Differential Pressure Sensor-Factory Customization | SI-804DP

Differential Pressure Sensor SI-804DP is a low-cost model, Can measure water, air and other media. Supports high and low temperature customization (-196℃~600℃).

Product SKU: SI-804DP Small Differential Pressure Sensor

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 150

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)