Reliable Flow Measurement Solution for water treatment.

Potable water flow meter also called Drinking water. Potable water flow meters are important for Domestic industries. Accurate flow measurement is essential to cost-conscious drinking water and potable water system. From water storage, transmission lines to raw water, water treatment and more. Reducing costs and improving flow control is on everyone’s mind. Depending on the requirements of your domestic water applicaiton, there are lots of options. Including: Insertion and inline electromagnetic flowmeters. Insertion Turbine meters with stainless steel wetted parts. Inline and clamp on type ultrasonic flow meters. Differential pressure flow meters offer unbeatable value in cost of installation and ownership. The extraction of drinking water usually starts from wells, reservoirs and large tanks. Large diameter pipes carry the extracted water and transfer them to the local distribution system. Therefore, Potable water flow meters usually need to be suitable for large diameter pipes, such as 6 inch, 4 inch, 3 inch. Of course, 2inch and 1inch pipe flowmeters are also very common. Sino-Inst’s potable water flow meters offer versatile, accurate flow measurement used in facilities across the globe.

Please feel free to contact Sino-Inst for further conversation.

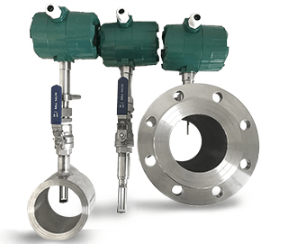

Featured Potable Water Flow Meters

Features of differential Potable Water Flow Meters

- Measurement not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

- No obstructing flow parts in the measuring tube. No pressure loss, and the requirements for straight pipe sections are low. Unique adaptability to slurry measurement;

- Reasonable selection of sensor lining and electrode material. So magmeter has good corrosion resistance and wear resistance;

- The converter uses a novel excitation method, low power consumption, stable zero point and high accuracy. Flow range can reach 150: 1;

- The converter can be integrated or separated with the sensor;

- The converter uses a 16-bit high-performance microprocessor. 2×16 LCD display, convenient parameter setting and reliable programming;

- The flow meter is a two-way measurement system. With three totalizers built in: forward total, reverse total, and difference total. It can display positive and reverse flow and has multiple outputs: current, pulse, digital communication , HART;

- The converter uses surface mount technology (SMT), with self-checking and self-diagnostic functions;

- Accuracy not affected by changes in fluid density, viscosity, temperature, pressure, and conductivity.

- No obstruction in the measuring pipe. No additional pressure loss. No moving parts in the measuring pipe. Life of the sensor is long.

- The induced voltage signal is formed in the entire magnetic field-filled space. And the voltage signal is the average value on the pipe loading surface. The straight pipe section required by the sensor is shorter and the pipe diameter is 5 times the length.

- Adopts the most advanced single-chip microcomputer (MCU) and surface mount technology (SMT). Reliable performance. High accuracy. Low power consumption, Stable zero point, and convenient parameter setting. Display the accumulated flow, instantaneous flow, flow rate, flow percentage, etc.

- Two-way measurement system can measure forward flow and reverse flow.

- Simple, durable design

- Easy installation and maintenance

- Reliable operation under a wide range of temperatures and pressures

- Turndown ratio is up to 35:1

- Good level of accuracy at an economic price

- Wide variety of process connections

- Low pressure drop

Advantages of throttling differential pressure flowmeter (orifice flowmeter)

- The standard orifice plate structure of the throttle piece is easy to copy. Simple, firm, stable and reliable in performance, long in service life and low in price;

- The throttling application range is extremely wide. All single-phase fluids, including liquid, gas, and steam, can be measured. Some mixed-phase flows, such as gas-solid, gas-liquid, liquid-solid, etc. can also be applied. General production processes and pipe diameters. The working condition (pressure, temperature) has products;

- All accessories can be used by all manufacturers if it is an international standard and can be used without calibration.

- Constant temperature heating design, direct mass flow measurement.

- No need for pressure/temperature transmitter (Calibration to compensate for pressure/warm).

- All products are designed with no moving parts. Wide range ratio:100:1 is sensitive to flow.

- Metal welded construction, plug-in ball valve. Low pressure loss.

- Performance intelligent microprocessor and moudulus; Digital to analog conversion chip;

- Low flow rate measurement is very sensitive;

- Suitable for all types of single or mixed gas flow measurement.

- Simple structure, easy to install and use.

- Energy saving. No additional resistance is generated and no pressure loss.

- Suitable for difficult to measure media and large pipelines.

- Simple structure, convenient installation, use and maintenance.

- Easy to maintain. The inspection parts are easy to repair and replace, and do not need to be cut off (except for the built-in type).

- The unique signal digital processing technology makes the instrument’s measurement signal more stable, strong anti-interference ability and more accurate measurement.

- Non-mechanical transmission parts are not easily damaged, maintenance-free, and long life.

- The circuit is more optimized and highly integrated; low power consumption and high reliability.

- Intelligent standard signal output. Friendly man-machine interface, multiple secondary signal outputs for your choice.

- Pipe section type small diameter measurement is economical and convenient. And the measurement accuracy is high.

- Universal flow meter for liquids, gases and steam measurement.

- Integrated pressure and temperature compensation, integrated energy calculator.

- Various designs: From version with reduced nominal diameter to dual device with two flow converters

- High long-term stability: no zero-point drift and lifetime K-factor

- Large turndown of typically 10:1 to 30:1 for gas/steam, or up to 40:1 for liquids

- Wide temperature range: –200 to +400 °C (+450 °C on demand)

How to Know Which Drinking Water or Wastewater Flow Meter is Right

Before choosing a drinking water flow meter, you need to consider some practical measurement factors as well as cost.

- Cost:

Typically when choosing a flow meter, the higher the accuracy the higher the cost. In addition to the cost of the meter, things to consider include what it costs to install, calibrate, replace your meter or shut down your line. As you compare different meters, be sure to amortize the total cost of the flow meter over its lifespan. - Application:

Whether the fluid media is drinking water or wastewater, knowing how conductive the media is in the pipe will be a big part of your decision. Some flow meters are affected by fluid temperature and operating pressure, so it’s critical that the meter you select has specifications that will meet your application needs. - Upstream and Downstream Piping:

When meters are placed too close to pumps, valves, elbows and other obstructions, unstable or irregular flow can impact performance. Before selecting a meter, check the specific pipe run requirements from the meter to a stable flow profile.

Domestic Water Flow Meter

Domestic water use includes indoor and outdoor uses at residences. And includes uses such as drinking, food preparation, bathing, washing clothes and dishes, flushing toilets, watering lawns and gardens, and maintaining pools. Domestic water use includes potable and non-potable water provided to households by a public water supplier (domestic deliveries) and self-supplied water use. Self-supplied domestic water use is typically withdrawn from a private source, such as a well, or captured as rainwater in a cistern.

Mechanical Water Flow Meter

There are various types of mechanical flow meters that measure flow using an arrangement of moving parts. Either by passing isolated, known volumes of a fluid through a series of gears or chambers (positive displacement, or PD) or by means of a spinning turbine or rotor.

All positive displacement flow meters operate by isolating and counting known volumes of a fluid (gas or liquid) while feeding it through the meter. By counting the number of passed isolated volumes, a flow measurement is obtained. Each PD design uses a different means of isolating and counting these volumes. The frequency of the resulting pulse train is a measure of flow rate, while the total number of pulses gives the size of the batch. While PD meters are operated by the kinetic energy of the flowing fluid, metering pumps determine the flow rate.

Water flow meter types

Water Flow Meters are flow meters measure and show the flow rate of water flow. Water flow measurement is important for inductrial applications, like the wastewater treatment. In principle, water flow meter types are: Electromagnetic (magnetic), Turbine, Ultrasonic, and DP. Coriolis and Oval Gear flow meters can also work for water flow measurement. These water flow meters, optional with digital display, battery, analog or pulse output. Material can be 316 stainless steel or special material.

Oil flow meter

Oil flow meter is also called a fuel oil flow meter. Reliable and Accurate oil flow measurement is important for industrial Oil and Gas system. Such as curde oil, natural gas, liquid natural gas, coal, diesel, and fuel. Sino-Inst offers digital and mechanical oil flow meters for inline oil flow measurement. Different flow sensors can meet the different measurement needs of customers. Positive displacement (Oval Gear) flow meters are the most wide used type. Magnetic, ultrasonic, turbine and mass flow meters also have their own characteristics. Like, Pressure and temperature range, output signal (pulse).

Differential pressure flow meters are also increasingly widely used oil flow meters. Because these advanced differential pressure flow meters have provided a level of performance once thought unachievable in real-world environments.

Flow Meters for Clean Water - a variety of technologies for monitoring the flow rate of clean water

Differential Pressure for Clean Water

Technical Support

The measurement of river and channel flow mainly uses the contact flow measurement technology. The most commonly used methods are the rotor flow meter method, the ultrasonic time difference method, and the Doppler ADCP method. The disadvantages of the rotameter are mainly manual operation and high labor intensity. However, the rotameter has the disadvantages of mechanical inertia and slow response speed. It cannot measure rapidly changing turbulence, and the rotameter needs regular verification and maintenance , When the flow is large, it cannot measure into the water. The disadvantage of the ultrasonic flowmeter used by the ultrasonic time difference method is that the instrument has higher requirements for water quality. The instrument must work in clean water, and there should be less floating objects in the water. Time accuracy is poor. The main disadvantage of the Doppler ADCP method is that it must carry out shipborne measurement, which requires manual operation. The accuracy is poor when measuring water quality with high sediment or impurity content. It cannot be measured for channels with smaller widths and when the flow is large The ship was also unable to work.

Of course, the canal / channel non-contact online flow measurement system adopts non-contact single or multiple fixed measurement point flow measurement technology. Which can realize continuous continuous flow measurement on the channel and the cross-section flow in the river, with high accuracy of flow measurement and water quality. Strong adaptability, no manual intervention required, maintenance-free and long service life.

The price of the flow meter is mainly determined by the following factors:

Flowmeter type

Pipeline diameter

Measuring medium

measure temperature;

Measure pressure

Pipe material

Output signal requirements:

Installation method

Of course, if you need to guide the cost of detailed flowmeters. Please contact our sales engineers.

Flow Metering Principals

- Differential Pressure Flowmeters

- Velocity Flowmeters

- Positive Displacement Flowmeters

- Mass Flowmeters

- For Open Channel Flowmeters – weirs, flumes, submerged orifices, current meters, acoustic flow meters and more

Flowmeters are devices that measure the rate of liquid, gas or vapor that passes through them.

Some flowmeters measure flow as the amount of fluid passing through the flowmeter during a time period (such as 100 liters per minute).

Other flowmeters measure the totalized amount of fluid that has passed through the flowmeter (such as 100 liters).

Flow measurement can be described by :

Q = A x v

Q is flow rate, A is the crosssectional area of the pipe, and v is the average fluid velocity in the pipe.

Putting this equation into action, the flow of a fluid traveling at an average velocity of a 1 meter per second,

through a pipe with a 1 square meter cross-sectional area is 1 cubic meter per second.

Note that Q is a volume per unit time, so Q is commonly denoted as the “volumetric” flow rate.

Now consider the following equation:

W = rho x Q

Where W is flow rate (again – read on), and rho is the fluid density.

Putting this equation into action, the flow rate will be 1 kilogram per second,

when 1 cubic meter per second of a fluid with a density of 1 kilogram per cubic meter is flowing.

(The same can be done for the commonly-used “pounds”. Without getting into details — a pound is assumed to be a mass unit.)

Note that W is a mass per unit time, so W is commonly denoted as the “mass” flow rate.

Now — which flow do you want to measure? Not sure? In some applications, measuring the volumetric flow is the thing to do.

Consider filling a tank.

Volumetric flow may be of interest to avoid overflowing a tank,

where liquids of differing densities can be added.

(Then again, a level transmitter and high level switch/shutoff may obviate the need for a flowmeter.)

Consider controlling fluid flow into a process that can only accept a limited volume per unit time.

Volumetric flow measurement would seem applicable. In other processes, mass flow is important.

Consider chemical reactions,where it is desirable to react substances A, B and C.

Of interest is the number of molecules present (its mass), not its volume.

Similarly, when buying and selling products (custody transfer) the mass is important, not its volume.

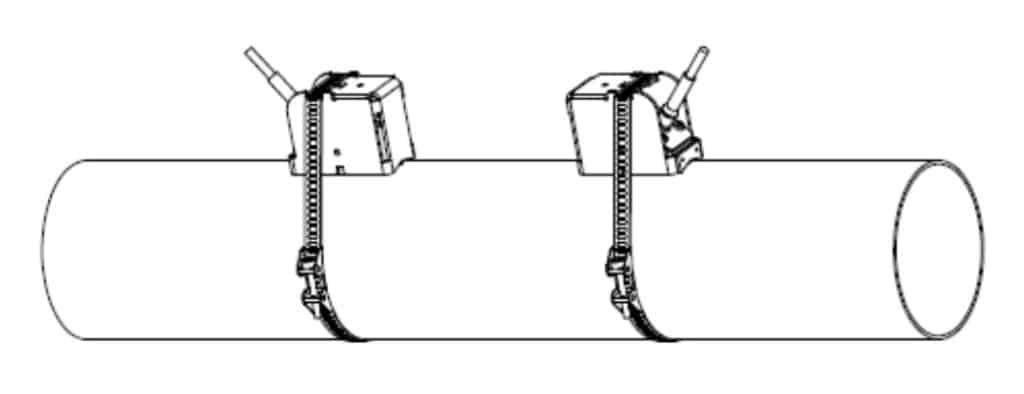

The non-intrusive detection method means that the detection medium will not cause wear to the detection instrument, so there will be no leakage.

In the flow detection of liquid media, the clamp-type ultrasonic flowmeter made by the ultrasonic detection method that has been used for a long time. And has become a standard flow detection product. In the field of chemical product production, especially in the measurement of corrosive media or media harmful to human health. People are most willing to use this non-immersive ultrasonic testing method. But these advantages are not limited to instruments for liquid detection.

In recent years, ultrasonic flow detection technology has been increasingly used for the detection of gaseous media. Especially in the process of natural gas transportation, transportation and storage, non-immersive detection methods have also been widely used. In the process gas detection, this non-immersive ultrasonic clamping detection technology is very beneficial.

We specialise in measuring the flow of a liquid in a pipe by using clamp on /strap on sensors. These are high frequency sensors that penetrate through the pipe wall and the liquid to determine the fluid velocity, flow rate and total. The most common types of clamp on technologies use a doppler or transit time propagation technique.

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes. Magnetic flow meters can be Remote type, compact type, insertion type. And ultrasonic flow meters are another choice, if you can not change your pipes. Both ultrasonic flow meters and magmeters are inline flow meters. Sino-Inst offers ultrasonic and magnetic flow meters, which offer the highest flow meter accuracy and reliability, as well as long-term stability and a low cost-of-ownership.

Digital Water Flow Meter

Digital water flow meter, is the electronic flow meter, which display the flow rate of water. Different Industrial liquid, different pipe for 1 inch, 2 inch, use different flow meters. The different sensors include turbine, ultrasonic, orifice plate, venturi, or with shut off switch. All these flow meters, with LCD display, 4-20mA output, or other outputs. The different designs of the flowmeters have a variety of applications.

Diesel Flow Meter

Diesel flow meter is the inline Turbine flow meter dedicated to measure diesel fuel flow. The diesel flowmeter uses a Turbine to measure. It first converts the flow rate to the speed of the turbine. And then converts the speed into an electrical signal that is proportional to the flow. This flow meter is used to detect the instantaneous flow and the total accumulated flow. Its output signal is frequency, which is easy to digitize.

High Viscosity Flow Meters

High viscosity flow meter is the flow meter measures the flow rate of viscous fluid flow. Common high viscosity liquids are: Crude oil, diesel, heavy oil. Asphalt, paraffin, honey, methanol, crude benzene, resin, and polyvinyl alcohol. Common high viscosity flow meters are: Oval Gear flow meters. Mass flow meter, Target flow meter, and Wedge flow meter also works for viscousity liquids.

Sino-Inst is a Professional potable water flowmeter manufacturer and supplier from China. Sino-Inst offers over 10 drinking water flow meter products.

A wide variety of water flow meter options are available to you, such as free samples, paid samples.

Sino-Inst’s flow meters service for industrial applications. Like: Cooling water, industrial gas, corrosives and brine, chemical processing, mining. Wastewater, energy, electronics, laboratories, medical, and many other industries.

-1.jpg)