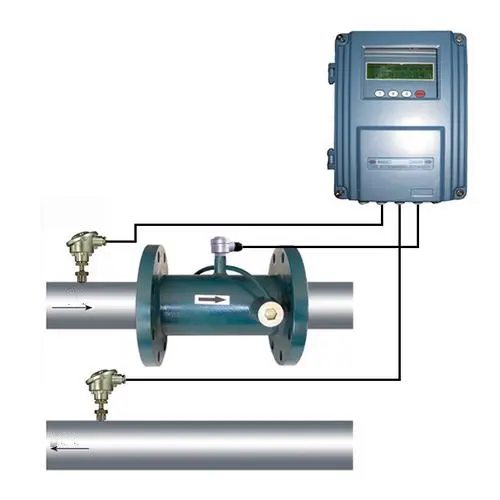

Ultrasonic Inline Flow Meter has both the host computer and the sensor installed on the measuring pipe. The protection level is high and can reach IP68. Paired with a temperature sensor, heat measurement can be achieved. It can be used for production monitoring, water balance debugging, heating network balance debugging, and energy saving monitoring. Ultrasonic Inline Flow Meter is an important flow measurement instrument in the production process.

Features of Ultrasonic Inline Flow Meter

- LCD display: Large-screen LCD display, instantaneous flow, cumulative flow, flow rate and other parameters.

- High-precision measurement: accuracy up to 1%, linearity 0.5%, repeatability accuracy 0.2%

- Large measuring range: Different types of sensors can realize pipe flow measurement of diameters DN15 ~ DN1200 (other customization).

- Powerful memory function: automatically memorizes the cumulative flow of the previous 512 days, the previous 128 months, and the previous 10 years, automatically memorizes the time and flow of the previous 64 power incoming and outage times, and automatically memorizes whether the working status of the flow meter is normal in the previous 32 days.

- Support heat measurement: equipped with a temperature sensor, temperature measurement can be achieved

- High-quality waterproof connector: aging-resistant, highly protective, protecting internal circuits. Can adapt to harsh working conditions on site.

- Intelligent output: 4-20mA current output, RS485/MODBUS data remote transmission. Relay output.

Ultrasonic Inline Flow Meter technical parameters

| Principle | Ultrasonic transit time measurement principle |

| Accuracy | Flow: ±1%; heat secondary meter (better than); repeatability: 0.2%; linearity 0.5% |

| Operate | Supports 4-key magnetic stick operation or 4-key touch keyboard and simulated keyboard software |

| Signal output | 4mA~20mADC |

| signal input | Can be connected to a three-wire temperature sensor to achieve heat measurement |

| Data interface | RS485 output, supports MODBUS and other protocols |

| Pipes | Steel, stainless steel, cast iron, cement pipes, copper, PVC, aluminum, fiberglass and other dense pipes are allowed to be lined |

| Tube inner diameter | DN15~DN1200 |

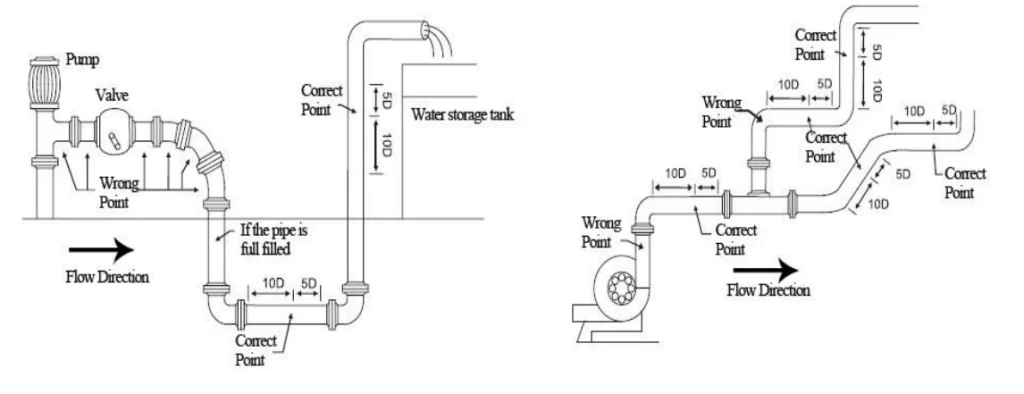

| Straight pipe section | The best installation point of the sensor is: 10D upstream, 5D downstream, and 30D away from the pump outlet (D is the inner diameter of the pipe) |

| Measuring medium type | Water, seawater, industrial sewage, acid and alkali liquids, alcohol, various oils and other single uniform liquids that can conduct ultrasonic waves |

| Temperature | -30℃~160℃ |

| Turbidity | 10000ppm and small bubble content |

| Flow rate | (0~±10)m/s |

| Temperature | Host: -20℃~60℃; Sensor: -30℃~160℃ |

| Humidity | Host: 85%RH; sensor: can be submerged in water, water depth <2m (note: the sensor needs to be filled with glue) |

| Power supply | 8V~36VDC (optional) or 85V~264VDC (optional) or 3.6V lithium battery power supply (optional) |

| Power consumption | 1.5W |

Optional Sensors

π type pipe segment sensor

Applicable to diameter DN15-DN32

Standard pipe sensor

Applicable to diameter DN40-DN1200

More Featured ultrasonic flow meters

What is the straight run requirement for ultrasonic flow meter?

In order to ensure the flow measurement accuracy of the ultrasonic flowmeter, when selecting the measurement point, it is necessary to select a location with a uniform fluid flow field. Generally, the following principles should be followed:

- The fluid in the pipeline under test must be full.

- The material of the pipe to be tested should be uniform and dense, and easy for ultrasonic waves to propagate. For example, vertical pipe sections (from bottom to top) or horizontal sections (preferably at the lowest point of the entire pipeline).

- The installation distance is more than 10 times the upstream diameter and more than 5 times the downstream diameter. (Note: Different instruments require different distances. The specific distance is subject to the instrument instructions). There are no valves, elbows, straight pipe sections with uniform diameters, etc. Measurement The point should be completely away from interference sources such as valves, pumps, high-voltage electricity, and frequency converters.

- 30D to pump outlet and half-open valve.

- Comprehensively consider the scaling situation of the pipeline, and it is best to choose a non-scaling pipeline section.

More Flow Measurement Solutions

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Electronic Flow Meters-Digital Display

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Fluid Flow Sensor | Types and Product List

- What Is Variable Area Flow Meter?

Ultrasonic Inline Flow Meter is a commonly used flow and heat measurement instrument. It is mainly used to measure fluid (liquid) flow and heat in closed pipe sections. It has many advantages such as high cost performance, wide application, good adaptability, relatively high precision, relatively economical and durable.

Sino-Inst’s Ultrasonic Inline Flow Meters precisely install ultrasonic sensors (commonly known as probes) on pipe sections of different specifications and standards. The pipe sections and probes are integrated into one, and form an ultrasonic flow meter and calorimeter with secondary instruments.

If you need to purchase Ultrasonic Inline Flow Meters, or have related technical questions, please contact our engineers.

Ultrasonic Inline Flow Meter-Pipe Segment Type - Sino-Inst

Ultrasonic Inline Flow Meter has both the host computer and the sensor installed on the measuring pipe. The protection level is high and can reach IP68. Paired with a temperature sensor, heat measurement can be achieved. It can be used for production monitoring, water balance debugging, heating network balance debugging, and energy saving monitoring. Ultrasonic Inline Flow Meter is an important flow measurement instrument in the production process.

Product SKU: Ultrasonic Inline Flow Meter-Pipe Segment Type

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 399

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)