There are more than a dozen categories and hundreds of models of flow meters on the market, all claiming to have unique measurement advantages. So how do you choose the flow meter that meets your needs?

Simply put, start with your actual measurement conditions. Select the most suitable flow meter based on your specific application parameters.

1. Define the Medium Being Measured

Current flow measurement technology is not universally applicable to flow meters for liquids, gases, steam, and solid powders.

If the measured medium is a liquid, you need to confirm the following:

- Name;

- Viscosity;

- Temperature;

- Pressure;

- Conductivity;

- Density;

- Flow range;

- Impurity content;

- Pipe diameter;

- Corrosiveness;

If the measured medium is a gas, you need to confirm the following:

- Name;

- Temperature;

- Pressure;

- Pipe diameter;

- Flow range;

- Humidity;

- Corrosiveness;

If the measured medium is steam, you need to confirm the following:

- Whether it is superheated steam or saturated steam;

- Pressure;

- Temperature;

- Pipe diameter;

- Flow range;

If the measured medium is a solid powder, you need to confirm:

- Name;

- Temperature;

- Pipe diameter;

- Particle size;

- Flow rate range;

- Abrasiveness;

2. Confirm the Measurement Purpose.

This means understanding why we need to measure and what we need to obtain from the measurement.

This means we need to understand why we need to measure and what we need to obtain through measurement. For example:

- Do we need to directly read the volumetric flow rate or the mass flow rate?

- What level of measurement accuracy is desired? For example, 0.5% or 0.1%?

- Does the flow meter need to be equipped with signal output for building a remote flow monitoring system?

3. Characteristics of Different flow meters

Different types of flow meters have different advantages, disadvantages and performance parameters. For details, please refer to: 11 Flow Meter Types and Their Advantages and Disadvantages. Before we choose a flow meter, it is best to understand the performance parameters of various flow meters. Mainly from the following aspects:

4. Flow Meter Installation Requirements.

Different flow meters have different requirements regarding pipe installation conditions, such as straight pipe sections and installation direction. The main considerations include: flow meter installation direction, fluid flow direction, upstream and downstream straight pipe section configuration, valve position, protective accessories, pulsating flow effects, vibration, electrical interference, and flow meter maintenance.

Among these, upstream and downstream straight pipe sections are important for most flow meters. Except for oval gear flow meters, GF gear flow meters, and Coriolis mass flow meters, which do not require upstream and downstream straight pipe sections, other types of flow meters require sufficient straight pipe sections upstream and downstream. Please refer to our detailed description for more information: Flowmeter Installation: Upstream and Downstream Straight Run Requirements

5. Flow meter cost

Based on our experience, we recommend that you choose a flow meter with a higher price within your budget. A higher price generally corresponds to better measurement performance, which is highly likely to reduce subsequent maintenance costs.

- Purchase cost of the flow meter.

When purchasing a flowmeter, the economic impact of different types of flowmeters on the entire measurement system should be compared. For example, measuring water pipe flow, DN300 large diameter. Then the external clamp ultrasonic flowmeter will cost less than other flowmeters. - Installation and maintenance costs

When purchasing a flow meter, you must consider not only the purchase cost of the flow meter, but also other costs, such as accessory purchase fees, installation and commissioning fees, maintenance and regular testing fees, operating fees and spare parts fees.

Flow Meter Comparison-Different Application Guidance

Below is a summary of flow meter options for some common application types. For your preliminary reference:

| Liquids | Clean Liquid | Dirty Liquid | Abrasive /Slurry | Corrosive | High Pressure | Cryogenic | High Temp | Mass Flow | Low Flow Rates <0.1m³/hr (0.44gpm) | Low Conductivity | |

| Coriolis Flow Meter | ■ | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Magnetic Flow Meter (4-wire) | ■ | ■ | ■ | ■ | O | O | o | O | |||

| Magnetic Flow Meter (2-wire) | ■ | O | ■ | O | O | O | O | ||||

| Capacitance Magnetic Flow Meter | ■ | ■ | ■ | ■ | O | O | O | ■ | |||

| Vortex Flow Meter | ■ | O | O | ■ | O | ■ | ■ | ■ | ■ | ||

| Variable Area Flow Meter | ■ | O | ■ | O | ■ | ■ | O | ■ | ■ | ||

| Differential Pressure (DP)Flow | ■ | O | O | O | ■ | O | O | ■ | ■ | ■ | |

| Gas and Steam | Clean Gas | Dirty Gas | Corrosive | Low Pressure | Saturated Steam | Superheated Steam | Cryogenic | High Temp | Mass Flow | Low Flow Rates | |

| Coriolis Flow Meter | ■ | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ||

| Vortex Flow Meter | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ||

| Variable Area Flow Meter | ■ | O | O | ■ | ■ | ■ | ■ | ■ | ■ | ||

| Differential Pressure (DP)Flow Meter | ■ | O | O | ■ | ■ | ■ | O | O | O | ■ | |

| ■ Designed for this service; O Applicable for this service under certain conditions -consult manufacturer | |||||||||||

Magnetic Flow Meters

Electromagnetic flow meters, also called mag meters or magnetic meters. Mag meter is ideal for wastewater applications, or any dirty liquid which is conductive or water based. Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better.

Turbine Flow Meters

Turbine flow meter is the most popular equipment to measure inline flow electronically. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, chemicals, water, cryogenic liquids, air, and industrial gases.

Vortex Flow Meters

Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. Pressure and Temperature compensation ensure measurement accuracy. When we use them to measure steam or gas.

Oval Gear Flow Meters

Industrial Oval Gear Flow Meters are positive displacement type volume meters. Sino-Inst offers High temperature and high pressure types oval gear flow meters for special use. Oval Gear Flow Meters are suitable for chemical fluids, like: fuel oil, water…

Mass Flow Meters

Mass Flow meters for all industrial flow measurement. Coriolis mass flow meters and Thermal mass flow meters. Coriolis Mass flowmeters are ideal for liquid flow measuring applications. And Thermal Mass flowmeters are for compressed gas applications.

Ultrasonic Flow Meters

Ultrasonic flowmeters measure the fluid flow rate in a pipe. With the sound waves transit time principle to determine the flow rate. Ultrasonic flow meters, with easy installation, could be clamp on, handheld, and portable.

Differential Pressure Flow Meters

Differential Pressure Flow Meters, also called DP flow meters. Differential pressure flow meters consist of flow sensors and pressure/differential transmitters. Flow sensors are the important part of differential pressure flow meters. Like: Orifice plate, Venturi tube, Wedge, V-cone and Averaging Pitot Tubes.

Selection examples

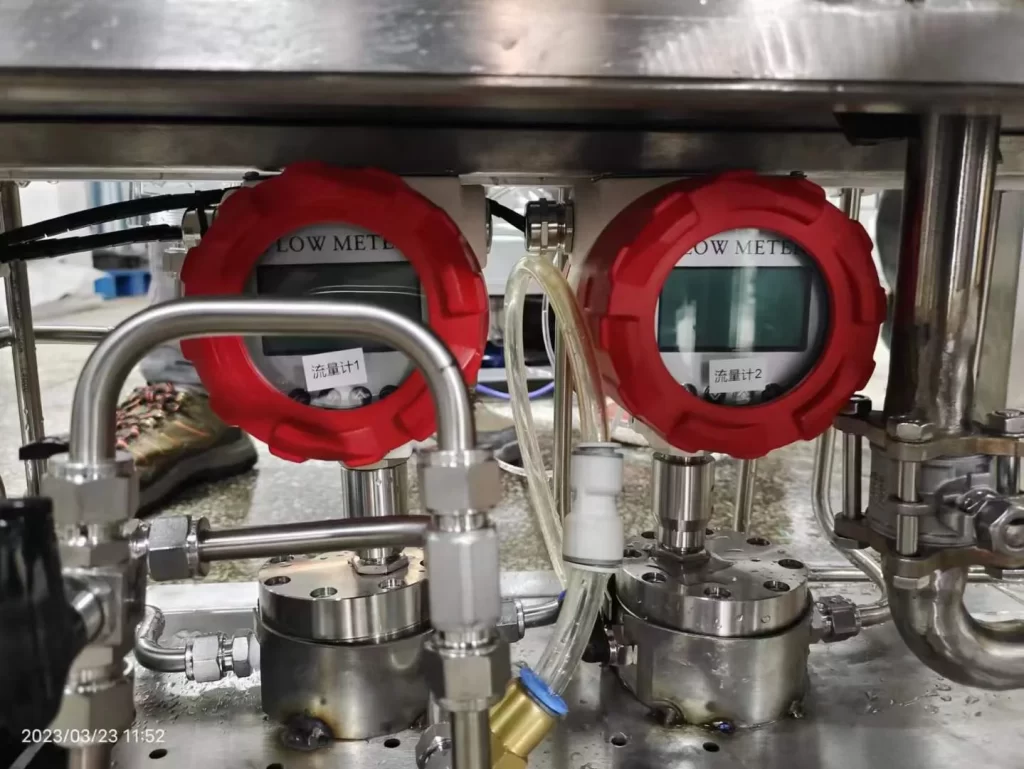

Refrigerant Flow Measurement for HVAC System

A customer from the United States was looking to purchase a flow meter to measure the flow rate of liquid R134A in their HVAC system. The system requirements and fluid properties were as follows:

- Fluid: Liquid R134A

- Connection tube size: 1/4″

- Flow rate: 5-250 L/h

- Operating temperature: -30°C to 150°C (-22°F to 302°F)

- Operating pressure: 0 to 600 psig

- Preferred output signal: 0-5V DC (alternative options: 0-10V DC, 4-20mA)

After evaluating various flow meter technologies, the customer selected our gear flow meter due to its suitability for their specific application. The gear flow meter provided accurate measurement for the refrigerant and met the temperature and pressure requirements. The selected gear flow meter had the following specifications:

- Model: GF-04

- Measuring range: 5-250 L/h

- Material: Stainless steel

- Connection: G3/8 thread

- Operating temperature and pressure: -30°C to 150°C (-22°F to 302°F), 0 to 600 psig

- Output signal: 0-5V DC

By choosing the gear flow meter, the customer was able to accurately measure and control the flow rate of liquid R134A in their HVAC system, ensuring optimal performance and energy efficiency.

More Flow Measurement Solutions

- Top 3 Flow Meters for PVC Pipes

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Top 4 Types of Pipeline Flow Meters-DN6~DN1000~DN6000

- Flow Measurement 101

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Volumetric Flow Meters: Comprehensive Guide and Product List

- Choosing the Right Inline Water Flow Meter

- Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

- Industrial Inline Flow Meters | Selection List

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- Top Guide to CO2 Flow Meters

- Ultrasonic Clamp on Flow Meter for Quick & Easy Measurements

Choosing the right flow meter for your application is critical to achieving accurate, efficient flow measurement. By considering the factors discussed in this Flowmeter Selection Guide and understanding the different flow meter technologies available, you can make an informed decision and find the product that best suits your specific needs.

As an experienced manufacturer and supplier, Sino-Inst offers a variety of flow meters and supports customization to meet your unique requirements.

Contact us today to discuss your flow meter needs and learn how our expertise can help you improve process control and efficiency.

-1.jpg)