Industrial Nitrogen Gas Flow Measure Solutions

Industrial Nitrogen Gas Flow Meters are digital flow meters for N2 gas measurement. Nitrogen gas is a widely used material involved in operations across an array of industries. Nitrogen is an inert gas. Nitrogen is required in many processes in the chemical and pharmaceutical industries. It is mainly used as a protective gas to prevent explosive atmospheres. For example, when handling dusty products or solvents. In many places, nitrogen is supplied centrally, as is compressed air. A tank filled with liquid nitrogen ensures continuous supply and supplies the expanded gas to the piping system. Consumers extract the required amount of nitrogen from the piping system. We designed our nitrogen flow meters to be easy to use, affordable and complete.

Sino-Inst supplies a wide range of Flow meters for use with nitrogen, if you require any further help or information, please contact us.

Featured Industrial Nitrogen Gas Flow Meters

Technologies for Industrial Nitrogen Gas Flow Measurement

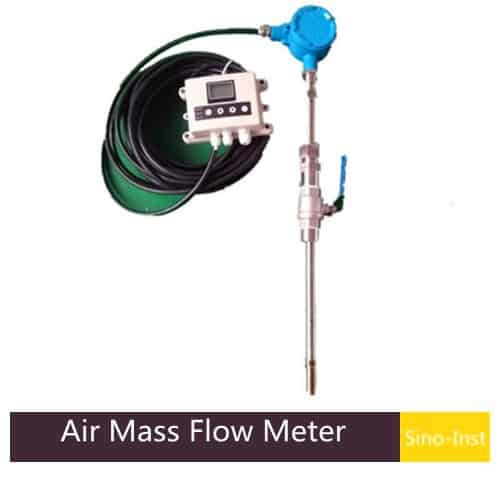

Thermal Mass Flow Meter (TMF) also called Thermal Flow Meter.Thermal Mass Flow Meters measure the mass flow of a fluid. An external heat source will heat the pipe or the fluid. Temperature field changes when the fluid flows through the pipe. Thermal mass flow meter measures the relationship between the energy required to increase the temperature of a fluid and the mass of the fluid to measure the mass flow of the fluid. The flowmeters directly measure the mass flow or normalized volume flow of gases. Without any additional pressure and temperature compensation. Generally, thermal mass flow meter used to measure the mass flow of a gas (like natural gas).

Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity.

Even for the steam flow rate, Vortex flow meters are the perfect choice. Pressure and Temperature compensation ensure measurement accuracy. When measure steam or gas flow in pipes with variable operating pressure and temperature.

Applications in the chemicals and petrochemicals industries. For example, in power generation and heat-supply systems. Involve widely differing fluids: saturated steam, superheated steam, compressed air. Nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water. Solvents, heat-transfer oils, boiler feedwater, condensate, etc.

A turbine flow meter is constructed with rotor and blades. Turbine flow meters use the mechanical energy of the fluid to rotate the rotor in the flow stream. Turbine flow meter is the most popular equipment to measure inline flow electronically. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, chemicals, water, cryogenic liquids, air, and industrial gases. Turbine Flow Meters are easy to maintain, durable and versatile.

Differential Pressure Flow Meters also called DP flow meters. Differential pressure flow meters consist of flow sensors and pressure/differential transmitters. DP Flow Meters measure the flow rate based on the differential pressure measured by the flow sensor parts. Flow sensors are the important part of differential pressure flow meters. Like: Orifice plate, Venturi tube, Wedge, V-cone and Averaging Pitot Tubes.

Differential pressure (DP) flow meters are suitable for applicaitons, like: water, gas, steam, oil….

Features of Nitrogen Gas

Nitrogen, N2, is usually a colorless and odorless gas. In general, nitrogen is less dense than air. Nitrogen accounts for 78.08% (volume fraction) of the total atmosphere and is one of the main components of air. Under standard atmospheric pressure, when nitrogen is cooled to -195.8 ° C, it becomes a colorless liquid. And when cooled to -209.8 ° C, liquid nitrogen becomes a snow-like solid. The chemical nature of nitrogen is inert and it is difficult to react with other substances at room temperature. So it is often used to make preservatives. Yet, under high temperature and high energy conditions, chemical changes can occur with certain substances to make new substances useful to humans.

Common Industrial Uses for Nitrogen Gas

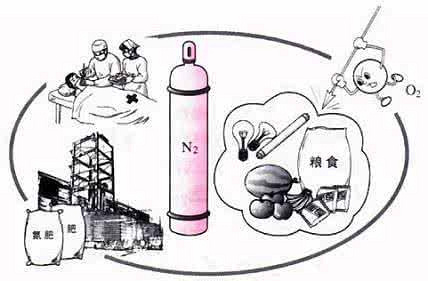

Nitrogen gas has a wide range of uses in the chemical, petroleum, electronics, food, metal smelting and processing industries.

Filling the oil well with nitrogen can not only increase the pressure in the well, but also increase the oil production. The filled nitrogen can also be used as a cushion in the measurement of the drill pipe. The possibility of squeezing the lower test tube string by the mud pressure in the well is completely avoided. Besides, nitrogen is also used in downhole operations such as acidification, fracturing, hydraulic perforation, and hydraulic packer setting. Filling natural gas with nitrogen can reduce the calorific value. When replacing the pipeline with crude oil, liquid nitrogen can be used to inject the materials at both ends to solidify and block. Using nitrogen for pressure transportation of pulverized coal is safe, convenient and economical.

Nitrogen is the main raw material for the synthesis of ammonia. The nitrogen required for ammonia synthesis does not need to be separated and purified, and is directly derived from air. During the production of ammonia synthesis gas, the oxygen in the air and the hydrocarbon raw materials undergo a high-temperature catalytic reaction. After conversion, decarbonization, and methanation, a hydrogen-based mixture containing a small amount of methane, trace amounts of carbon monoxide and carbon dioxide is generated. Nitrogen and argon in the air do not participate in the reaction, and directly enter the synthesis gas, thereby obtaining ammonia synthesis gas mainly composed of hydrogen and nitrogen. As ammonia, carbon monoxide, and carbon dioxide easily poison the synthesis catalyst, methane and argon-based synthetic inert substances, and a large accumulation will reduce the synthesis efficiency. Purification of synthesis gas using the liquid nitrogen washing process can prolong the catalyst lifetime and improve Ammonia synthesis efficiency.

Nitrogen is also the main raw material for the synthesis of calcium cyanamide, sodium cyanide and silicon nitride.

High-purity nitrogen can be used as auxiliary gas for the production of polyethylene. For example, a polyethylene production line with an annual output of 10 million tons needs to provide 4,400 standard cubic meters of pure nitrogen per hour.

Utilizing the chemical inactivity of nitrogen, nitrogen is filled in the reactors and storage tanks of many flammable liquid substances. Not only does it protect materials from oxidation and maintain product quality. It also ensures safety and prevents combustion and explosion accidents.

Nitrogen is mainly used as protective gas and purge gas in the metallurgical industry. In the process of rolling steel and metal heat treatment, due to the expansion of nitrogen, the high temperature oxidation of the metal is reduced, and the surface is smooth. Filling non-ferrous metal smelting furnace with nitrogen can reduce the amount of oxygen and temperature, reduce oxidation, and improve product purity. Purge the molten steel with nitrogen to reduce the hydrogen content in the steel and increase the strength of the product. Blowing in 86% nitrogen during blast furnace operation can reduce coke consumption and extend service life. Arc plasma

The furnace is filled with nitrogen to produce nitrided high-speed tool steel.

Purge silicon wafers with dry nitrogen in the electronics industry to keep them dry and clean. In the large-scale integrated circuit production process, high-purity nitrogen can be used as a carrier gas, an inert protective gas, and a packaging gas for a chemical reaction gas.

High-purity nitrogen is a commonly used carrier gas in gas chromatography analysis. Liquid nitrogen is an important source of cold in scientific instruments or scientific experiments. For example, the single crystal lithium detector of the EDAX spectrometer needs to be stored and used at the temperature of liquid nitrogen. Many tests are performed at low temperatures, and the cooling capacity is provided by liquid nitrogen in most cases. Liquid nitrogen can be used as a cold source for various cold traps, cold pumps and cryogenic superconductors.

Nitrogen is mainly used as a protective gas in the food industry. For example, in the fruit and vegetable warehouse, nitrogen is filled to expel oxygen, which inhibits the growth of mold and the production and release of ethylene. It delays the metabolism of fruits and vegetables and lengthens the preservation period. In the storage of grain, filling nitrogen can delay aging. For a long time, maintain the aroma of new rice. With the acceleration of the pace of life, fast food is receiving more and more attention. Filling nitrogen in packaging containers can extend the shelf life of these foods. Foods such as fish and meat can be frozen with liquid nitrogen to achieve the effect of rapid freezing, prevent the moisture in the tissue from forming a vitreous body, so that the tissue is not damaged, and the original taste can be maintained after reheating.

In the biological and medical fields, nitrogen mainly uses the low-temperature properties of liquid nitrogen and is inactive and non-toxic. It is an ideal cold source. Liquid nitrogen has been widely used in the preservation of animal semen, human tissue, and surgery.

Liquid nitrogen also has certain applications in the construction field. For example, large-volume concrete exotherms when solidified, and cracks often occur inside to reduce strength. Using liquid nitrogen as a coolant can greatly increase the strength of concrete. Liquid nitrogen has a unique role in salvaging the sunken ship. Liquid nitrogen can generate pressure after gasification and can be used as a power source. Liquid nitrogen is also used in condensing the atmosphere into clouds, simulating the space environment, forming low-temperature wind-driven channels, recovering radioactive waste, removing scale layers on metal surfaces, making ceramic superconducting cables, crushing and recycling waste rubber, and plastic products.

Nitrogen can also be used as a fire extinguishing gas. Filling the bulb with nitrogen or argon alone can extend the life of the bulb.

In short, nitrogen is widely used in the national economy and people’s livelihood. And it is closely related to human life, production activities and scientific experiments.

Flow Measurement of Nitrogen

Even though nitrogen gas is usually considered inert, that doesn’t mean its use doesn’t need to be controlled precisely counting on its use. within the aforementioned example involving nitrogen flushing and food preservation, using an appropriate flowmeter to watch the speed of flow can make sure that a correct amount of gas is dispensed for the precise need. That way packages aren’t overinflated, which may end in wasted gas also as packaging or product damage, while also ensuring enough is added to preserve and protect the food products.

A similar need for precise use is involved when nitrogen is employed to make electrical components, especially when spaces must be filled and therefore the walls are otherwise delicate or sensitive to excess pressure. for instance , an excessive amount of gas forced into a diode could lead on to wreck , rendering the part useless.

Since adding gas to a sealed container increases the pressure, it’s important to watch the speed of flow to stay the associated pressure at the proper level of the aim . At times, an RF pickup is a perfect method for monitoring flow as they’re ready to monitor the speed even at near zero speeds. this will be critical in delicate situations or where the quantity being dispensed in especially small, requiring a coffee speed to avoid overfilling.

Industrial Liquid Nitrogen Flow Meters

Liquid Nitrogen Flow Meter is a Cryogenic Flow Meter. Nitrogen (N2), which is usually a colorless and odorless gas, and generally nitrogen gas has smaller density than air. Nitrogen accounts for 78.08% (volume fraction) of the total amount of the atmosphere and is one of the main components of air. At a standard atmospheric pressure, nitrogen gas was cooled to -195.8 ° C to become a colorless liquid. When cooled to -209.8 ° C, the liquid nitrogen became a snowy solid. For liquid nitrogen flow rate, Sino-Inst offers turbineflow meters, mass flow meters, and target flow meters. While measuring liquid nitrogen flow, pay attention to nitrogen blanketing for liquid nitrogen storage tanks and pipes.

Technical Support

Inline Compressed Air Flow MetersWater Flow Meter Types

Water Flow Meters are flow meters measure and show the flow rate of water flow. Water flow measurement is important for inductrial applications, like the wastewater treatment. In principle, water flow meter types are: Electromagnetic (magnetic), Turbine, Ultrasonic, and DP. Coriolis and Oval Gear flow meters can also work for water flow measurement.

Coriolis Mass Flow Meter Technology

Coriolis mass flow meter also called micro motion flow meter. Coriolis mass flow meter is the mass flow meter beasd on the coriolis force. Coriolis mass flow meter and thermal mass flow meter are the most common mass flow meters. Corolis mass flow meters are best choice for all process and custody transfer (CT) applications. Coriolis mass flow meter can measure different values at the same time. Mass, volume flow, density and concentration measurement of liquids and gases.

Natural Gas Flow Meter

Natural Gas Flow Meter, is the inline flow meter for natural gas pipeline. Like: thermal mass flow meter, ultrasonic natural gas flow meter, natural gas turbine flow meter. Intelligent Gas Precession Vortex Flowmeter, and differential pressure flow meter. These are the most common inline natual gas flow meters with digital display. According the natural gas pipeline measurement conditions, select suitable natural gas flow meter. Such as: pressure, temperature, length of straight pipe, diameter of pipe, insertion or remote installation, etc,.

Inline Compressed Air Flow Meters

Compressed Air Flow Meter is the digital flow meter work for the air compressor. Thermal mass, vortex, portable ultrasonic, and DP flowmeters are commom gas flow sensors. Air consumption is an important info for industrial inline gas flow pipe. Compressed air is the most expensive form of energy in manufacturing plants. And compressure air accounts for up to 20% of the overall energy costs.

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes. Magnetic flow meters can be Remote type, compact type, insertion type. And ultrasonic flow meters are another choice, if you can not change your pipes. Both ultrasonic flow meters and magmeters are inline flow meters.

Digital Water Flow Meter

Digital water flow meter, is the electronic flow meter, which display the flow rate of water. Different Industrial liquid, different pipe for 1 inch, 2 inch, use different flow meters. The different sensors include turbine, ultrasonic, orifice plate, venturi, or with shut off switch. All these flow meters, with LCD display, 4-20mA output, or other outputs.

Nitrogen flow meter supplier

Over 10 nitrogen gas flow meter products are offered for sale by Sino-Inst on sino-inst.com, of which flow meters accounts for 99%, gas meters accounts for 50%, and gas analyzers accounts for 1%. A wide variety of nitrogen gas flow meter options are available to you. Sino-Inst sells nitrogen gas flow meter on sino-inst.com, mainly located in China. The top countries of sales are China, Europe, and South Korea, from which the percentage of nitrogen gas flow meter supply is 99%, 1%, and 1% respectively.

-1.jpg)