| Measurable Medium | Gases, Liquids, Steam |

| Diameter | DN15~DN2000 |

| Temperature | -200℃~500℃ |

| Pressure | 0~42MPa |

| Accuracy | 0.5%~1.5% |

| Compensation Method | Temperature compensation, Pressure compensation |

| Output Signal | Two-wire/Four-wire 4-20mA, Pulse, 0-5V, RS485, HART |

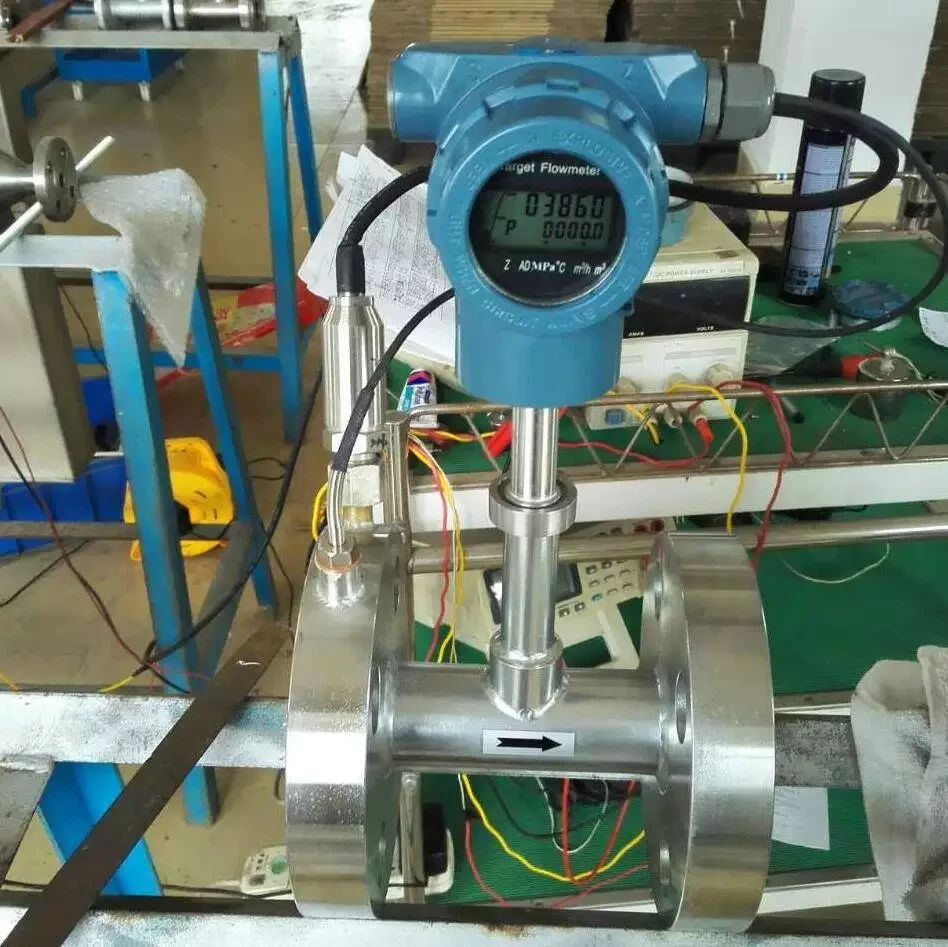

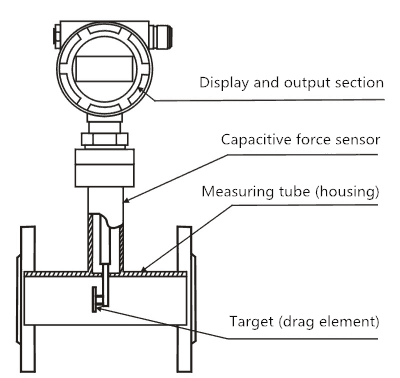

What is a Target Flow Meter?

A target flow meter is an instrument that measures flow rate by utilizing the pressure difference caused by the fluid passing through a target. Target flow meters are also known as drag force flow meters.

When the medium flows through the measuring pipe, a pressure difference is generated due to its kinetic energy acting on the flow obstruction (target plate), resulting in a force on the obstruction. The magnitude of this force is directly proportional to the square of the fluid velocity. This is somewhat similar to differential pressure flow measurement.

Features

Technical Specifications

| Medium | Liquid, Gas, and Steam | ||||||

| Caliber | Pipe type | Clamp type | Insertion type | ||||

| 15~300mm | 15~600mm | 100~2000mm | |||||

| Pressure | 0.6~10MPa | 0.6~42MPa | 0.6~42MPa | ||||

| Medium Temperature | -196°C~+450°C ( Confirming the temperature range before purchase) | ||||||

| Precision | ±0.2% | ±0.5% | ±1.0% | ±1.5% | ±2.5% | ||

| Range | 1:03 | 1:05 | 1:10 | 1:10 | 1:10(Steam) | ||

| Compensation | Temperature compensation; Pressure compensation | ||||||

| Repeatability | 0.1%~0.08% | ||||||

| Power Supply | 3.6V lithium battery, 24V DC | ||||||

| Output | LCD display, and 4~20mA, 0~10V, impulse or RS485 (Optional), HART | ||||||

| Material of measure tube | Carbon Steel;304;316L; Being able to provide other according to user requests | ||||||

| Explosion- Prevent Symbol | ExiallCT4, ExiallBT4 | ||||||

| Flange specifications | The flange specifications of the flow meter are in accordance with GB / T series standards, and can also be specially processed according to user requirements. | ||||||

| Protection class | Liquid, Gas and Steam | ||||||

Order Guide

| SI-3706 Target Flow Meter | ||||||||||||||||||||||||||||||

| Code | Diameter | |||||||||||||||||||||||||||||

| 0010 | DN10 | |||||||||||||||||||||||||||||

| 0100 | DN100 | |||||||||||||||||||||||||||||

| …… | ||||||||||||||||||||||||||||||

| 5000 | DN5000 | |||||||||||||||||||||||||||||

| Code | Connection | |||||||||||||||||||||||||||||

| F | Pipe flange type | C | Plug-in type | D | Clamp type | U | Continuous flow disassembly | L | Threaded type | E | Others | |||||||||||||||||||

| Code | Medium | |||||||||||||||||||||||||||||

| L | Liquid | G | Gas | S | Steam | |||||||||||||||||||||||||

| Code | Pressure | |||||||||||||||||||||||||||||

| A | 0.6 Mpa | E | 2.5 Mpa | I | 10 Mpa | M | 20Mpa | |||||||||||||||||||||||

| B | 1.0 Mpa | F | 4.0 Mpa | J | 11 Mpa | N | 25 Mpa | |||||||||||||||||||||||

| C | 1.6 Mpa | G | 5.0 Mpa | K | 15 Mpa | O | 26 Mpa | |||||||||||||||||||||||

| D | 2.0 Mpa | H | 6.3 Mpa | L | 16 Mpa | P | 42 Mpa | |||||||||||||||||||||||

| Code | Temperature | |||||||||||||||||||||||||||||

| C | -20 ~ 80°C | |||||||||||||||||||||||||||||

| Z | 80~ 200°C | |||||||||||||||||||||||||||||

| G | 200~500°C | |||||||||||||||||||||||||||||

| D | -200~-20°C | |||||||||||||||||||||||||||||

| Code | Output | |||||||||||||||||||||||||||||

| P | Pulse output | H | HART | |||||||||||||||||||||||||||

| I | 4~20mA | K | Switch output | |||||||||||||||||||||||||||

| R | Communication output | |||||||||||||||||||||||||||||

| Code | Explosion-proof mark | |||||||||||||||||||||||||||||

| A | Intrinsic safety | D | Flameproof | |||||||||||||||||||||||||||

| Code | Shell material | |||||||||||||||||||||||||||||

| C | Carbon steel | |||||||||||||||||||||||||||||

| S | 304 stainless steel | |||||||||||||||||||||||||||||

| T | 316L | |||||||||||||||||||||||||||||

| Code | Sensor material | |||||||||||||||||||||||||||||

| H | Hastelloy | |||||||||||||||||||||||||||||

| T | titanium | |||||||||||||||||||||||||||||

| S | 304stainless steel | |||||||||||||||||||||||||||||

| E | Specific material | |||||||||||||||||||||||||||||

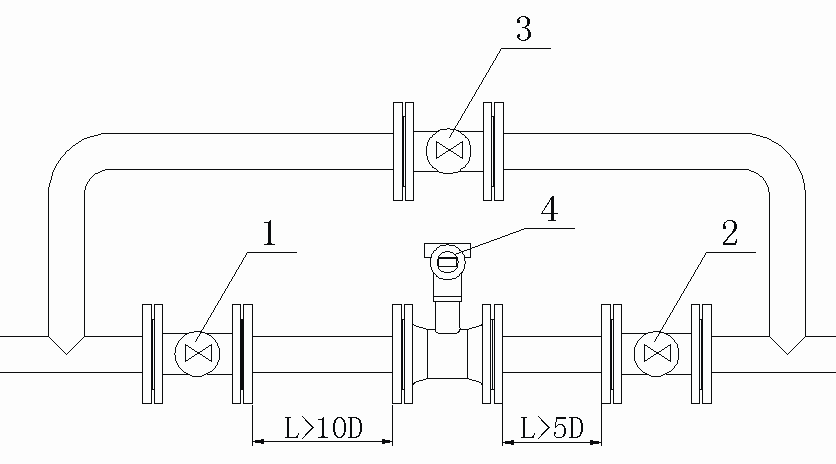

The target type flowmeter is suitable for a variety of occasions and measurements of various media. In order to ensure satisfactory results, it is recommended to pay attention to the following when selecting a model:

1) Determine the required common flow, and determine the maximum flow by 1.5 to 2.5 times the common flow.

2) Specify the standard of the mounting flange and the form of seal, especially for special installation requirements.

3) When ordering, the user should indicate the medium of the fluid to be tested and give the density of the medium.

4) If you need to measure special media, you can directly recommend the required measuring tube materials in addition to the measuring tube materials provided by the company.

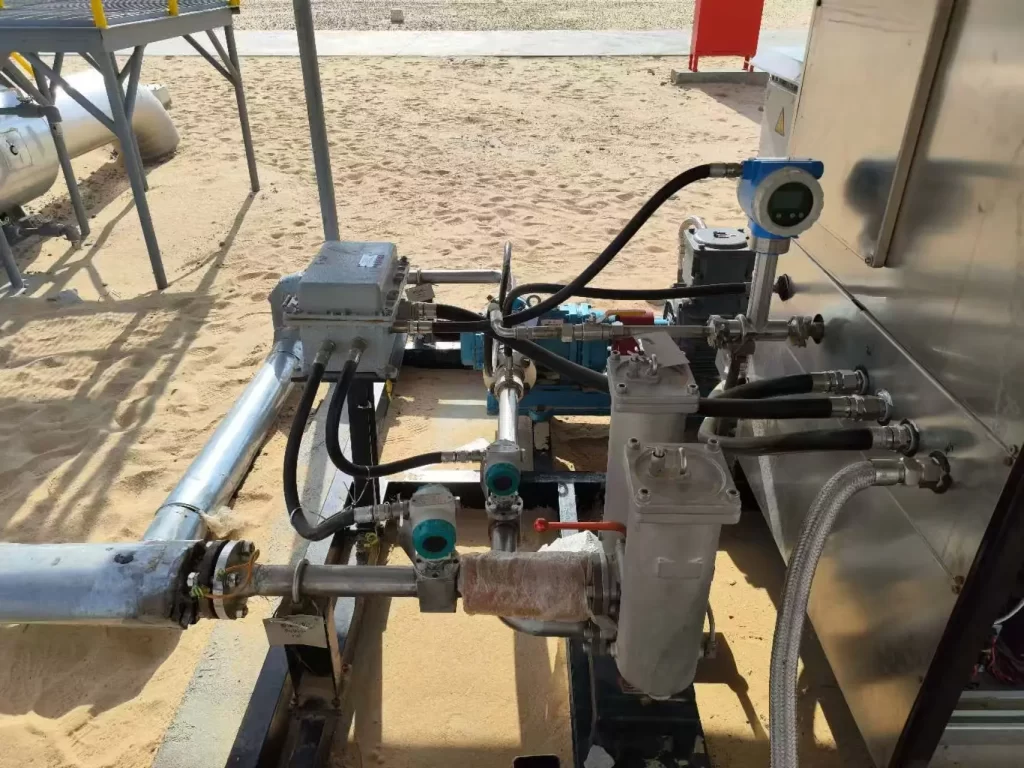

Application Case 1:

Coke Oven Gas Measurement in a Coking Plant (containing oil mist + dust)

Application: The force generated by the coke oven gas impacting a ceramic target plate is converted into a signal by a sensor, which is then converted into a gas flow rate.

We configured a wide flow channel and back-purging interface for the user to prevent oil and dust accumulation from affecting the force on the target plate.

Results: Data error ±0.4%, no blockage for 6 months, recovering 5000 m³/month more coke oven gas than ordinary flow meters.

Application Case 2:

PAC Dosing Measurement in a Wastewater Treatment Plant (containing particles + viscous substances)

Application: The PAC solution impacts an anti-stick target plate, and the force signal is converted into flow rate data.

We customized a Teflon anti-stick coating and a removable target plate for the user, ensuring the medium does not stick to the wall and is easy to clean.

Results: Accurate flow measurement, saving 15% on PAC dosage, resulting in a monthly saving of USD200 in chemical costs.

Technical Support

LNG and CNG Flow Measurement

Thermal Dispersion Flow Meters, Flow Switches & Controllers

Flow Meters for Cryogenic Fluids Flow Measurement

Mechanical Oil Flow Meter vs Digital

How Is an Ultrasonic Flow Meter Used for Leak Detection?

Case Sharing: Vortex Flow Meter for High-temperature Air

Guide to Flow Measurement Devices: Types and Selection

Digital Diesel Flow Meter – Higher Accuracy With Signal Output

Our newly developed force-sensitive target flow meter combines novel sensor technology and modern digital technology. This target flow meter features the advantage of having no moving parts, a characteristic not found in traditional target flow meters, orifice plate flow meters, or vortex flow meters. At the same time, it boasts measurement accuracy comparable to positive displacement flow meters.

Sino-Inst is a manufacturer of target flow meters. We offer over 10 types of target flow meters. We have extensive experience in flow measurement and continuously provide flow solutions to our customers. If you have any questions regarding the selection, technology, or applications of target flow meters, please feel free to contact our Sino-Inst sales engineer.

Target Flow Meter - Strong Media Compatibility

A target flow meter is an instrument that measures flow rate by utilizing the pressure difference caused by the fluid passing through a target. Target flow meters are also known as drag force flow meters.

Product SKU: SI-3706 Target Flow Meter

Product Brand: Sino-Inst

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)