Liquid roots meter is a type of positive displacement flow meter. High-precision metering for continuous or intermittent measurement of flow in pipelines. It has the characteristics of high precision, good reliability, light weight, long life, easy installation and use, etc. It is a typical feature of a volumetric flow meter.

Liquid roots meter indicates cumulative flow and instantaneous flow on site, and is equipped with a transmitter and flow intelligent controller to achieve long-distance measurement and control. It is widely used in petroleum, chemical industry, aviation, navigation, gasoline, clear oil and other departments to accurately measure petroleum and petroleum products, chemical solutions and other fluids.

Application range

Liquid Roots Meter Technical Parameters

- Working pressure (MPa): 0.6, 1.0, 1.6, 2.5, 4.0;

- Working temperature: LL-AL series (-20℃~+60℃), LL-EL, LL (-40℃~+60℃). When there are special requirements, the heat sink can be designed to reach a high temperature (60℃~200℃);

- Accuracy levels: 0.5, 0.3, 0.2;

- Flow range: m³/h;

| Diameter mm | Liquid viscosity 2.0~150mpa.s | Liquid viscosity 0.6~2.0mpa.s | Liquid viscosity 2.0~150mpa.s | Liquid viscosity 0.6~2.0mpa.s | Liquid viscosity 2.0~150mpa.s | Liquid viscosity 0.6~2.0mpa.s |

| 15 | 0.3~3 | 0.6~3 | 0.6~3 | 0.8~3 | 0.8~3 | 1~3 |

| 25 | 0.6~6 | 1.2~6 | 1.2~6 | 1.5~6 | 1.5~6 | 2~6 |

| 40 | 1.6~16 | 3.2~16 | 3.2~16 | 4~16 | 4~16 | 5~16 |

| 50 | 2.5~25 | 5~25 | 5~25 | 6~25 | 6~25 | 8~25 |

| 65 | 6~50 | 12~50 | 12~50 | 15~50 | 15~50 | 20~50 |

| 80 | 6~60 | 12~60 | 12~60 | 15~60 | 15~60 | 20~60 |

| 100 | 10~100 | 20~100 | 20~100 | 25~100 | 25~100 | 33~100 |

| 150 | 25~250 | 50~250 | 50~250 | 60~250 | 60~250 | 80~250 |

| Accuracy | 0.5 | 0.3 | 0.2 | |||

Main structural materials and nominal pressure:

| Model | Shell, front cover, back cover | Cover plate | waist wheel rotor | shaft | Shaft sleeve | Nominal pressure (MPa) |

| LL-AL | cast iron | cast iron | Aluminum alloy | Stainless steel | Ball/Ceramic Bearings | 0.6、1.0、1.6 |

| LL-EL | cast steel | cast iron | Aluminum alloy | Stainless steel | Ball/Ceramic Bearings | 2.5、4.0 |

| LL-LL | Aluminum alloy | cast iron/stainless steel | Aluminum alloy | Stainless steel | Ball/Ceramic Bearings | 0.6、1.0、1.6 |

| Note | Special parameters can be specially designed | |||||

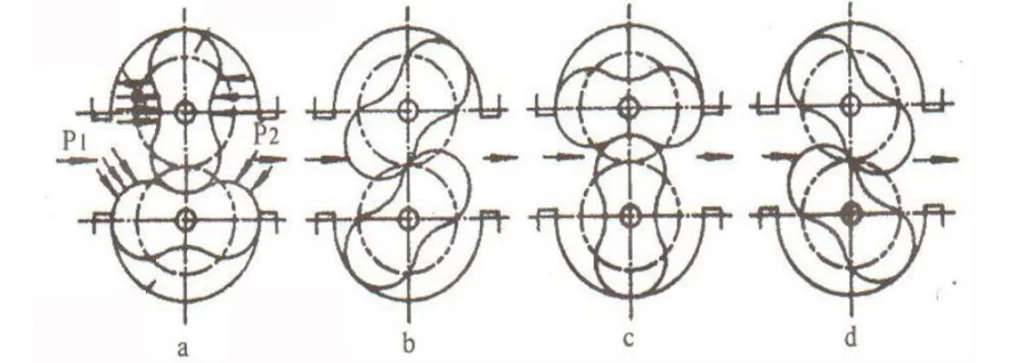

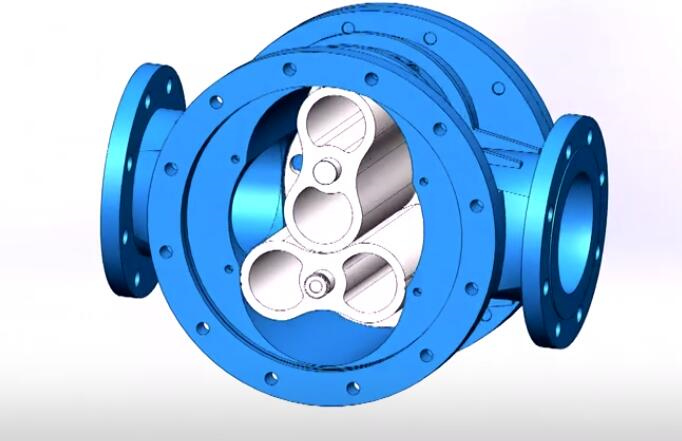

Liquid meter roots working principle

When the measured liquid flows through the measurement chamber, a pressure difference is formed at the inlet and outlet of the flow meter, and the waist wheel rotates driven by this pressure difference. At the same time, the two waist wheels are kept rotating continuously through a pair of driving gears fixed on the waist wheel shaft.

As the waist wheel rotates, the liquid is continuously discharged from the flow meter through the metering chamber. The amount of liquid flowing through each pair is four times the volume of the measuring chamber. Through the sealed coupling and deceleration mechanism, the number of rotations is decelerated and transferred to the counter. The counter indicates the instantaneous flow rate and cumulative flow rate of the liquid.

Installing a transmitter in the counter mechanism creates a waist wheel flowmeter with a transmitter. Matched with display instruments or microcomputer systems, it can realize automatic measurement and control of remote transmission (quantitative, cumulative, instantaneous and other functions). Instructions for use can also be found in the display instrument classification instructions.

Installation and use of Liquid roots meter

- A filter should be installed in front of the flow meter, and the arrows on the two meter bodies point in the same direction as the flow;

- When the liquid being measured contains gas, a gas separator should be installed in front of the flow meter;

- Regardless of whether the pipeline is installed vertically or horizontally, the waist wheel axis of the flow meter should be installed in a horizontal position (that is, the dial should be vertical to the ground);

- When the flow meter is installed correctly, if it is difficult to see the reading clearly, the counter can be rotated 180 degrees or 90 degrees;

- The throttle valve should be installed at the inlet of the flow meter, and the opening and closing valve should be installed at the outlet. When using the opening and closing valve, start it slowly and do not open the valve suddenly;

- It is strictly prohibited to use line sweeping steam to pass through the flow meter;

- In the continuous use department, the flow meter needs to be added with a bypass pipe;

- Before installing the flow meter, the pipeline needs to be flushed. During flushing, use a straight pipe section (in place of the flow meter) to prevent welding slag, debris, etc. from entering the flow meter;

- It is strictly forbidden to use water to calibrate flowmeters made of cast iron or cast steel;

- When using the flow meter, the flow rate must not exceed the technical requirements. The flow meter should work normally at 70~80% of the maximum flow rate;

- If the liquid to be measured is chemically corrosive, a flow meter made of stainless steel must be selected. If the liquid to be measured is highly corrosive, a flow meter made of 0Crl8Ni12MO2Ti must be selected.

More Featured Volumetric Flow Meters

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Top 3 Flow Meters for Oil

- Electromagnetic High Pressure Flowmeter | 0.6MPa-1.6MPa-6.3MPa-16MPa-25MPa-35MPa-42MPa

- Industrial Water Pressure Sensors | Selection Guide

- How to calibrate a pressure transmitter? How often?

- 10 Point Guide! Selection of Pressure Transmitters

- Checklist: Vortex Flow Meter Advantages and Disadvantages

- Application of Electromagnetic Flowmeter in Paper Mill Slurry Wastewater Treatment System

- Oval Gear Flow Meters with Better Price |Advantages and Disadvantages

- Brewery Flow Meters for Beer and Wine | Electromagnetic and More

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Target Flow Meter Advantages And Disadvantages and Featured Applications

- Magnetic Flow Meter Troubleshooting| Manufacturer’s Guide

- What Is Turbine Flow Meter K Factor?

- Ultra Low-Micro Liquid Flow Measurement

- Use and Maintenance of Coriolis Mass Flowmeters

- Vortex Flow Meters for Natural Gas

- What Is the Flow Rate? Velocity vs Flow

- Insertion type flow meters

- Orifice Plate Installation Guidelines

- Installation Instructions for Electromagnetic Flowmeters

- Water Flow Measurement Solution-Ultrasonic Flowmeter

- Slurry & Sludge Flow Measurement

- High-Pressure Flow Meters

- Cooling Water Flow Measurement

- Industrial Nitrogen Flow Meters

- Industrial Nitrogen Gas Flow Meters

- Industrial Liquid Nitrogen Flow Meters

- Flowmeters for Cryogenic Fluids Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Inline Compressed Air Flow Meters

- High Viscosity Flow Meters

- Diesel Flow Meter

Liquid roots meter is a high-precision meter used for continuous or intermittent measurement of flow in pipelines. It can indicate cumulative flow and instantaneous flow on site, and is equipped with a transmitter and flow intelligent controller to achieve long-distance measurement and control.

Our Sino-Inst Liquid roots meters are widely used in petroleum, chemical industry, electric power, metallurgy, transportation, commercial trade and other departments for accurate measurement of oil and petroleum products, chemical solutions and other fluids. If you need to purchase Liquid roots meters or have related technical questions, please feel free to contact us.

Liquid Roots Meter - Aviation, Marine, Oil System Flow Meter

Liquid roots meter is a type of positive displacement flow meter. High-precision metering for continuous or intermittent measurement of flow in pipelines. It has the characteristics of high precision, good reliability, light weight, long life, easy installation and use, etc. It is a typical feature of a volumetric flow meter.

Product SKU: Liquid Roots Meter - Aviation, Marine, Oil System Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 699

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)