A positive displacement flow meter is an instrument that accumulates flow directly based on the volume of discharged fluid or gas. Mechanical measuring elements are used to continuously divide the fluid into individual known volume parts. The total volume of fluid is measured based on the number of times the measuring chamber is repeatedly filled and drained of that volume fraction of fluid. Positive displacement flowmeter is referred to as PD flowmeter, which is a type of flow meter with higher accuracy.

- Ideal for low flows, and flow measurements involving starts and stops or pulses.

- Instead of the gears driving the fluid, the fluid drives the gears.

- No direct upstream and downstream piping is required during installation.

- Specifically designed for accurate measurement of thicker fluids such as resins, polyurethanes, adhesives, paints and various petrochemicals.

- The traditional positive displacement flowmeter uses a pointer indication and does not require a power supply; an electronic display can be added to support customization of pulse, 4-20mA, RS485 and other signal outputs;

positive displacement flow meter working principle

Positive displacement flow meter measurement uses a fixed small volume to repeatedly measure the volume of fluid passing through the flow meter.

Therefore, there must be a space that constitutes a standard volume inside the positive displacement flow meter, which is usually called the “measurement space” or “measurement chamber” of the positive displacement flow meter. This space is composed of the inner wall of the instrument housing and the rotating parts of the flow meter.

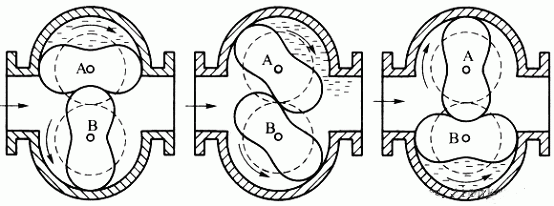

The working principle of Positive displacement flow meter is: when the fluid passes through the flow meter, a certain pressure difference will be generated between the inlet and outlet of the flow meter. The rotating part of the flow meter (referred to as the rotor) rotates under the action of this pressure difference and discharges the fluid from the inlet to the outlet. In this process, the fluid fills the “metering space” of the flow meter again and again, and then is continuously sent to the outlet.

Under given flow meter conditions, the volume of the metering space is determined as long as the number of rotations of the rotor is measured. The cumulative value of the fluid volume passing through the flow meter can be obtained.

positive displacement flow meter advantages and disadvantages

Advantages of positive displacement flow meter:

- High measurement accuracy.

- The installation pipeline conditions have no impact on the measurement accuracy, and there is no need for straight pipe sections.

- Can be used for measuring high viscosity liquids.

- Wide range.

- The direct-reading instrument can directly obtain the cumulative total without external energy, which is clear and easy to operate.

- Can be configured with an electronic display that supports pulse, current 4-20mA, RS485 and other signal outputs.

- Can be customized for ultra-high and low-temperature applications.

Disadvantages of positive displacement flow meter:

- The structure is complex and the volume is huge.

- The type, diameter, and working status of the medium to be measured have great limitations.

- Most meters are only suitable for clean single-phase fluids.

- Produce noise and vibration;

- Not suitable for liquids with foreign matter and low viscosity (above 1CP);

- Bearings are prone to wear and require regular inspection.

positive displacement flow meter types

Positive displacement flow meters can be classified according to measuring components.

Common types include the following:

- Oval gear

- Helical gear

- Spur gear

- Reciprocating/oscillating piston

- Multi-piston

- Nutating plate/disk

- Rotary vane/sliding vane

- Bi-rotor and tri-rotor

Featured Oval Gear Flow Meters

Read more about: Oval Gear Flow Meters Advantages and Disadvantages

Featured Spur Gear Flow Meters

Spur gear transmitters can measure very small flows and quantify small volumes of liquid. Compared with oval gear flow meters, GF Series Gear Flow Meter has more advantages in measuring micro flow.

There are aluminum alloy material, stainless steel material. Hydraulic oil, diesel oil, and even high viscosity fluids can be measured. There is a new type of PTFE material, which can withstand hydrofluoric acid, 98% sulfuric acid, nitric acid, hydrochloric acid , etc.

Featured Special Rotor/Gear PD Flow Meters

Flowmeter Selection Guide | Find the Best One for Your Application

Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

Volumetric Flow Meters: Comprehensive Guide and Product List

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Application of Electromagnetic Flowmeter in Paper Mill Slurry Wastewater Treatment System

Brewery Flow Meters for Beer and Wine | Electromagnetic and More

Need help ? Contact us now.

We will offer you the suitable Flow Measurement Solutions !

-1.jpg)