Industrial oils are the lifeblood of industrial development. Their applications are extremely wide-ranging, found in steel mills, military industries, hydraulics, machinery manufacturing, semiconductors, optics, metallurgy, power, railways, and many other sectors. Commonly used types include spindle oil, turbine oil, hydraulic oil, grinding oil, gear oil, turbine oil, rust preventative oil, cleaning oil, transformer oil, drawing oil, diesel oil, and kerosene.

Sino-Inst provides solutions for various parameter monitoring of industrial oils, including: oil pressure monitoring, oil temperature monitoring, oil flow monitoring, oil level monitoring, and oil density monitoring.

Characteristics of Industrial Oils

Flammability and Combustibility: Most mineral-based industrial oils (such as lubricating oils, hydraulic oils, and fuel oils) are hydrocarbons, belonging to Class C or Class B flammable/flammable liquids.

Volatility and Oil Mist Generation: Oils evaporate slowly at room temperature, but easily form oil mist or oil vapor under high-speed mechanical operation (such as gearboxes and high-speed spindles) or high-temperature environments.

Lubricity: Oils can form a stable adsorption or reaction film on friction surfaces, effectively reducing wear, frictional resistance, and energy consumption.

Thermal Stability and Thermal Conductivity: Oils need to remain stable within a certain temperature range. They may crack or oxidize at high temperatures; at low temperatures, viscosity increases dramatically, and fluidity decreases. Oils also play an auxiliary role in heat dissipation and heat transfer.

Compatibility and Material Adaptability: Oils have compatibility issues with sealing materials, coatings, and metals in equipment. Incorrect oil selection may lead to seal expansion/contraction, coating dissolution, and metal corrosion, causing equipment failure.

Therefore, when selecting sensors for oil-based media, we need to pay attention to details such as explosion-proof properties, viscosity, and temperature.

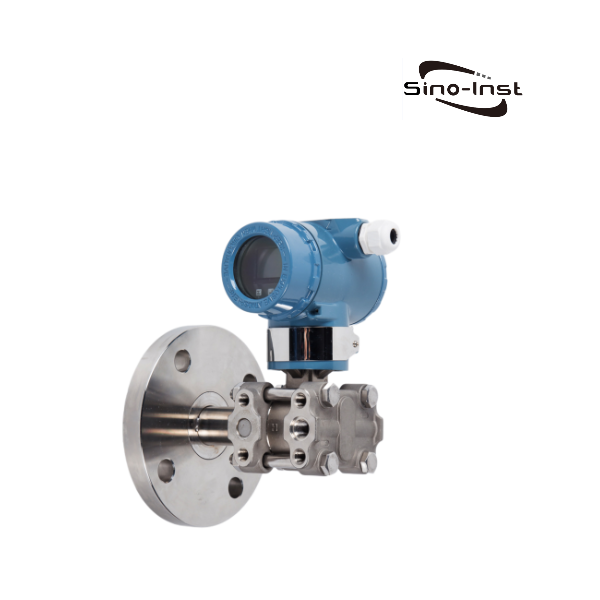

Oil Pressure Sensors

Oil pressure sensors are devices that measure oil pressure in real time and convert it into a local display or signal output. Stability and safety are the primary considerations for oil pressure sensors. Our Sino-Inst oil pressure sensors have Exd/Exia explosion-proof certification and stable measurement performance. We also support customization of parameters such as pressure range, temperature, and installation method. High temperatures up to 1200℃ and high pressures up to 1000MPa can be measured. Other parameters such as integrated temperature and pressure measurement, dynamic measurement, high-frequency output, and flange mounting can also be customized.

- How to Choose the Right Oil Pressure Transmitter for Your Application

- An All-inclusive Guide on Crude Oil Measurement

Oil Temperature Sensors

Through precise temperature sensors and measurement technology, oil temperature sensors can monitor real-time temperature changes in oil and provide accurate temperature data. By using oil temperature sensors, users can optimize liquid operating conditions, improve equipment reliability and efficiency, extend equipment lifespan, and ensure safe and efficient production.

Oil temperature sensors have wide applications in various industrial fields, providing users with an important means of temperature control and promoting the stability and sustainable development of production processes.

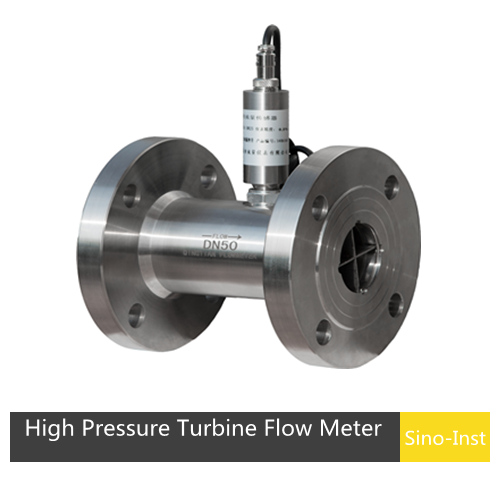

Oil Flow Meters

In the production, transportation, trade, and consumption of industrial oils, oil flow monitoring is required at each stage. Oil flow meters monitor flow rate changes by detecting the flow velocity and volume of the oil and converting it into readable electrical or digital signals. Examples include diesel, gasoline, crude oil, fuel oil, edible oil, heating oil, vegetable oil, heat transfer oil, lubricating oil/hydraulic oil, etc.

Sino-Inst supplies a variety of mechanical and digital oil flow meters, including:

- Turbine flow meters;

- High-temperature turbine flow meters;

- High-pressure turbine flow meters;

- Elliptical gear flow meters (cast iron, cast steel, stainless steel);

- Mass flow meters;

- Target flow meters, etc.

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Importance of Digital Fuel Flow Meters and Fuel Oil Flow Meters in Modern-day Industrial Applications

- Mechanical Oil Flow Meter vs Digital

- Industrial Hydraulic Flow Meters | Mechanical & Digital

- Top 3 Flow Meters for Oil

Oil Level Meters

Industrial oils are typically stored and used in tanks, such as diesel storage tanks and crude oil tanks. These tanks can sometimes be tens of meters in size. We generally need to monitor the oil level in these tanks in real time, and level control may be required.

For real-time oil level monitoring, contact or non-contact level meters can be selected. The level value is displayed locally, and a 4-20mA signal is output.

For oil level control, suitable single-point or multi-point level switches can be selected. These output relay or other switching signals.

- Single & Multi Liquid Level Float Switches – Effective Level Control

- Understanding Liquid Level Measurement: Types, Uses and Best Technologies

- Ultrasonic Level Transducer: Working Principle,Types and Benefits

- Float Type Level Transmitters for Continuous Level Measurement

Oil Density Meters

Density is one of the important indicators for measuring oil quality. Accurately measuring oil density allows us to determine its composition and purity, and thus whether it meets the prescribed quality standards and requirements.

Generally, different methods can be used to measure oil density, such as float-type densitometers, digital densitometers, and densitometer measurement systems.

Sino-Inst primarily supplies tuning fork vibrating densitometers and Coriolis mass flow meters, which measure both density and mass flow rate.

Cases Share

Case Study – Implementing Four-Point Liquid Level Control Using a Float Level Switch

Case: Non-Contact Material Level Measurement – Radar Level meter

Case: Rotary Paddle Level Switch For Material Level Control

Gravity Flow Meters for Diesel/Fuel Feed

High-Temperature Media Pressure Measurement Case: 900-1200°C

Case Sharing: Explosion-Proof Ultrasonic Level Meter

Customer Case: Customized DN10 Flow Meter for Petrol

Customized Case: High Temperature and High Pressure Pressure Measurement -100MPa-700℃

If you are still unsure how to choose the right measuring instrument for your oily media, please contact our sales engineers.

-1.jpg)