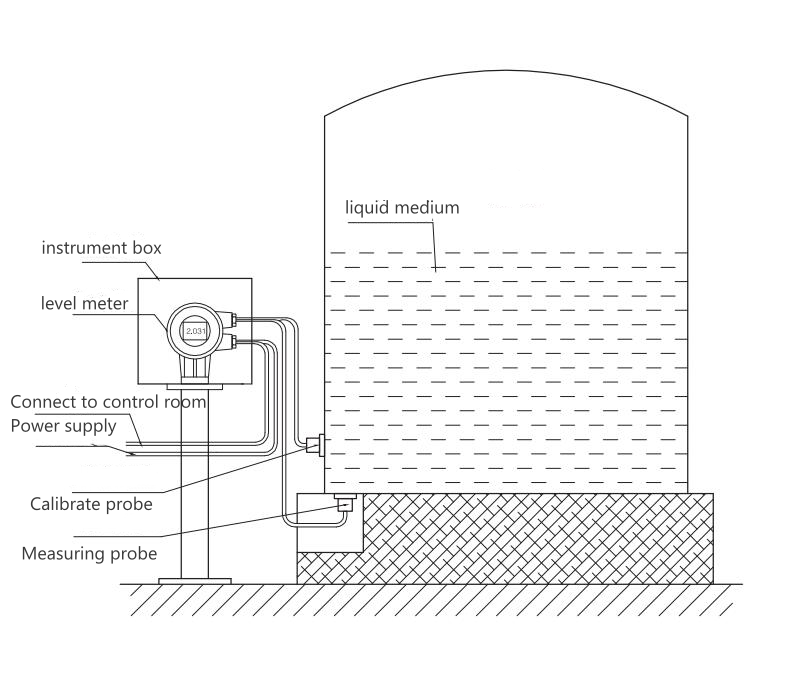

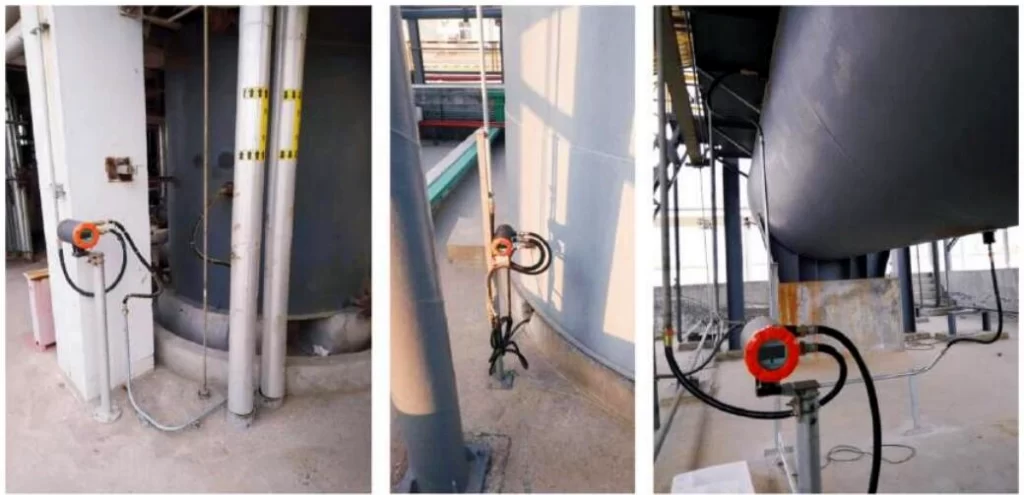

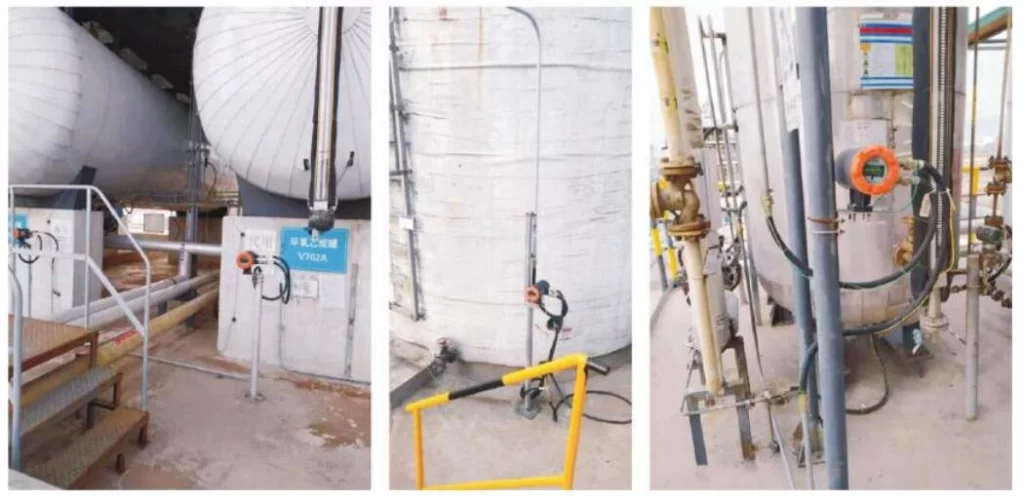

The External Ultrasonic Level Meter enables truly non-contact measurement of liquid levels in closed containers. The ultrasonic sensor (probe) is installed just below (bottom) the outer wall of the container being tested. There is no need to drill holes in the container being tested. It is easy to install and does not affect production.

The External Ultrasonic Level Meter can accurately measure the liquid levels of various toxic substances, strong acids, strong alkalis and various pure liquids in high-pressure sealed containers. External Ultrasonic Level Meter has no special requirements for the material of liquid medium and container, and adopts explosion-proof design to meet explosion-proof requirements.

Features

External Ultrasonic Level Meter technical parameters

| Type | Two-wire system | Four-wire system | Intrinsically safe |

| measurable range | 3m, 5m, 10m, 20m, 30m | ||

| Measurement error | 1‰~1% (too thick tank wall, pressure, and temperature changes can affect accuracy) | ||

| display resolution | 1mm | ||

| Measurable wall thickness | 2~70mm | ||

| Power supply | DC24V | ||

| Signal output | Analog output: 4~20mA, maximum load 750Ω | ||

| Communication Interface | RS485/MODBUS/HART communication protocol | / | |

| Debug interface | infrared | ||

| power | 10w | 1w | |

| shell | Material: cast aluminum alloy | ||

| Protection level | IP67 | ||

| Explosion-proof signs | ExdllCT6 Gb | ExiallB T5Ga | |

| environment humidity | 15%~100%RH | ||

| Host applicable ambient temperature | -50℃ to +70℃ | ||

| Ultrasonic probe operating temperature | Normal Temperature: -50℃~+70℃, high temperature probe temperature can reach 100℃ | ||

| Host dimensions | Length 160mm* Width 228mm* Height 180mm | ||

| Host weight | 3.4KG | ||

Application and installation conditions

Media purity

- The liquid cannot be filled with dense air bubbles;

- A large amount of solids, such as crystals, cannot be suspended in the liquid;

- There should not be a large amount of sediment deposited on the bottom of the tank.

Measurable container

Material: carbon steel, stainless steel, various metals, fiberglass, epoxy resin, hard plastic, ceramics, glass, hard rubber and other materials or; composite materials

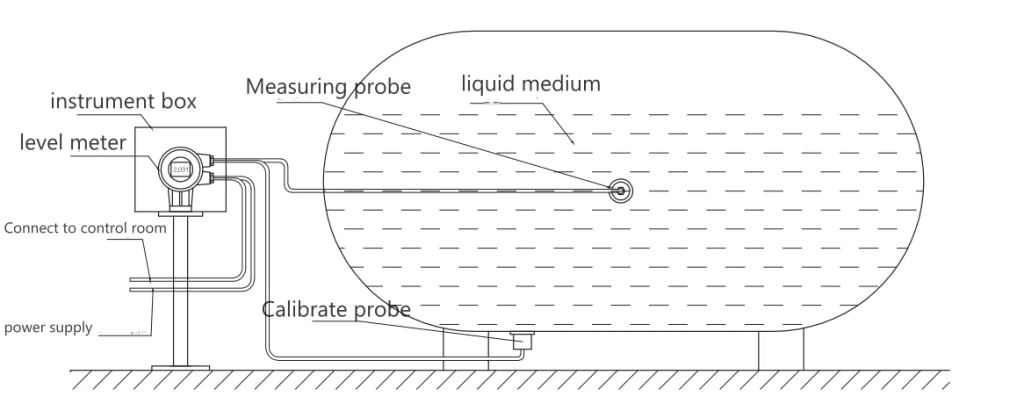

Tank type: spherical tank, horizontal tank, tank tank, vertical tank, etc.;

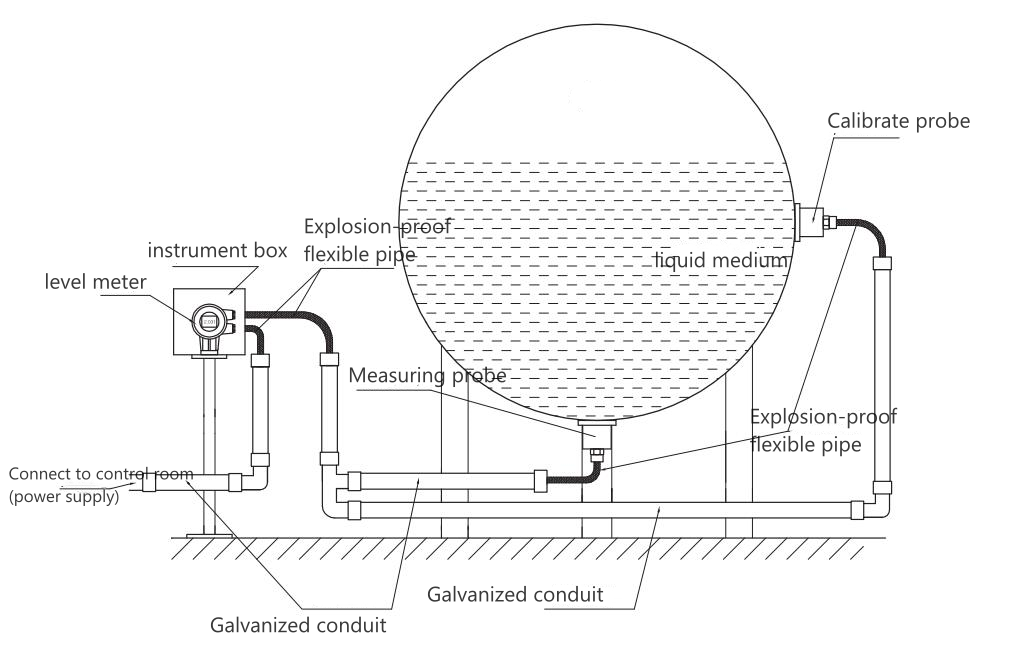

Probe installation requirements

- There are no obstructions such as coils directly above the probe.

- The probe is higher than the sewage outlet.

- Keep the probe away from the liquid inlet at the bottom of the tank, and the probe away from the top of the tank! Below the liquid inlet.

- When the liquid level measurement probe is installed using magnetic/link fixing methods, the size of the installation surface on the container wall should be no less than a Φ100mm round surface. The surface roughness should reach 1.6. The inclination should be less than 3° (except for bypass pipes).

External Ultrasonic Level Meter Working Principle

External Ultrasonic Level Meter f adopts the principle of intra-acoustic echo ranging, which overcomes the impact of the tank wall on the transmission of ultrasonic signals. Using advanced digital signal processing technology, it can truly achieve non-contact, high-precision measurement of the inside of the tank. liquid level.

External Ultrasonic Level Meter f can output 4~20A standard signals or output measurement results to a host computer (or secondary meter) through the RS-485 interface to meet the automatic control of the system.

Application Industry

Applicable Media

| C3 | Butadiene | polyethylene |

| Ammonia mother liquor | xylene | sulfuric acid |

| Ammonia | dimethyl ether | chlorobenzene |

| acetone | gasoline | Methyl chloride |

| Acrylic | Trifluoroethylene | vinyl chloride |

| diesel fuel | Toluene | kerosene |

| nitrogen methyl | Methanol | Concentrated sulfuric acid |

| aniline | Liquefied carbon dioxide | Trimethylhydrazine |

| Butane | Liquefied hydrocarbons | Light hydrocarbons |

| Aromatic hydrocarbons | Ether | hydrofluoric acid |

| phenolic water | Ethane | Tetrachlorethylene |

| hydrogen fluoride | Ethylene | amyl acetate |

| Freon | Isopropylene | anhydrous hydrogen fluoride |

| Propylene oxide | Isobutane | Nitric acid |

| Ethylene oxide | Isobutylene | Bromine |

| Methylamine | raw oil | hydrochloric acid |

| Methyl tert-butyl ether | n-butane | liquid ammonia |

| formaldehyde | vegetable oil | Liquefied gas |

| Alcohol | ethanol | liquefied petroleum gas |

| liquid chlorine |

More Featured Level Measurement

The External Ultrasonic Level Meter adopts a non-contact measurement method with the sensor attached externally and the liquid being measured, achieving truly completely isolated measurement. The External Ultrasonic Level Meter can continuously measure the liquid level outside the tank without drilling holes or igniting the tank, enabling non-stop installation.

It is especially suitable for accurate measurement of the liquid levels of various toxic substances, strong acids, strong alkali and various pure liquids in closed containers. External Ultrasonic Level Meter adopts explosion-proof design and is widely used in explosion-proof situations.

We, Sino-Inst, manufacture and supply various types of ultrasonic level Meter, explosion-proof ultrasonic level meter, portable ultrasonic level indicator, etc. If you need to purchase Ultrasonic Level Meter or have related technical questions, please feel free to contact us.

External Ultrasonic Level Meter for Liquid Tanks | Sino-Inst

The External Ultrasonic Level Meter enables truly non-contact measurement of liquid levels in closed containers. The ultrasonic sensor (probe) is installed just below (bottom) the outer wall of the container being tested. There is no need to drill holes in the container being tested. It is easy to install and does not affect production.

Product SKU: External Ultrasonic Level Meter for Liquid Tanks

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 3600

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)