The magnetostrictive level transmitter is a new type of liquid level measuring instrument used for continuous measurement of liquid level and interface. Measuring range: 0.2m~23m; accuracy optional: ±1mm, ±5mm, ±1cm, ±2cm, ±5mm.

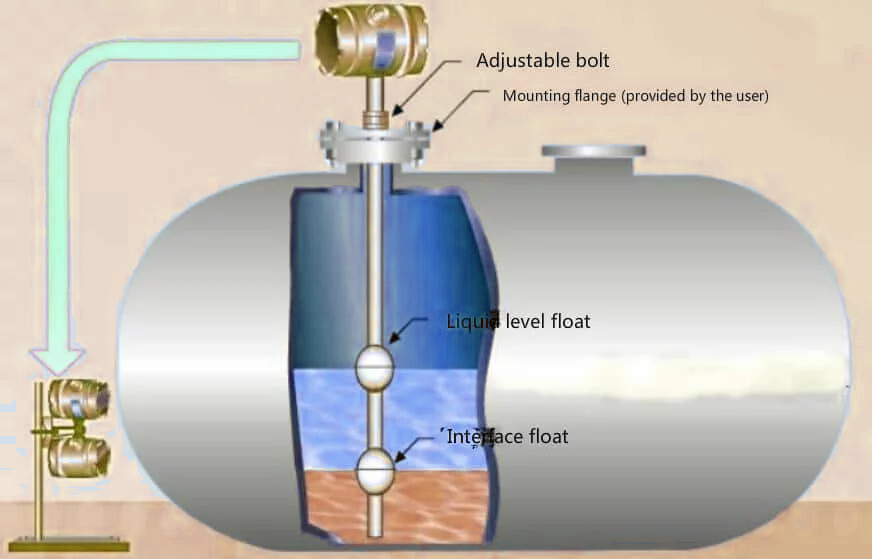

Our Sino-Inst magnetostrictive level transmitter can provide two independent outputs: one, interface; two, overall level. It can be applied when the specific gravity difference is reduced to 0.02. Commonly used for measuring oil-water interfaces, and others including acid tanks, propane containers, desalters and sewage tanks.

Features

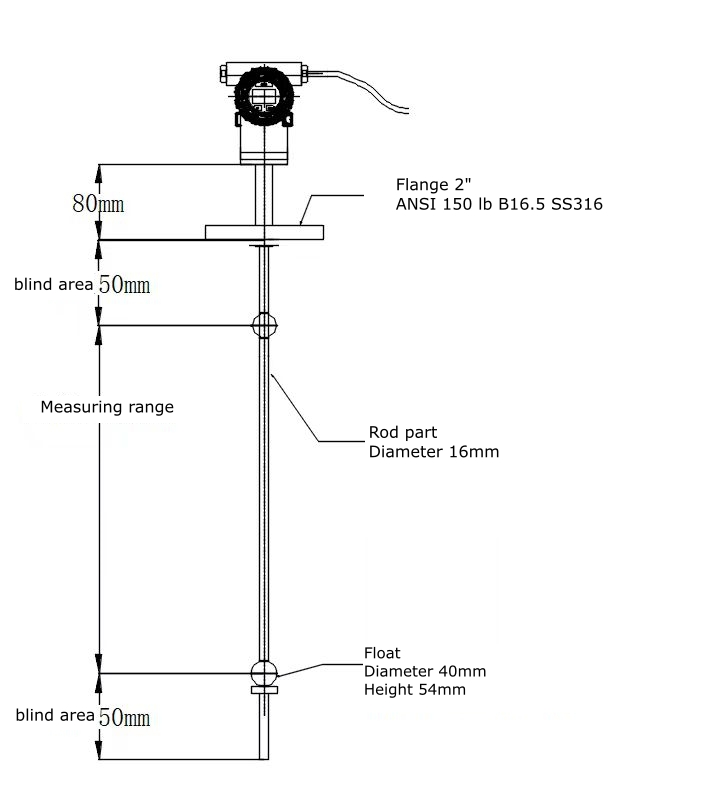

Structure of Magnetostrictive Level Transmitter

Magnetostrictive Level Transmitters are divided into three series: flexible probe rod type, hard probe rod type, and external float isolation detection series. The meter body contains two main parts: the electronic part and the sensing part.

Sensing part (probe):

The probe rod is 5/8” in diameter and has a sealed end. The interior of the probe rod is hollow and contains precision magnetostrictive wire.

In addition to the magnetostrictive wire, the probe rod can also be equipped with up to 8 RTD temperature sensors for temperature detection.

The maximum length of the probe rod can be 23 meters, and all probes above 6 meters adopt a flexible cable structure.

Electronic part (i.e. transmitter):

The shell is made of aluminum alloy or 304 stainless steel, and is double-chamber type (that is, the transmission part and the wiring part are separated). One cavity contains the microprocessing module and circuit board. The microprocessing module has operating buttons, and the other cavity contains the binding posts.

There is a wire connecting the circuit board to the probe processing board.

Technical Parameters

| Item | Parameter |

| Applicable media | Suitable for level measurement of clean liquids such as water, oil, ethanol, etc. |

| Power supply | 24V±2.4VDC/220V |

| Operating temperature | -40℃-320℃ |

| Humidity limits | SAMA |

| Pressure limit | 2000psi |

| Maximum range | 0.3m~18.1m |

| Temperature output | 0-8 temperature point output (optional) |

| Output form | 4~20mA, 0~5V, HART, RS-485 |

| linear error | Better than ±0.02%FS; |

| Output temperature drift | 50ppm/℃ |

| Product power consumption | ≤50mA |

| Output ripple | ≤20MV |

| Display type | LCD display/without display |

| load capacity | 4~20mA output: load capacity ≤500Ω; 0~5V output; controller load ≥5KΩ |

| Rod material | 0Cr18Ni9Ti, 1Cr18Ni9Ti, PTFE lined |

| Electronic compartment shell | 1Cr18Ni9Ti or aluminum explosion-proof shell. |

| Lead method | a. Shielded cable connection, b. Aviation plug connection c.Terminal connection |

| Explosion-proof certification | ExdIIBT5, ExiaIIBT5, ExdIICT5 |

| Protection level: | IP65 |

| Polarity protection | Diodes are connected in series in the loop |

| Diagnosis | Online diagnosis via HART protocol or AMS protocol, |

Magnetostrictive Level Transmitter working principle

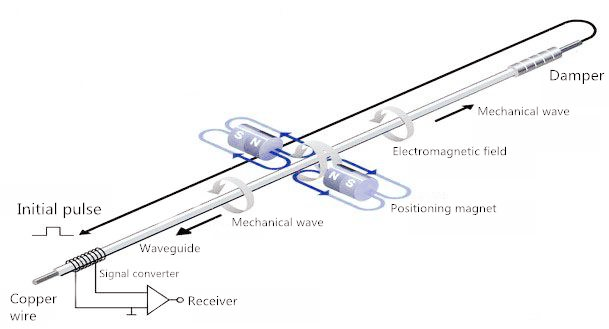

The magnetostrictive liquid level/interface level transmitter is designed using the principle of magnetostriction, a physical phenomenon.

The specific working principle is as follows:

A fine magnetostrictive wire is installed in a non-magnetic sensing tube. One end of the magnetostrictive wire is connected to a piezomagnetic sensor. The piezomagnetic sensor sends 10 current pulse signals to the magnetostrictive wire every second. And timing. The current pulse is transmitted downward along the magnetostrictive line, generating a downward-moving ring magnetic field.

The annular magnetic field interacts with the magnetic field of the magnetic float, generating a torsional stress wave on the magnetostrictive line. This torsional stress wave travels from the position of the float to the upper and lower ends along the magnetostrictive line at a known speed. It is known that Until the piezomagnetic sensor receives this torsional stress wave signal.

The time interval between the initial current pulse wave and the return torsional stress wave can be known through the timing circuit. The position of the float can be determined based on the time interval. Since the float always floats on the liquid surface, the liquid level can be accurately determined s position.

Magnetostrictive Level Transmitter Advantages and Disadvantages

Featured Applications

Magnetostrictive level transmitter is suitable for continuous measurement of liquid level and interface.

More Industrial Level Transmitters and Measurement Solutions

In industrial production, the control and detection of liquid level is very important, especially in storage tanks. Magnetostrictive Level Transmitter, as a liquid level gauge widely used in storage tanks, has the advantages of high accuracy, strong reliability, and long service life. It has become one of the standard equipment for liquid level detection in storage tanks.

Our Sino-Inst’s Magnetostrictive Level Transmitter supports customization of various measurement parameters, temperature, pressure, range, output, etc. In addition to Magnetostrictive Level Transmitter, we also provide ultrasonic, radar, hydrostatic pressure and other liquid level meters. If you need to purchase Magnetostrictive Level Transmitter, or need to measure liquid level, interface, etc., please feel free to contact us!

Magnetostrictive Level Transmitter for Sale| 0.2m~23m

Magnetostrictive Level Transmitter for liquid level and interface measurement. Optional temperature output. Range: 0.2m~23m; accuracy: ±1mm, ±5mm. Best price!

Product SKU: Magnetostrictive Level Transmitter | High Accuracy 0.2m~23m

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 690

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)