The turbine flow meter is a digital diesel flow meter that provides real-time inline monitoring of instantaneous and cumulative diesel flow.

The diesel flow meter uses a Turbine to measure. It first converts the flow rate to the speed of the turbine. And then converts the speed into an electrical signal that is proportional to the flow. This flow meter is used to detect the instantaneous flow and the total accumulated flow. Its output signal is frequency, which is easy to digitize.

Diesel Turbine Flow Meter Specs

Diesel Flow Meter is one type of Liquid Turbine Flow Meter.

- Meter Diameter:

Threaded connection: DN 4, 6, 10, 15, 20, 25, 32, 40

Flange connection: DN(15, 20, 25, 32, 40) 50, 65, 80, 100, 125, 150, 300

Plug-in: DN 200 or more - Range ratio: 1:10; 1:15; 1:20

- Instrument material: 304 stainless steel, 316 (L) stainless steel, etc.

- Medium temperature: -20 ℃ ~ + 120 ℃

- Ambient temperature: -10 ℃ ~ + 55 ℃

- Relative humidity: 5% -9%

- Atmospheric pressure: 86 ~ 106Kpa

- Sensor Output signal: pulse frequency signal, low level ≤0.8V high level ≥8V

- Transmitter Output signal: Two-wire 4-20mA current signal

- Sensor Power supply: + 12VDC, + 24VDC (optional)

Transmitter Power supply: + 24VDC - On-site display type: the instrument comes with a lithium battery

- Explosion-proof form: Basic type non-explosion-proof, explosion-proof type

- Protection level: IP65, IP67

Features

Applications

- Suitable for various nominal diameters. From DN15 ~ DN2000mm to larger;

- Suitable for high and low temperature media. From -50 ℃ ~ + 260 ℃ (special can be larger);

- Suitable for low, medium and high pressure working conditions. From 0 to 25MPa (specially larger)

- Fuel consumption

- Engine performance testing

- Engine time monitoring to pro-actively signal maintenance

- Real-time fuel monitoring and consumption reduction

- Fuel theft detection and prevention

Acceptable Liquids

Turbine Flow Meters are Widely used in:

Diesel, bio-diesel, kerosene, gasoline;

Petroleum, organic liquid, inorganic liquid;

Liquefied gas;

Alcohol;

Oil, DEF, heating oil, grease and certain chemicals;

low temperature fluid flow measurement.

What is a fuel flow meter?

Fuel flowmeter refers to the flowmeter used to measure the flow rate of fuel. Commonly referred to as turbine flow meters and oval gear flow meters.

A flow meter is used to measure the quantity of fluid that has been moved during the transfer process. They have a visual display, which can be either mechanical or digital, for the user to read off the measurement. Flow meters are used within a variety of fluid transfer applications. And therefore whilst they are always used to measure the fluid, the ways in which they work are slightly different.

Of course, the fuel flow meter also has some characteristics of its own, such as:

Explosion proof

Pulse output

Unaffected by changes in fluid density, viscosity, temperature, pressure, and conductivity.

If you need more accurate measurement, you can choose a mass flow meter. Coriolis mass flowmeters have zero drift but the impact is relatively small. Higher operating costs. Mass flow meters can measure temperature and density online. Oval gears are relatively stable for mechanical flow meters.

How Does a Fuel Flow Meter Work?

Diesel Flow Meter Working Principle

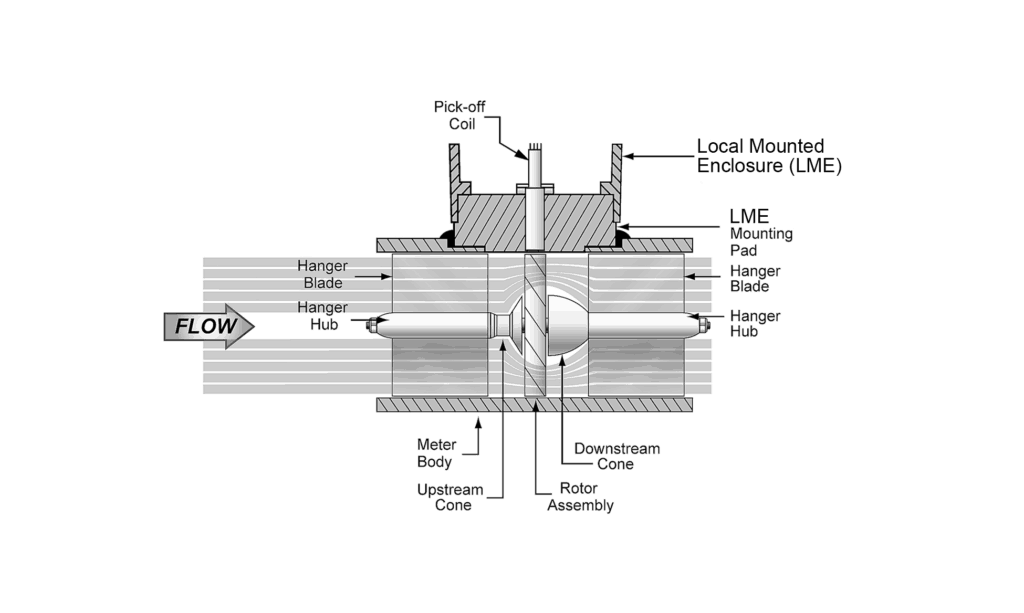

The working principle of the turbine flow meter:

- The working principle of the turbine flow meter:

- Fluid flows through the sensor housing.

- Because the blade of the impeller has a certain angle with the flow direction, the impulse of the fluid causes the blade to have a rotating moment.

- Blades rotate after overcoming frictional torque and fluid resistance.

- After the torque is balanced, the speed is stable.

- Under certain conditions, the speed is directly proportional to the flow rate.

- Because the blade is magnetically permeable, it is in the magnetic field of a signal detector (made of permanent magnetic steel and coils).

- The rotating blade cuts the magnetic field lines and periodically changes the magnetic flux of the coil.

- Thereby, an electric pulse signal is induced at both ends of the coil.

- This signal is amplified and shaped by the amplifier to form a continuous rectangular pulse wave with a certain amplitude.

- Remotely transmitted to the display instrument, show the instantaneous flow rate and cumulative amount of the fluid.

- In a certain flow range, the pulse frequency f is proportional to the instantaneous flow Q of the fluid flowing through the sensor.

Technology Guide to Turbine Flow Meters

Turbine Flow Meter Equation

And the flow equation is:

Q = 3600 × f / k

In the formula:

- f——pulse frequency [Hz];

- k——meter coefficient [1 / m] of the sensor, given by the checklist. If the unit is [1 / L]

- Q——the instantaneous flow of the fluid (in the working state) [m3 / h];

- 3600-conversion factor.

The meter factor of each sensor is filled in the verification certificate by the manufacturer.

The k value is set in the matching display instrument, and the instantaneous flow rate and cumulative total can be displayed.

Diesel Flow Meter Pulse Output

Diesel Flow Meter can have output types: Pulse, 4-20mA analog output, RS485 (Modbus-RTU protocol), and HART.

In electronic technology, a pulse signal is continuously emitted according to a certain voltage amplitude and a certain time interval. The time interval between pulse signals is called the period. And the number of pulses generated in a unit time (such as 1 second) is called the frequency.

Frequency is a measurement name describing the number of pulses that a cyclic signal (including a pulse signal) appears in a unit time. The standard measurement unit for frequency is Hz (hertz). The system clock in a computer is a typical pulse signal generator with a fairly accurate and stable frequency.

Frequency is represented by “f” in mathematical expressions, and its corresponding units are: Hz (hertz), kHz (kilohertz), MHz (megahertz), GHz (gigahertz). Its 1GHz = 1000MHz, 1MHz = 1000kHz, 1kHz = 1000Hz.

The time unit for calculating the pulse signal period and the corresponding conversion relationship is:

s (seconds), ms (milliseconds), μs (microseconds), ns (nanoseconds). Where: 1s = 1000ms, 1ms = 1000μs, 1μs = 1000ns.

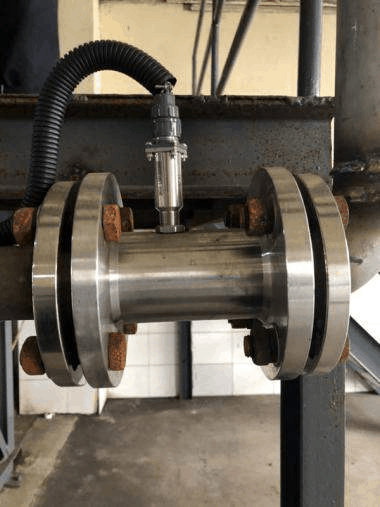

Inline Diesel Fuel Flow Meter

Typically, liquid turbine flow meters are used when measuring industrial diesel fuel flow. This is because they are inexpensive to purchase, offer high measurement accuracy, provide local digital display, and show instantaneous and cumulative flow rates in real time. They also support signal output. This essentially meets all the needs of industrial users for diesel fuel measurement.

Of course, customers can also choose oval gear flow meters. Especially in situations where there is no power supply, oval gear flow meters can be configured mechanically, requiring no external power. Measurement remains stable. However, oval gear flow meters require the measured medium to be clean and free of impurities.

Techincal Support

Digital Water Flow Meter

Digital water flow meter, is the electronic flow meter, which display the flow rate of water. Different Industrial liquid, different pipe for 1 inch, 2 inch, use different flow meters.

Steam Flow Meters

Steam flow meters are digital flow meters for steam flow measurement. A variety of technologies are suitable for steam flow measurement. Common types are: Vortex flow meter.

Natural Gas Flow Meter

Natural Gas Flow Meter, is the inline flow meter for natural gas pipeline. Like: thermal mass flow meter, ultrasonic natural gas flow meter, natural gas turbine flow meter. Intelligent Gas Precession Vortex Flowmeter, and differential pressure flow meter.

Sanitary Flow Meter

Sanitary Flow Meter, also called the tri-clamp flow meter. Sanitary Flow Meters have stainless steel bodies and come standard with Tri-Clover fittings. Sanitary flow meter meets the requirements of the food, and beverage company industries.

Turbine type flow meter

Turbine type flow meter is one type of mechanical flow meters. Turbine flow meter use the mechanical energy of the liquid to rotate a rotor in the flow stream. Turbine flow meters measure the velocity of a variety of liquids (oil, water), gases (natural gas) and vapors.

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes.

Water Flow Meter Types

Water Flow Meters are flow meters measure and show the flow rate of water flow. Water flow measurement is important for inductrial applications, like the wastewater treatment.

Sino-Inst is a Professional Diesel Flow Meter manufacturer and supplier. Sino-Inst offers over 10 fuel flow meter products. About 70% of these are turbine flow meters. Oval Gear flow meters are also widely used.

A wide variety of fuel flow meter options are available to you, such as free samples and paid samples. Sino-Inst’s fuel flow meters service for industrial applications, like: Industrial gas, corrosives and brine, chemical processing, energy, electronics, laboratories, medical, and many other industries.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Flow meter products are most popular in USA, Southeast Asia, Europe, and UK.

-1.jpg)