What is the turbine flow meter K factor? This question has garnered considerable attention. The K factor of a turbine flow meter is a coefficient that represents the ratio of the number of pulses in a high-frequency pulse signal to the volumetric flow rate.

The turbine flow meter K factor is fundamental data used in commercial flow meter calculations. Within the flow meter’s flow range, the meter factor is a fixed constant. Its value is determined by calibration. Each time a commercial flow meter is calibrated, the current meter factor is reported.

Importance of Turbine Flow Meter K Factor

The K-factor of a turbine flow meter plays an irreplaceable role in the operation of a flow meter. If the K-factor is set incorrectly or deviates, it will cause errors in the flowmeter’s output signal, affecting the accuracy and reliability of flow measurement. Therefore, the K-factor must be given due attention during the design, installation, commissioning, and maintenance of the flowmeter.

Accurate Measurement and Control:

The K Factor converts the actual flow rate into an instrument output signal (such as current, voltage, or pulses), enabling precise flow measurement and control. This is crucial for industrial processes requiring high-precision flow control.

Meeting Different Application Needs:

By adjusting the K Factor, you can calibrate and correct the flowmeter output signal to meet the flow measurement accuracy and range requirements of different applications.

Fault Diagnosis and Troubleshooting:

When a flowmeter malfunctions or inaccurate measurements occur, checking the K Factor can assist in troubleshooting and quickly identify the problem and implement appropriate solutions.

Calculation of Turbine Flow Meter K Factor

The relationship between the instrument factor K of a turbine flowmeter, the number of output pulses N, and the total fluid volume v flowing through it can be expressed by the following mathematical formula:

v = K * N / 1000

Where: v is the total fluid volume flowing through (unit: cubic meters), K is the instrument factor (unit: pulses/cubic meter), and N is the number of output pulses.

This formula indicates that when the instrument factor K of a turbine flowmeter is known, the total fluid volume v flowing through it can be determined by measuring the number of output pulses N.

The instrument factor K is an inherent parameter of the flowmeter and depends on factors such as the flowmeter model, size, fluid properties, and measurement conditions.

Read more about: Turbine Flowmeter Technology

The coefficient of the turbine flowmeter can be divided into two sections, namely the linear section and the nonlinear section.

The linear segment is about two-thirds the size of its working segment. Its characteristics are related to the sensor structure size and fluid viscosity.

In the nonlinear section, the characteristics are greatly affected by bearing friction and fluid viscous resistance.

When the flow rate is lower than the lower limit of the flow rate of the sensor, the meter coefficient changes rapidly with the flow rate.

Pressure loss and flow rate are approximately quadratic. When the flow exceeds the upper flow limit, care should be taken to prevent cavitation.

The shapes of the TUF characteristic curves with similar structures are similar, it differs only in the level of systematic error.

The characteristic curve of the turbine flowmeter is verified by the flow verification device, which does not ask the internal fluid mechanism of the sensor at all. The sensor is regarded as a black box, and its conversion coefficient is determined according to the input (flow rate) and output (frequency pulse signal), which is convenient for practical application.

However, it should be noted that this conversion factor (meter factor) is conditional. Its calibration conditions are reference conditions. If the use deviates from this condition coefficient will change, the change situation depends on the sensor type. It depends on the pipeline installation conditions and the physical parameters of the fluid.

The theoretical flow equation of the turbine flowmeter can obtain the motion equation of the impeller according to the momentum moment.

Turbine flow meters are a very important part of energy metering. Widely used in environmental protection, chemical industry, energy and many other fields. Some of our commonly used energy is measured by turbine flowmeters, which play an irreplaceable role in energy management and economic accounting.

Many manufacturers produce turbine flowmeters. Sino-Inst is a company specializing in the production of turbine flowmeters. Over the years, Sino-Inst has been working hard to improve the quality of turbine flow meters. Now that you know the coefficient k of the turbine flowmeter, you should know more about the turbine flowmeter.

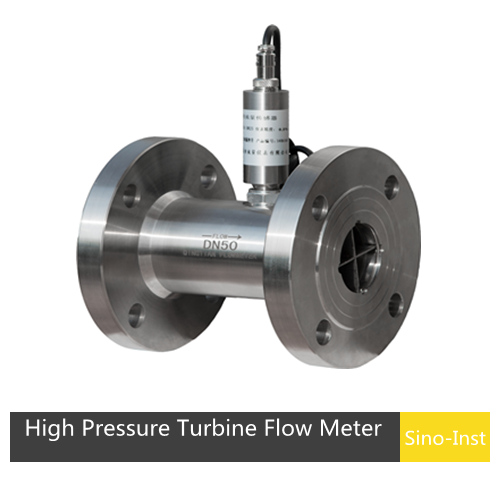

Featured Turbine Flow Meters

How do I know the K-factor of my flow meter?

The ideal flowmeter meter factor is a constant that depends solely on the instrument’s structural parameters and is typically determined through calibration. Each flowmeter has a unique meter factor, which guarantees its measurement accuracy.

In actual measurement, the meter factor is also affected by various factors, such as fluid viscosity, bearing damping, and lubricant viscosity. Therefore, in practical applications, flowmeters require regular calibration to ensure the accuracy and stability of their meter factors.

Sino-Inst flowmeters receive their K-factor values during their final calibration before leaving the factory. This K-factor is typically indicated on the stainless steel nameplate of most flowmeters.

More Flow Measurement Solutions

Besides turbine flowmeters, other types of flowmeters have K factors, such as vortex flowmeters and PD flowmeters. Understanding the K factor of a turbine flow meter can help you select, use, and maintain a turbine flow meter.

Turbine flowmeters use the mechanical energy of a fluid to rotate a rotor. Turbine flowmeters are the most commonly used devices for electronically measuring flow in pipelines. Sino-Inst’s turbine flowmeters are widely used as water, diesel, and gasoline flowmeters.

Sino-Inst’s flowmeters are manufactured in China and offer high quality and competitive pricing. They are widely used in China, India, Pakistan, the United States, and other countries. If you need to purchase a flowmeter or have any other technical questions about turbine flowmeters, please feel free to contact us.

-1.jpg)