Although digital oil flow meters are constantly being innovated, Mechanical Oil Flow Meters still occupy a large proportion of industrial oil flow measurement, including flow measurement of crude oil, fuel oil, diesel, edible oil, and other oils.

Positive displacement flow meter is a type of flow meter selected as Mechanical Oil Flow Meter. Including oval gear flow meter, spiral rotor flow meter, etc.

Importance of oil flow meter in industry

In today’s highly developed industrial field, oil flow meter is one of the indispensable key roles.

The importance of oil flow meter is first reflected in accurate measurement. In the petroleum, chemical and other industries, oil flow meter can measure the flow of oil in real time and accurately, providing key data support for the production process.

Oil flow meter can also help enterprises achieve efficient production management. Through continuous monitoring of oil flow, abnormal conditions in the production process can be discovered in time, such as excessive flow fluctuations, pipeline blockage, etc.

At the same time, based on accurate flow data, enterprises can carry out more scientific resource allocation and cost accounting.

In addition, oil flow meter is also of great significance for ensuring product quality. In some industrial productions with strict requirements on oil quality, stable flow control directly affects the quality of the final product.

Taking the fine chemical industry as an example, accurate oil flow control can ensure the consistency and stability of chemical reactions, thereby producing high-quality chemical products.

In the energy industry, oil flow meter plays a key role in the transportation and distribution of oil. It can help enterprises better manage the flow of energy. Improve energy efficiency and reduce energy loss.

In the field of environmental protection, oil flow meters can help monitor the discharge and treatment of oil products. Ensure that enterprises comply with environmental regulations and avoid environmental problems caused by inaccurate flow.

Industrial Oil flow meters can be divided into mechanical and digital types. Next, let’s look at their differences.

Mechanical Oil Flow Meter Working Principle

Mechanical oil flow meters operate on the Positive Displacement (PD) principle, which physically divides the fluid into discrete, known volumes. Unlike meters that estimate flow based on velocity, a PD meter captures a specific “pocket” of oil and moves it from the inlet to the outlet.

The core of this technology is the measurement chamber. As oil enters, it creates a pressure differential that forces the internal rotors to move. Since the volume between the rotors and the chamber wall is fixed, every rotation corresponds to a precise amount of liquid.

Depending on the specific application, there are three primary mechanical configurations:

- Oval Gear Flow Meter: This is the industry standard for diesel flow meters and lubricants. Two interlocking oval gears rotate, trapping a fixed volume of oil in the gaps.

- Roots Rotor Meter: Utilizing lobe-shaped rotors, these are ideal for high-volume flows where maintaining a low pressure drop is critical.

- Helical Variants: These use screw-like rotors to provide a smooth, continuous measurement, which is particularly effective for exceptionally thick or heavy oils.

Key Advantages of Mechanical Oil Flow Meters

Mechanical oil flow meters have the following main features:

Power independence:

Mechanical oil flow meters do not require an external power source to operate. This independence ensures that they can function even in remote areas or during power outages.

Durability and service life:

Mechanical oil flow meters can be made of cast iron, cast steel, stainless steel and other materials. They have a longer service life. They can even meet various conditions such as high temperature, high pressure, and low temperature.

Easy operation:

Mechanical flow meters have fewer electronic components and are simple to operate. The possibility of errors caused by electronic failure is reduced.

Cost-effectiveness:

Generally, the initial cost of mechanical oil flow meters is lower than that of digital flow meters. And the maintenance cost is low.

Wider range of applications:

For some special applications, especially industries and applications that handle high viscosity liquids, mechanical oil flow meters are more suitable than digital flow meters.

Tried and tested:

Mechanical flow meters have been around for quite some time. Making them reliable and efficient tools. Giving people confidence in their readings.

Mechanical Register and Totalizer Options

One of the biggest draws of a mechanical oil flow meter is the display. We provide several configurations based on how you track your data:

- Dual-Pointer Displays: Great for real-time monitoring of flow rates.

- Resettable Batch Totalizers: Essential for fuel dispensing or filling containers where you need to zero out after every task.

- Non-Resettable Lifetime Totals: A “permanent” odometer for your system to track total consumption for maintenance and auditing.

- Pulse Output Integration: Even though it’s a mechanical meter, I often include a reed switch or hall effect sensor option for those who want to send data to a remote PLC while keeping the mechanical backup.

The simplicity, reliability and cost-effectiveness of mechanical oil flow meters explain their enduring importance in today’s industrial field.

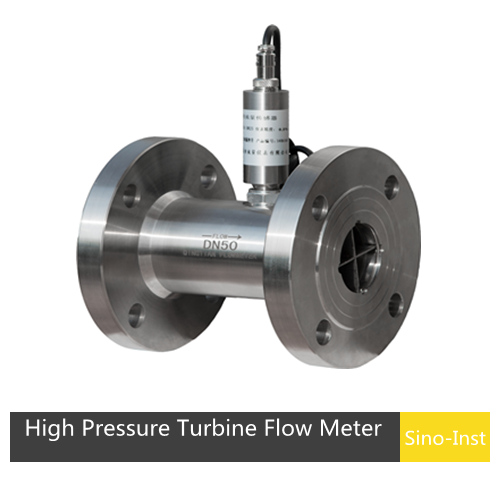

Featured Mechanical Oil Flow Meters

Digital oil flow meter

Of course, digital flow meters are also constantly developing and updating. They generally have the following advantages:

- Local digital display. It can display instantaneous flow and cumulative flow. This can provide more intuitive feedback of flow data.

- Signal output. By connecting the flow signal of the digital oil flow meter, people can remotely monitor the flow situation and even control the oil pipeline.

Featured Digital Oil Flow Meters

Choose a suitable oil flow meter

When choosing an oil flow meter, the following factors need to be considered comprehensively:

- Measurement accuracy requirements: According to the control requirements of the production process and the accuracy requirements of the measurement results, select a flow meter with appropriate accuracy. For example, 0.5%, 0.2%, 0.1%.

- Oil properties: Consider the viscosity, conductivity, temperature, pressure and other properties of the oil.

- Flow range: Select a flow meter with an appropriate range according to the actual flow range. To ensure the accuracy and reliability of the measurement.

- Installation conditions: Consider factors such as the installation position, straight pipe length, and vibration of the flow meter. Choose a flow meter that is easy to install and simple to maintain.

- Cost factors: According to the budget and economic benefits, choose a flow meter with high cost performance.

Different types of oil flow meters have their own advantages and disadvantages, and they need to be selected according to specific circumstances in actual applications.

When choosing, factors such as measurement accuracy, applicable scope, pressure loss, stability, installation requirements and price should be considered comprehensively. To ensure that a suitable oil flow meter is selected to meet the control and optimization needs of the production process.

At the same time, during use, attention should also be paid to the installation, maintenance and calibration of the flow meter. To ensure its long-term stable operation and measurement accuracy.

More Featured Flow Measurement Solutions

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Industrial Oil Flow Meters

- Analog Flow Meters: An Encompassing Guide

- Industrial Hydraulic Flow Meters | Mechanical & Digital

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

- Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Volumetric Flow Meters: Comprehensive Guide and Product List

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

In our experience, the debate between mechanical and digital isn’t about which technology is “newer,” but which one actually survives your work environment. When you’re operating in remote fuel depots or off-grid locations, a mechanical oil flow meter is often the superior choice because it is a true no power flow meter. You don’t have to worry about dead batteries, wiring issues, or signal interference during a critical transfer.

We at Sino-Inst supply various types of oil flow meters. Including oval gear flow meters, turbine flow meters, mass flow meters, etc. For oil flow measurement, we have rich experience in selection.

If you need to purchase Mechanical Oil Flow Meters, or have related technical questions, please feel free to contact us.

-1.jpg)