Slurry and sludge flow measurement is complex and challenging. Accurately measuring slurry flow can improve efficiency and reduce costs in industries such as wastewater treatment, water conservancy projects, river dredging, and oil well cementing.

Slurry flow meters measure the volumetric flow of sludge and slurries in pipelines. Examples include cement slurry, mud, pulp, various acid, alkali, and saline solutions, as well as food slurries. Sino-Inst offers a variety of custom flowmeters for effective flow monitoring.

What is slurry?

Slurry is a fluid composed of water mixed with other impurities, typically soil, particles, or even oil. Depending on the mixture, slurry can be highly viscous and corrosive, making slurry flow measurement challenging.

For example, slurry wastewater from ordinary factories has a relatively low solid content. Slurry generated from industrial wastewater treatment can be corrosive. And mining mud can contain oil.

Challenges of Slurry Flow Measurement

- Complex Composition

Slurries contain varying proportions of impurities, resulting in varying properties. If impurity particles and liquid flow at different velocities, laminar or turbulent flow is more likely to occur. - Corrosive and Abrasive

Slurries produced in chemical plants and wastewater treatment plants may contain corrosive components. Slurries with high solids content, when flowing at high speeds, can also wear out pipes and flow measurement equipment. - High Viscosity

Slurries and slurries can have high viscosity. This low fluidity and high viscosity at low flow rates can easily lead to clogging and stagnation, often affecting flowmeter performance. - Noise and Grounding

The flow of particles in slurries generates noise and vibration. Therefore, grounding techniques are essential to ensure signal integrity during flowmeter operation. - Limited Available Technologies

Impurity particles in slurries render many rotor-type flowmeters, such as gear and turbine flowmeters, unsuitable. Electromagnetic flowmeters, mass flowmeters, and differential pressure flowmeters are preferred.

Featured Sludge & Slurry Flow Meters

Electromagnetic Flow Meter for Slurry Measurement

Electromagnetic flowmeters are generally the preferred choice for measuring slurries and sludge.

First, electromagnetic flowmeters have no moving parts or flow-blocking components. Particles and suspended matter in the slurry will not cause wear or blockage.

Second, electromagnetic flowmeters are highly accurate and sensitive to flow rate fluctuations. As long as the slurry has sufficient conductivity, they can stably measure flow.

Finally, electromagnetic flowmeters can be customized with corrosion-resistant lining and electrode materials. They are suitable for high-viscosity and highly corrosive liquids and can operate stably under harsh conditions.

Technology Guide to Magnetic Flow Meters

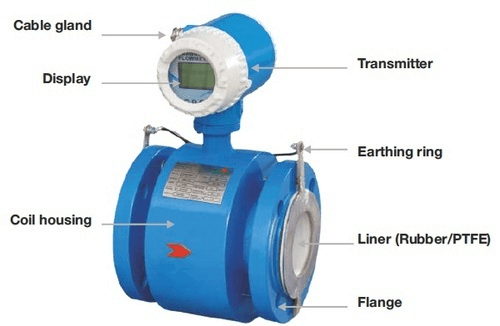

A Magnetic flow meter, also called electromagnetic flow meter, mag flow meter, or magmeters. A magnetic flow meter is a volumetric flow meter that works with principle of magnetic technology. Magnetic flow meters do not have any moving parts. An electromagnetic flowmeter consists of two parts: Electrode (sensor) and Transmitter. Installation types of magmeters could be: Compact, remote, insertion.

Magnetic Flow Meters

Electromagnetic flow meters, also called mag meters or magnetic meters. Magnetic Flow Meters are volumetric flow meters. Mag meter is ideal for wastewater applications, or any dirty liquid which is conductive or water based. Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better.

Ultrasonic Flow Meter for Slurry Measurement

Ultrasonic flowmeters are popular for their non-immersion measurement technology. However, conventional transit-time ultrasonic flowmeters are not suitable for slurries containing impurities. Doppler ultrasonic flowmeters, on the other hand, can tolerate particle impurity levels as low as 15%.

Therefore, Doppler ultrasonic flowmeters are also a good choice when the impurity content is low and opening the pipe is not possible.

Technology Guide to Ultrasonic Flow Meters.

Ultrasonic flow meters are non-intrusive type liquid flow meters. Ultrasonic flowmeter measures the flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse). There are two types of ultrasonic flow meter technologies: Doppler shift and transit-time. Ultrasonic flowmeters measure the fluid flow rate in a pipe. With the sound waves transit time principle to determine the flow rate. Ultrasonic flow meters, with easy installation, could be clamp on, handheld, and portable.

Ultrasonic Flow Meters

Ultrasonic flowmeters measure the fluid flow rate in a pipe. With the sound waves transit time principle to determine the flow rate. Ultrasonic flow meters, with easy installation, could be clamp on, handheld, and portable. Ultrasonic meters are ideal for liquid applications. Like: water, wastewater, Fuel, applications or any dirty liquid in the pipe. And for Natural Gas flow measurement, SI-3404 Ultrasonic Gas Flow Meter is a new type flow meter.

Coriolis Mass Flow Meter for Slurry Measurement

Coriolis mass flowmeters have an extremely wide range of applications, suitable for measuring a wide range of fluids, including liquids, gases, and slurries. They can accurately measure these fluids. Furthermore, they can operate stably under harsh operating conditions such as high temperature, high pressure, and high viscosity.

Coriolis mass flowmeters also offer a unique advantage: they can simultaneously measure mass flow, temperature, and density.

Technology Guide to Coriolis Mass Flow Meters.

Coriolis mass flow meter is also called micro motion flow meter. Coriolis mass flow meter is a mass flow meter based on the Coriolis force. Coriolis mass flow meters and thermal mass flow meters are the most common mass flow meters. Corolis mass flow meters arethe best choice for all process and custody transfer (CT) applications. A Coriolis mass flow meter can measure different values at the same time. Mass, volume flow, density and concentration measurement of liquids and gases. This is the most important difference among Coriolis mass flow meter, DP and oval gear flow meters.

Mass Flow Meters

Mass Flow meters for all industrial flow measurement. Coriolis mass flow meters and Thermal mass flow meters. Coriolis Mass flowmeters are ideal for liquid flow measuring applications. And Thermal Mass flowmeters are for compressed gas applications. Thermal mass flow meters are available in types of in-line, insertion, and remote mount transmitters.

Differential Pressure Flow Meter for Slurry Measurement

Differential pressure flowmeters use the differential pressure principle to measure the flow of liquids, gases, and steam. They offer high media compatibility.

V-cone flowmeters and orifice plate flowmeters are suitable for use with liquid media containing solid particles, such as mud, slurry, sand-laden crude oil, sewage, heavy oil, and residual oil.

Differential Pressure Flow Meter Technology

Differential Pressure Flow Meters also called DP flow meters. Differential pressure flow meters consist of flow sensors and pressure/differential transmitters. DP Flow Meters measure the flow rate based on the differential pressure measured by the flow sensor parts. Flow sensors are the important part of differential pressure flow meters. Like: Orifice plate, Venturi tube, Wedge, V-cone and Averaging Pitot Tubes.

Differential Pressure Flow Meters

Differential pressure flowmeters are classified by structural form: standard orifice plate, standard nozzle, classic Venturi tube, V-cone, wedge orifice plate, Annubar, etc.

Featured Applications

Effective slurry flow monitoring is required in many industries.

| Industry | Slurry Type |

| Paper and pulp industry | Pulp: A mixture of wood fiber and water used in the papermaking process. Recycled pulp: A mixture of shredded paper and water used to make new paper products. |

| Water and wastewater treatment | Sewage sludge: A semi-solid slurry consisting of water and waste solids, treated to extract usable water or safely dispose of the waste. Lime slurry: Used in water treatment plants to adjust pH.” |

| Construction | Concrete and cement slurry: A mixture of cement, sand, and water used in construction. Drilling mud: A slurry of water, clay, and other additives used in drilling operations to lubricate and cool drill bits and to collect cuttings.” |

| Food and beverage industry | Pulp and juice concentrate: A slurry of fruit solids and juice used in beverage and food production. Starch slurry: Used in food processing to make products such as sauces and gravies.” |

| Mining and mineral processing | Ore slurry: A mixture of finely crushed ore and water used in mineral extraction processes. Tailings: The slurry remaining after minerals are extracted from an ore, typically containing sand, clay, and other materials.” |

| Dredging vessels | Mixed liquid of shell, silt, and seawater. |

| Oil well cementing | Includes drilling fluids, cement slurries, and pre-pad fluids. |

Selection of Slurry Flow Meter

What Flowmeter Will Work Best for Your Application?

From electromagnetic flowmeters to variable area flowmeters to Coriolis flowmeters, flowmeter options are diverse. However, they vary significantly in functionality, accuracy, and price.

Electromagnetic flowmeters are the preferred flowmeter for many conductive fluids. However, they require pipe cutting.

Ultrasonic sensors provide accurate and non-intrusive measurement through common pipes, making them an excellent versatile option at a higher price point.

For process fluids with higher viscosities, mass flowmeters offer higher measurement accuracy.

When selecting a flowmeter, the following factors must be considered:

- Flow measurement type: velocity, volume, or mass flow

- Media: Media type (liquid, gas, or slurry) and any special conditions, such as particulate matter and viscosity

- Media conditions: Media pressure and temperature, and whether media conditions remain constant or vary

- Flow range: Required media flow range (required minimum and maximum readings)

- Accuracy: Required reading accuracy

- Environmental considerations: Special installation considerations, such as sanitary installation or installation in an ATEX area.

More Flow Measurement Solutions

Sino-Inst is a Professional Slurry flow meter manufacturer and supplier. We offers over 10 slurry flow meter products. About 60% of these are magnetic flow meters, and others are ultrasonic and mass flow meters. A wide variety of Slurry flow meter options are available to you, such as free samples, paid samples.

Sino-Inst’s flow meters service for industrial applications, like: Cooling water, industrial gas, corrosives and brine, chemical processing, mining, Wastewater, energy, electronics, laboratories, medical, and many other industries.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Flow meter products are most popular in the Domestic Market, Southeast Asia, Europe, and Americas.

-1.jpg)