High temperature pressure transducers are designed for high temperature gas, steam and liquid pressure measurement. With cooling element, our high temperature pressure transducers can withstand high temperatures up to 300℃~500℃~800℃~1200℃. The pressure is up to 14503.8 psig (100MPa). The high temperature differential pressure transmitter can also meet high temperatures of 600℃~800℃.

Our High temperature pressure transducers and differential pressure transmitters are available in mV, 4-20 mA, 0-10 VDC or 0-5 VDC output configurations. There is also HART protocol, and RS485 communication optional.

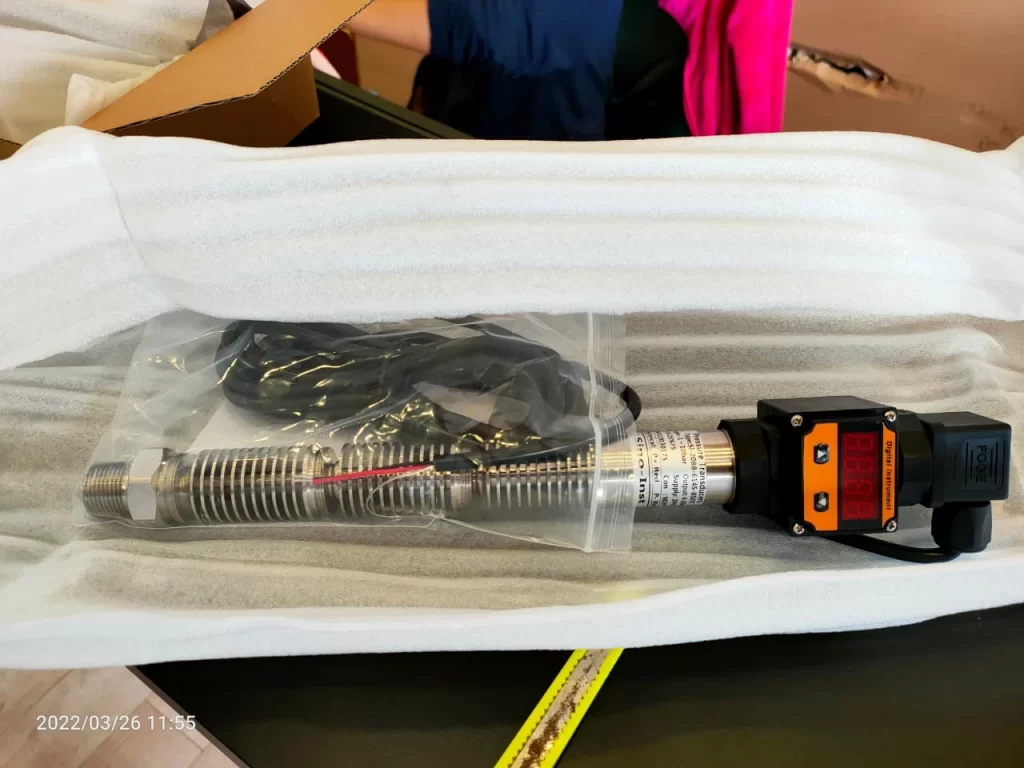

Featured High Temperature Pressure Transducers

Pressure transducers should not come into direct contact with high-temperature media. Prolonged exposure to high-temperature media can easily damage the pressure transmitter. When measuring high-temperature media, a common design approach is to incorporate a mechanical cooling element to dissipate heat and reduce the temperature near the pressure transmitter.

The cooling element can be filled with oil and isolated from the process media by an isolation diaphragm. Alternatively, the cooling element can include a hollow tube. The shape of the hollow tube is designed to increase heat transfer, allowing the process media to pass through to be cooled to a much lower temperature.

Cooling elements typically rely on convection heat transfer, a mechanism that uses fluid motion to transfer heat.

Sino-Inst high-temperature pressure transducers use a high-temperature-resistant pressure sensor as the signal measurement element. The sensor consists of two diaphragms: a titanium alloy pressure-sensing diaphragm and a titanium alloy measuring diaphragm. The pressure of the measured medium is transmitted from the pressure-sensing diaphragm to the measuring diaphragm.

The transmitter structure includes a heat dissipation structure. High-precision signal processing circuitry is located in a stainless steel housing, converting the sensor output signal into a standard output signal. The entire product undergoes rigorous testing and burn-in screening of components, semi-finished products, and finished products, ensuring stable and reliable performance. Suitable for industrial applications, food and pharmaceutical equipment, power generation, machinery manufacturing, automotive and shipbuilding, petrochemicals, metallurgy, and steam and heat exchange.

SI-706 Combined Pressure and Temperature Transmitter

- Range: 0-20, 30-600KPa, 1, 5, 10, 20, 50-100MPa

- Comprehensive accuracy: 0.2%FS, 0.5%FS, 1.0%FS

- Output signal: 4-20mA (two-wire system), 0-5/1-5/0-10VDC (three-wire system)

- Temperature signal output: J, K, E type thermocouple or PT100 platinum resistance, digital temperature signal DS18B20

- Supply voltage: 24VDC (10-30VDC)

- Medium temperature: -20℃~85℃~150℃~800℃

SI-90 High Temperature Dynamic-High Frequency Pressure Sensor

- Measuring range: -100KPa~0-20KPa…1MPa…100MPa (gauge pressure, negative pressure, composite pressure):

- Measuring medium: Gases or liquids compatible with 316 stainless steel

- Static accuracy: ±0.1%FS ±0.25%FS ±0.5%FS

- Natural frequency: 150KHz-700KHz; 500KHz-1MHz; 1MHz-2MHz

- Transmitter bandwidth: 0-1KHz-3 KHz; 0-20 KHz;0-200 Khz

- Signal output: Analog signal: current signal: 4-20mA; voltage signal: 0-5V; 1-5V; 0-10V; 0.5-4.5V

- Digital signal: RS485

- Operating temperature: -40~85℃, Special use up to 200℃

Read more about: Steam Pressure Sensor/transducer for Industrial Steam Measurement

Featured High Temperature Differential Presser Transducers

The high-temperature differential presser transducer consists of a differential pressure transmitter and a welded capillary remote transmission flange. It utilizes dual-isolation pressure transmission technology and consists of an ultra-high-temperature measuring end, a normal-temperature pressure transmitting end, and an intelligent differential pressure transmitter.

The diaphragm on the high-temperature measuring end senses the pressure of the high-temperature medium and transmits it to the isolation diaphragm through a special high-temperature-resistant filling fluid within its cavity. This pressure is then transmitted to the differential pressure transmitter via normal-temperature silicone oil within the capillary, thereby achieving pressure measurement.

The high-temperature differential presser transducer is suitable for directly measuring differential pressure and liquid level in ultra-high-temperature media. Its applicable temperature range is 450°C to 600°C. It is widely used in ultra-high-temperature measurement applications such as solar thermal molten salt power generation, petroleum and petrochemical industries, and metallurgical and power generation.

SI-8051DG Monocrystalline Silicon High Accuracy Differential Pressure Transducer

This high-precision differential pressure transmitter is mostly used in differential pressure flow meters. By configuring the pressure tube for cooling, media up to 800°C can be measured.

- Output signal:4~20mA+Hart protocol

- Measuring range:Any range within -0.1MPa~10MPa

- Compensation temperature:-10~70℃

- Storage temperature:-40~125℃

- Medium temperature:-20~85℃

- Pressure type:Gauge pressure, Differential Pressure

- Comprehensive accuracy:0.075%FS, 0.1%FS optional

More about: High-Temperature Media Pressure Measurement Case: 900-1200°C

How do you Measure Steam Pressure?

Pressure monitoring within steam pipelines is crucial, and because of the high temperatures within these pipelines, our high-temperature pressure transmitters, designed specifically for these applications, are ideal.

Steam has a wide range of applications in many industries. In the chemical industry, steam is often used as a heat source. It typically represents saturated steam at a pressure of 0.1-5 MPa and a temperature of 110-250°C.

In thermal and nuclear power plants, steam is used as the driving force for turbines. Subcritical power generation uses superheated steam at a pressure of 17 MPa and a temperature of 540°C. Supercritical power generation uses superheated steam at a pressure of 30 MPa and a temperature of 600°C. Nuclear power generally uses high-pressure saturated steam.

In the medical field, steam is used for high-temperature sterilization at a pressure of 0.7 MPa and a temperature of 160°C.

Chemical plants typically use heat exchangers for chemical processing, heating storage tanks, and heating reactors, typically at temperatures above 120°C. High-temperature sterilization of food is generally performed at temperatures between 100°C and 150°C. Ultra-high-temperature sterilization involves heating at temperatures between 135°C and 150°C.

Sino-Inst high-temperature pressure transmitters utilize a high-temperature-resistant titanium alloy pressure-sensing diaphragm, which offers excellent elasticity and insulation properties. They are insensitive to temperature fluctuations and maintain excellent operating characteristics even under high-temperature conditions. They are widely used for saturated steam measurement in the chemical, power, medical, and food industries.

More solutions for high and low temperature measurement

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Pressure Transducer Troubleshooting: Expert Insights & Tips

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Gauge Pressure vs Absolute Pressure | Differences and Relationships

- Industrial Water Pressure Sensors | Selection Guide

- How to calibrate a pressure transmitter? How often?

- 10 Point Guide! Selection of Pressure Transmitters

- Industrial Liquid Nitrogen Flow Meters

- Flowmeters for Cryogenic Fluids Flow Measurement

High Temperature Pressure Transducers and differential pressure transmitters are mainly used for pressure measurement of high temperature media. By adding a cooling element, the pressure medium such as the measured high-temperature gas and liquid can be cooled, which can effectively reduce the temperature of the pressure medium and reduce the impact of the pressure pulsation of the pressure medium on the pressure gauge. The pressure transmitter can measure high-pressure media accurately for a long time, and is often used for pressure measurement of high-temperature media such as unsaturated steam.

We at Sino-Inst supply high quality industrial pressure transmitters. Supports customization of installation threads, signal output, temperature, pressure range and other parameters.

If you need to purchase High Temperature Pressure Transducers or have related technical questions, please feel free to contact our engineers!

-1.jpg)