Gauge pressure transmitter can realize high-precision measurement of gauge pressure in industrial process. The product is used to measure the level, density and pressure of liquid, gas or steam. Then the pressure signal is converted into 4mA~20mA DC analog current signal output. It can also be configured with HARTRS485, etc. Gauge Pressure Transmitters are suitable for demanding process industrial fields.

What is a gauge pressure transmitter?

When we purchase a pressure transmitter, we need to choose the pressure type. For example, gauge pressure, absolute pressure, and differential pressure. Correspondingly, we need to use a gauge pressure transmitter, an absolute pressure transmitter, and a differential pressure transmitter.

Therefore, Gauge pressure transmitter is a type of pressure sensor that can effectively measure gauge pressure.

The working principle of a gauge pressure transmitter is to pass atmospheric pressure through the air duct in the transmitter cable. The atmospheric pressure is led to one end of the pressure sensing element and compared with the measured pressure. The difference between the two pressures is the measured pressure.

More about: Gauge Pressure vs Absolute Pressure | Differences and Relationships

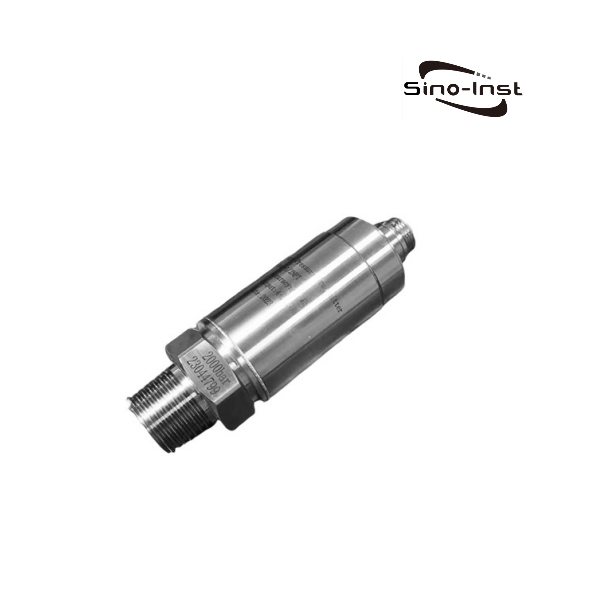

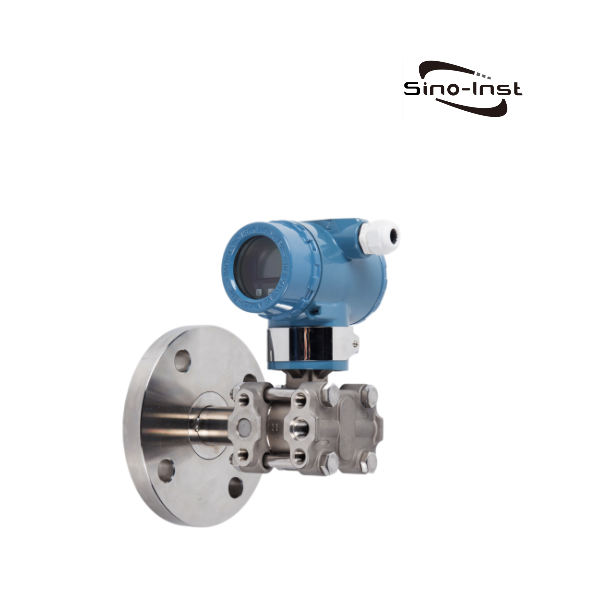

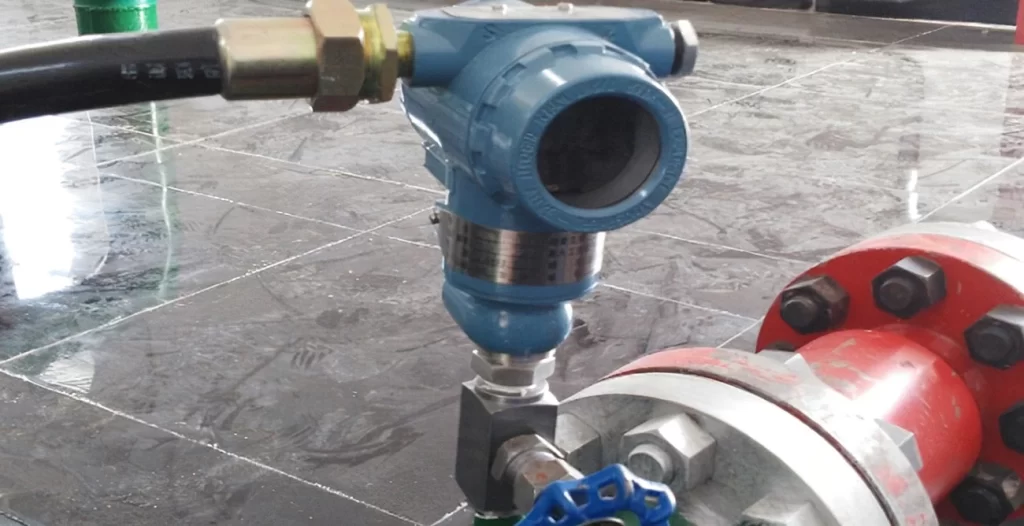

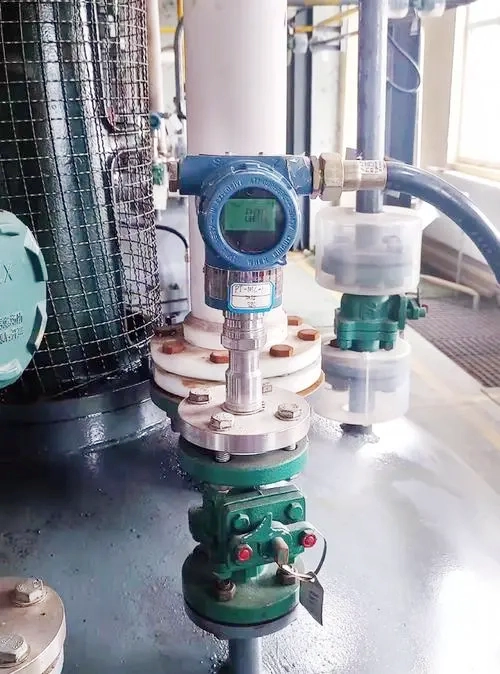

Featured Gauge Pressure Transmitters

Gauge Pressure Transmitter Working Principle

The gauge pressure transmitter measures the process pressure of the medium relative to the atmospheric pressure.

The gauge pressure transmitter, here the gauge pressure means the surface pressure, and its measurement formula is: measured pressure = medium pressure – local atmospheric pressure.

The working principle of the gauge pressure transmitter is to pass the atmospheric pressure through the air guide tube in the transmitter cable, and lead the atmospheric pressure to one end of the pressure sensing element to compare with the measured pressure. The difference between the two pressures is the measured pressure.

The specific sensor principle can be different. For example, single-crystal silicon sensors, metal capacitance sensors, diffused silicon sensors, etc. Technical recommendations can be made based on the actual measurement parameters.

Can gauge pressure transmitters measure vacuum?

No, gauge pressure transmitters have minimum measurement value requirements, and the minimum measurement value can be found in the technical data sheet in the sample. For example, the minimum measurement pressure of the P300/P310/P410/DS III series pressure transmitter is 3kPa absolute pressure, which means that the minimum gauge pressure can be measured is -97kPa, so it cannot measure vacuum.

When selecting a pressure transmitter, what do gauge pressure, absolute pressure, and differential pressure mean?

The so-called pressure refers to the force acting uniformly and vertically on a unit area, that is, pressure. Since there is always atmospheric pressure on the earth, in order to facilitate the expression of pressure values in different occasions, it is divided into three types of expression: gauge pressure, absolute pressure and differential pressure according to different zero standards.

Gauge pressure: The pressure expressed with atmospheric pressure as the zero standard is called gauge pressure. The standard atmospheric pressure value is 101.325kPa. Gauge pressure can be positive or negative. Pressure higher than atmospheric pressure is positive pressure, and pressure lower than atmospheric pressure is negative pressure. Negative pressure is also called vacuum degree. Because process equipment and measuring instruments are generally under atmospheric pressure, gauge pressure is mostly used in engineering to indicate pressure. Unless otherwise specified, it refers to gauge pressure.

Absolute pressure: The pressure expressed with complete vacuum as the zero standard is called absolute pressure, or absolute pressure for short. Absolute pressure has only positive values.

Differential pressure: The difference between the pressures at two points.

More Process Pressure Measurement Solutions

- How to Choose the Right Oil Pressure Transmitter for Your Application

- Industrial Water Pressure Sensors | Selection Guide

- How to calibrate a pressure transmitter? How often?

- Pressure Transducer Troubleshooting: Expert Insights & Tips

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

Sino-Inst produces and supplies various types of gauge pressure transmitters. They can be configured with different ranges, mounting threads, temperature resistance, signal output, and communication protocols. And the accuracy of advanced performance transmitters can reach 0.1%, 0.075%.

Our pressure transmitters are widely exported to the United States, the United Kingdom, Singapore, Canada, etc., and are suitable for water treatment equipment automation, pipeline pressure monitoring, energy management and other industries.

If you need to purchase gauge pressure transmitters, or have parameter customization requirements. Please feel free to contact our sales engineers!

-1.jpg)