Gas flow measurement is an essential technology in many industrial processes. For example, in the production of chemical products, accurate measurement of the flow of gases such as oxygen and nitrogen can ensure that the reactants are added to the reactor in the appropriate proportion to obtain high-quality products.

Introduction: Why Gas Flow Measurement is Important

The measurement of air and other gases in manufacturing plants in the chemical process industries (CPI) is essential in many constructive applications. Including safety, process control, product quality, production efficiency, environmental conformity and costs.

When the measurement of air or other gases is imprecise or inconsistent, some potential outcomes include serious accidents, emergency shutdowns, unplanned maintenance, production slowdowns or cost overruns.

There are 6~8 viable flow measurement technologies for gases available today. But only about half of them are suitable for the heavy-duty metering applications found in the most challenging CPI operations.

Each technology has its own strengths and weaknesses, depending on exactly what material needs to be measured, the required accuracy, where it needs to be measured and so on.

The truism “knowledge is power” definitely applies when it comes to choosing a flow meter for gas measurement tasks. The same flow-sensing technology that is chosen for one application in a plant is quite possibly the wrong choice in a different exercise — even one that is in close proximity within a facility.

The cost of deciding the wrong flow meter — in terms of extra maintenance, repairs and spares in large CPI plants is huge.

Parameters to Consider When Choosing a Gas Flow Meter

Selecting the suitable gas flow meter depends on several components, including:

- Type of Gas

- Flow information

- Flow Rate

- Process Conditions

- Pressure

- Temperature

- Accuracy Requirements

- Installation and Maintenance

Types of Gas Flow Meters in detail

Gas flow meters come in various designs and technologies, each suited for specific applications. The main types of gas flow meters include:

- Differential Pressure Flow Meters

- Thermal Mass Flow Meters

- Ultrasonic Flow Meters

- Turbine Flow Meters

- Vortex Flow Meters

Differential Pressure Flow Meters

Differential pressure flow meters measure the flow of gas by calculating the pressure drop over an obstruction placed in the flow path. Common types include orifice plates, flow nozzles etc.

Thermal Mass Flow Meters

Thermal mass flow meters measure the flow of gas based on the law of heat transfer. These meters are perfect for measuring low flow rates and are often used in applications such as HVAC systems, biogas monitoring, and industrial gas flow measurement.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure the velocity of gas flow. There are two main kinds: transit-time and Doppler. Ultrasonic flow meters are non-intrusive and are ideal for applications where the gas flow needs to be measured without disrupting the process.

Turbine Flow Meters

Turbine flow meters measure the gas flow by using a rotor placed in the flow stream. These meters are suitable for clean, non-corrosive gases and are commonly used in natural gas pipelines and HVAC systems.

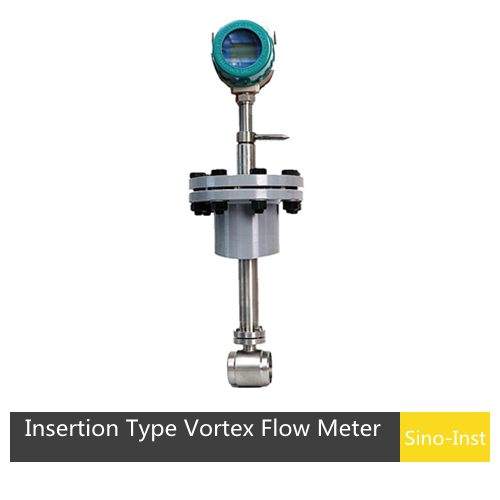

Vortex Flow Meters

Vortex flow meters measure the flow rate of gas by detecting the vortices shed by a bluff body placed in the flow stream. Vortex meters are versatile and can handle a wide range of gases, making them appropriate for applications in the chemical, petrochemical, and energy industries.

Inline vs. Insertion Gas Flow Meter

An in-line gas flow meter has a flow line installed in a process line and has a built-in flow conditioner that enhances the profile of the process gas. Here we use a thermal gas flow meter Take for example, the comparison of inline and insertion style flow meters.

| Attributes | Inline gas flow meter | Insertion gas flow meter |

| Configuration | The inline or in-line gas flow meter includes a flow body installed more permanently in a process line. | In this configuration, the meter’s probe inserts into the process pipe. |

| Advantages | One of the in-line meter advantages is that it does not need as much of a straight run as the insertion-style meter permitting the end-user to cut down the length of the upstream straight run to three pipe diameters in most cases. | One of the important advantages of the insertion-style meter is the ease of installation; additionally, the style has an captivating price. |

| Usages | This meter configuration has a built-in flow conditioner that optimizes the flow profile of the process gas. | The insertion-style thermal gas flow meter is appropriate for temporary or semi-permanent gas flow measurement. |

Mass Gas Flow Meters

Mass gas flow meters are specifically designed to measure the mass flow rate of gases, rather than just the volumetric flow. This is particularly important in applications where the density of the gas may vary due to changes in temperature and pressure. There are two main types of mass gas flow meters: thermal and Coriolis.

Thermal Mass Flow Meters

As mentioned earlier, thermal mass flow meters measure the gas flow based on heat transfer principles. These meters are highly sensitive to low flow rates and provide accurate measurements even in fluctuating process conditions.

Thermal mass flow meters are commonly used in applications such as:

- Biogas Monitoring: To measure the flow of biogas produced in anaerobic digestion processes.

- HVAC Systems: For monitoring airflow in heating, ventilation, and air conditioning systems.

- Industrial Gas Flow Measurement: In various industries to measure gases such as nitrogen, oxygen, and carbon dioxide.

Coriolis Mass Flow Meters

Coriolis mass flow meters offer high accuracy and can measure both mass flow and gas density. They are ideal for applications requiring precise measurement and control, including:

- Chemical Processing: To measure the flow of reactants and products in chemical reactions.

- Natural Gas Measurement: For custody transfer and distribution of natural gas.

- Food and Beverage Industry: To monitor the flow of gases used in carbonation and packaging processes.

Gas Flow Measurement Solutions

Sino-Inst can provide customized gas flow measurement solutions for different gases and different application conditions.

FAQ

More Flow Measurement Solutions

- Irrigation Flow Meters-Indispensable for Modern Agriculture and Irrigation

- Ultrasonic Flow Meters: Doppler Effect vs Transit Time

- Doppler Effect Ultrasonic Flow Meters | Sino-Inst

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Electronic Flow Meters-Digital Display

Summery: Making an informed decision

Gas flow measurement is a key element of many industrial processes, ensuring operational skillfulness, safety, and cost management.

Sino-Inst is a Professional flow meter manufacturer and supplier from China. Sino-Inst offers over 50 flow meter products. Including differential pressure, thermal mass, Coriolis, ultrasonic, turbine, vortex, and rotameters. It’s primary to choose the right type for your circumstantial application.

One of the outstanding gas flow meter from Sino-Inst is SI-3201 GAS Turbine Flow Meter; it is the flange type turbine flow meter. It is a perfect choice for natural gas flow rate measurement.

If you need to purchase gas flow meters, or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)