Explosion proof pressure transducers are pressure measurement devices that are third-party certified for safe operation in hazardous environments. Mainly used in petroleum, chemical industry, coatings, pharmaceuticals and other flammable and explosive places.

Explosion-proof technology is employed, meaning the transmitter’s flameproof housing is designed to withstand the pressure generated by an internal explosion while preventing the flame and energy generated by the explosion from propagating outward, thereby preventing the explosion.

Explosion Proof Pressure Transducers converts the absolute pressure or gauge pressure of the measured medium into standard electrical signals such as 4~20mA, 0~5VDC, 0~10VDC and 1~5VDC.

Sino-Inst manufactures and supplies a wide range of Explosion Proof Pressure Transducers and differential pressure transmitters. Intrinsically safe or flameproof explosion-proof grades can be customized. Measuring medium, pressure range, temperature, installation size and signal output, etc., can all be customized according to your needs!

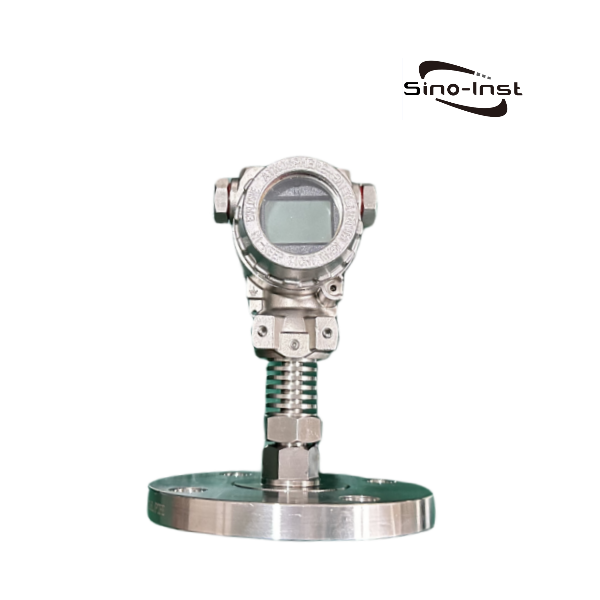

Featured Explosion Proof Pressure Transducers

Explosion Proof Differential Pressure Transmitters

Explosion-proof grade of pressure transmitter

Explosion-proof level refers to the ability of electrical equipment to operate normally or stop operating in an explosive gas mixture environment without causing an explosion or fire. Under the requirements of explosion-proof level, the pressure transmitter needs to choose an explosion-proof model.

Commonly used explosion-proof levels are Exd, Exia, and Exib levels.

Among them, the Exd grade has strong explosion-proof capabilities and is suitable for explosive environments such as coal mines.

The Exia grade is suitable for general industrial locations.

The Exib grade is suitable for places with flammable and explosive gases such as dimethyl ether and ethanol.

Such as ExiaⅡCT4, ExiaⅡCT5 and ExiaⅡCT6, etc.

Among them, ExiaⅡCT4 has a lower explosion-proof level and is suitable for environments with less flammable gases.

Exia II CT6 has a higher explosion-proof level and is suitable for environments with severe flammable gases.

Different Explosion Proof Pressure Transducers explosion-proof levels can be selected according to different use environments and needs.

Difference between explosion-proof and flameproof pressure transmitters

Explosion-proof type is generally used in flammable and explosive environments, such as coal mines, gas stations and other fields. It is divided into two types: explosion-proof type and intrinsically safe explosion-proof type. Their functions are similar, but they are essentially different types of explosion-proof type.

Explosion-proof flameproof technology uses isolation measures to isolate the circuit from the surrounding environment in terms of structure. The heat generated by the circuit during normal operation and the sparks and high temperatures formed during the fault state are all limited to the sealed shell. To prevent ignition of surrounding flammable and explosive gases. In layman’s terms, it is to add a layer of explosion-proof box outside the product to isolate gases or sparks that may cause explosions in the surrounding environment from the air.

Intrinsically safe technology is generally used in instruments. By limiting the energy in the electrical circuit and cooperating with the structural design of the electrical equipment, the sparks or thermal effects that may be generated under normal and accident conditions are respectively less than the minimum ignition energy of explosive hazardous gases. and autoignition temperature.

ATEX pressure transmitter

ATEX certification refers to the “Equipment and Protection Systems for Potentially Explosive Atmospheres” (94/9/EC) directive adopted by the European Commission on March 23, 1994.

This directive covers both mine and non-mine equipment. Unlike previous directives, it includes mechanical equipment as well as electrical equipment. Extend the potentially explosive environment to dust, flammable gases, flammable vapors and mist in the air.

This directive is the “new method” directive commonly known as ATEX 100A, which is the current ATEX explosion protection directive. It specifies the technical requirements to be applied to equipment intended for use in potentially explosive atmospheres – the basic health and safety requirements and the conformity assessment procedures that must be adopted before the equipment can be placed on the European market within its scope of use.

Pressure transmitters certified for use in hazardous areas, i.e. ATEX certified Explosion Proof Pressure Transducers, must be used with an intrinsically safe isolation barrier in order to achieve intrinsic safety.

More Pressure Measurement Solutions

- Voltage Output Pressure Transducers | 0-5/10V DC, 1~5VDC, 0.5~2.5VDC

- Industrial Hydrogen Pressure Transmitters/Transducers

- Pressure Transducer Output Signal Guide

- Industrial Smart Pressure Transmitters 4-20mA, HART, RS485 Modbus

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

Many industrial sectors such as petroleum, chemicals, and coal often leak or spill various flammable and explosive gases, liquids, and various dusts and fibers during production, processing, transportation, and storage. Such substances may become explosive mixtures when mixed with air. When the concentration of the mixture reaches the explosive concentration range, serious accidents such as explosions and fires will occur once a fire source appears.

Instruments and equipment used in such hazardous environments must be products with explosion-proof performance certified by professional organizations.

Sino-Inst explosion-proof pressure sensors feature intrinsically safe explosion protection (Exia IIC T6 Ga) and explosion-proof (Exd IIC T6 Gb) certifications. They operate reliably in environments with explosive gas mixtures, eliminating your concerns.

-1.jpg)