What is Liquid Level Controller?

Liquid level controller refers to the control of high and low liquid levels through mechanical or electronic methods. Can control solenoid valves, water pumps, etc. Used to monitor fluid levels and ensure fluids remain at set levels.

This enables semi-automatic or full automation of tank liquid level monitoring and control. There are many methods, which vary according to the products selected.

Liquid level controller, also known as liquid level switch, is mainly a switch used to control liquid level. Sino-Inst supplies contact and non-contact level controllers.

Featured Liquid Level Controllers and Switches

Liquid level automation control principle

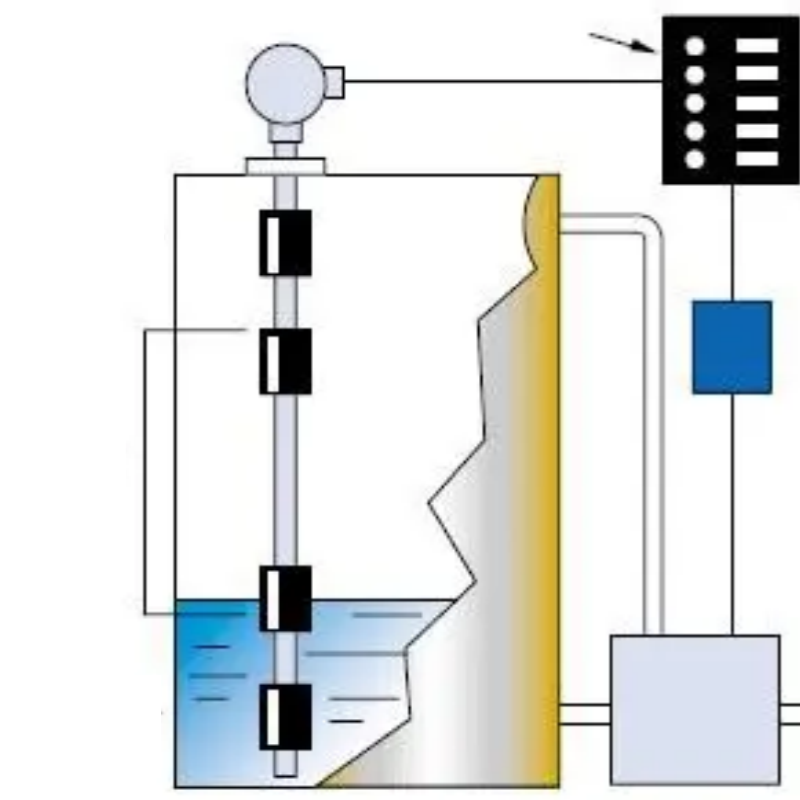

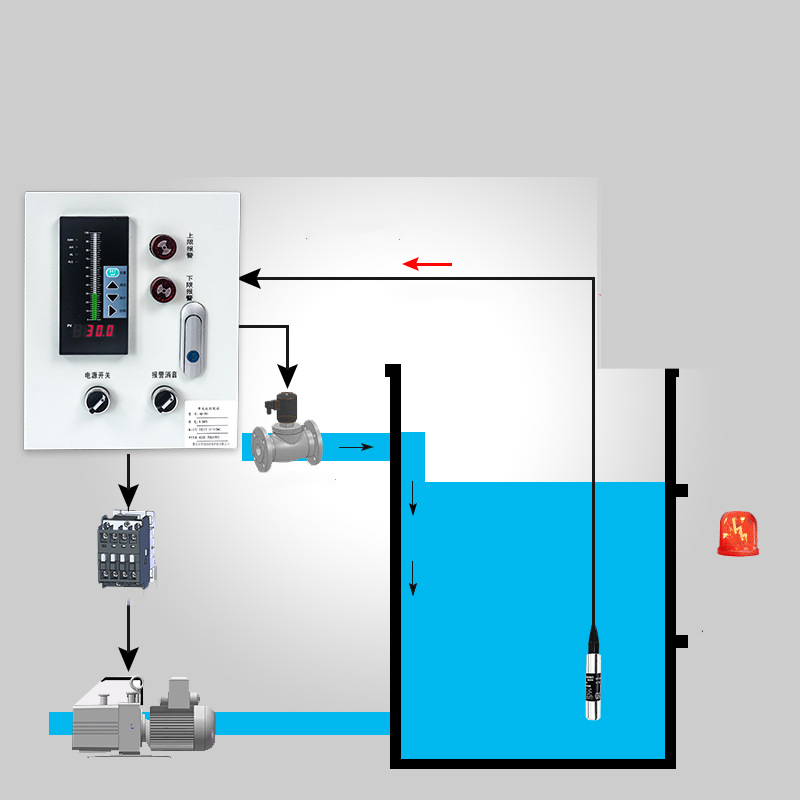

The liquid level control system consists of a liquid level sensor, a liquid level regulator (liquid level controller), and a regulating valve (a pneumatic regulating valve or an electric regulating valve). It can complete the fully automatic control of liquid level value in modern industrial process control system. It has fast response, high control accuracy, extremely convenient setting and reliable performance.

There are two types of functions that implement control (switching). The first is to use the liquid level controller directly. The liquid level sensor detects the liquid level and outputs a relay signal when the liquid level reaches the set value. Control subsequent solenoid valves, etc. Also called a liquid level switch.

The second is to use the liquid level sensor + liquid level controller in combination. The liquid level sensor compares and calculates the detected liquid level value, and promptly outputs an analog signal (4-20mA or 1-5V) to the liquid level controller. Alarm output from the liquid level controller: relay control output—AC220V/2A, DC24V/2A (resistive load).

Of course, this liquid level controller is a dedicated secondary instrument and can be configured with many functions. Such as storage, alarm, RS485 communication, printing, etc.

Types of liquid level controllers

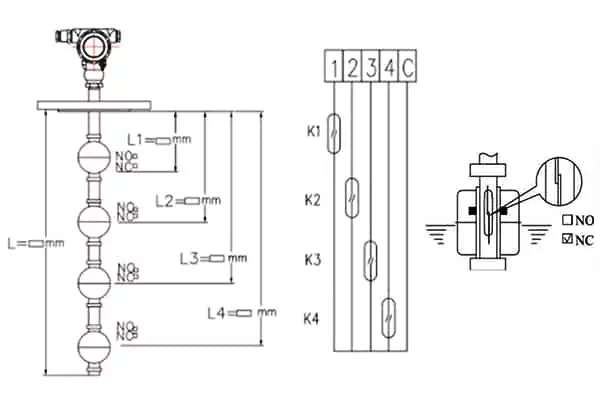

Float level controller

The magnetic float moves up and down along the measuring tube along with the measured liquid level. Its magnet causes the reed at the corresponding position in the conduit to switch instantaneously. Output the corresponding position contact signal. Cooperating with the corresponding control circuit, the automatic control of the liquid injection or pumping pump can be completed to control the liquid level within the specified range.

The position contact signal cooperates with the alarm circuit and can be used for alarm and control of dangerous liquid levels (over the upper limit and over the lower limit).

Ultrasonic liquid level controller

Ultrasonic liquid level controller is a type of non-contact liquid level controller. You can choose top-mounted ultrasonic sensors or external-mounted ones.

Our conventional ultrasonic level meters and explosion-proof ultrasonic level meters can all be configured with relay outputs. At the same time, the liquid level signal of analog signal can also be output.

The external ultrasonic liquid level controller (also called external liquid level switch) is a new type of liquid level monitoring and alarm device. The high-frequency ultrasonic pulse generated by its sensor (probe) can pass through the container wall, and this pulse will propagate in the container wall and the liquid. It will also be reflected back. By detecting and calculating this reflection characteristic, it can be determined whether there is liquid in the container at the monitoring point.

At the same time, the liquid level controller can output signals to subsequent electrical appliances or other equipment to achieve monitoring or control of the liquid level.

The liquid level controller is mainly used to monitor the liquid level of the storage tank, achieve upper and lower limit alarms or monitor whether there is medium in the pipeline (dry protection).

It can be used for liquid level process control in medicine, petroleum, chemical industry, electric power, food and other industries. This product is an ideal choice for monitoring toxic and highly corrosive dangerous liquids.

Electronic liquid level switch control

The electrode type liquid level controller is used for liquid level measurement and control of conductive liquids such as water. Using the conductivity of the liquid, the controller will act to cut off the power when the liquid level reaches a certain height. When the liquid level is lower than a certain position, the power is turned on to make the water pump work to achieve automatic control.

Automatic control consists of sensors and control actuators. The sensor of the liquid level controller is generally a wire. Utilizing the conductivity of water, water has poor conductivity and cannot directly drive the relay. Therefore, an electronic circuit is required to amplify the current to drive the relay to work. It is now widely used for liquid level measurement and control in fire water tanks, pools, wells, water towers, etc.

More Level Measurement Solutions

- Difference Between Radar and Ultrasonic Level Transmitter

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

- Featured 5 Guided Wave Radar Level Transmitter Types

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Difference Between Radar and Guided Wave Radar Level Transmitter

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

Liquid level controllers are widely used in chemical, pharmaceutical, food, energy and other industries and play an important role in automated production lines.

By grasping liquid level information in a timely and accurate manner, the liquid level controller can ensure that the liquid level in the liquid container is maintained within a safe and reasonable range to avoid accidents.

The liquid level controller can also realize many functions such as liquid level alarm, liquid level protection, automatic liquid supply, etc. Improve production efficiency and output, and reduce production costs.

Sino-Inst mainly supplies ultrasonic non-contact liquid level controllers, float level controllers, etc. If you need to install a liquid level controller or have related technical questions, please contact our engineers!

-1.jpg)