Electromagnetic flow meters, also called mag flow meters or magnetic flow meters. Electromagnetic flow measurement technology is mature and stable, and is the first choice for conductive liquid flow measurement.

Sino-Inst has extensive measurement experience and offers customized measurement solutions. Our electromagnetic flow meters can be customized with liner and electrode materials, as well as small diameters (DN2), high pressure, and large diameters, among other specialized specifications. They are ideal for water, wastewater, seawater, acids, alkalis, or any other conductive, water-based, or contaminated liquid.

Featured Magnetic Flow Meters

Need help ? Contact us now.

We will offer you the suitable Flow Measurement Solutions !

Electromagnetic Flowmeter Technical Guide

Introduction to Magnetic Flow Meters Technology. How They Work & What Is It? Their applicaitons and use.

What are Electromagnetic Flow Meters?

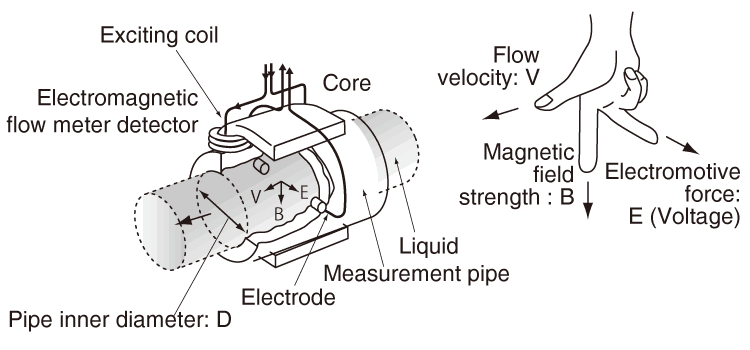

An electromagnetic flowmeter is a flow measurement instrument based on Faraday’s law of electromagnetic induction. It measures the flow rate of a conductive fluid based on the electromotive force (EMF) induced by the fluid passing through an applied magnetic field.

Benefits of Electromagnetic Flow Meters

- The sensor’s measuring tube contains no throttling or obstructing components, resulting in no additional pressure loss.

- It eliminates clogging issues and is suitable for measuring two-phase flows containing suspended matter, solid particles, and fibers (such as slurries with high viscosity, such as mud, sewage, ore slurry, paper pulp, etc.).

- The electromagnetic flowmeter uses four electrodes with a built-in ground electrode, eliminating the need for additional electrical connection rings for use in non-conductive pipes.

- The electromagnetic flowmeter also features a 4-20mA current signal output, a pulse output, and instantaneous flow limit alarm outputs. RS485 communication and HART protocol are also optional.

- Instantaneous flow rate, percentage, flow velocity, forward and reverse cumulative flow, and total accumulated flow are displayed on-site.

How Does a Magnetic Flow Meter Work?

Magnetic flow meters use the principle of Faraday’s Law of Electromagnetic Induction to measure the flow rate of liquid in a pipe. In the magnetic flowmeter pipe parts, a magnetic field is generated, and channeled into the liquid flowing through the pipe. Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. A conductor moving through a magnetic field produces an electric signal within the conductor. And the singal is proportional to the velocity of the water moving through the field. As fluid flows through the magnetic field, conductive particles in the fluid create changes. This variation is used to measure and calculate the velocity of water flow through the pipe. When the fluid moves faster, more voltage is generated. The electronic transmitter processes the voltage signal to determine liquid flow.

What is the principle of magnetic flow meter? – Faraday’s Formula

Faraday’s Formula

E is proportional to V x B x D where:

E = The voltage generated in a conductor

V = The velocity of the conductor

B = The magnetic field strength

D = The length of the conductor

Advantages and Disadvantages of Magnetic flow meters

Advantages of using Electromagnetic Flow Meters

- HIGH PRECISION AND STABILITY

- SELF CHECKING

- BIDIRECTIONAL MEASUREMENT

- NO PRESSURE LOSS

- NO MOVING PARTS

- CAN BE SANITARY USES

- LARGE LINE SIZES AVAILABLE

- DIRTY LIQUIDS AND EVEN SLURRIES OK

Disadvantages of using Magnetic Flow Meters

- ELECTRODES CAN BECOME COATED

- CAN NOT BE USED TO MEASURE LIQUID MEDIA WITH LOW OR NO CONDUCTIVITY

- WILL BE AFFECTED BY STRONG MAGNETIC FIELDS AROUND

- SITLL CAN’T MEASURE HIGH TEMPERATURE AND HIGH PRESSURE FLUID

How to Use Magnetic Flowmeters

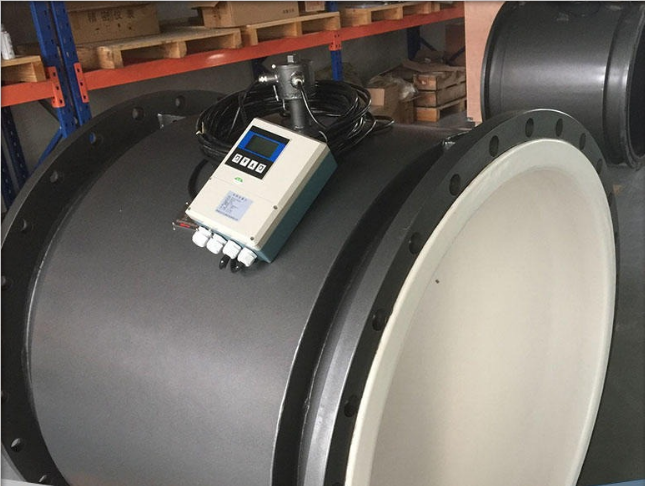

The electromagnetic flowmeter consists of two parts: a sensor and a converter. It is an inductive meter for measuring the volumetric flow of conductive media.

Magnetic flow meters work based on Faraday’s law of electromagnetic induction. Magnetic flow meters measure the volumetric flow of conductive liquid with conductivity greater than 5μS/cm.

Measuring the volume flow of general conductive liquids, it can also be used to measure the volumetric flow rate of strong corrosive liquids. Such as strong acid and alkali, and uniform liquid-solid two-phase suspension liquids such as mud, slurry and pulp.

Magnetic flow meters can be installed in relatively short meter runs. Magnetic flow meters typically require: 5-10 diameters of upstream straight run and 5-2 diameters of downstream straight run.

What Is a Mag Meter Used For?

- Dirty liquids

- Highly corrosive liquids

- Slurry

- Liquid is feed using gravity

Magnetic flowmeters are often used where the liquid is fed using gravity. Be sure that the orientation of the flowmeter is such that the flowmeter is completely filled with liquid. Failure to ensure the flowmeter is completely filled with liquid can affect the flow measurement.

- Vacuum service

Industries that Use Magnetic Flow meters

- Pulp and paper;

- Metals and mining;

- Water and wastewater;

- Food and beverage;

- Chemical;

- Petrochemical;

- Oil and gas.

Application Cautions for Magnetic Flowmeters

Why Does a Magnetic Flow Meter Need Grounding?

Magnetic Flow Meters Selection

The key questions which need to be answered before selecting a magnetic flow meter are:

- Is the fluid conductive or water based?

- Is the fluid or slurry abrasive?

- Do you require an integral display or remote display?

- Do you require an analog output?

- What is the minimum and maximum flow rate for the flow meter?

- What is the minimum and maximum process pressure?

- What is the minimum and maximum process temperature?

- Is the fluid chemically compatible with the flow meter wetted parts?

- What is the size of the pipe?

- Is the pipe always full?

Insertion Magnetic Flow Meters

Insertion Magnetic Flow Meter, also called Insertion type Electromagnetic flow meter. Insertion style flow meter, measures the flow velocity of conductive liquids in large diameter pipes.

Installation Considerations of Magnetic Flow Meters

- Where there is no vibration or strong electromagnetic field (such as large motor and inverter);

- As far as possible vertical installation. Horizontal installation needs to be installed in a low place. Can not install the pipe apex. Ensure full pipe. Prevent air bubbles;

- Straight pipe requirements, it is best to ensure 5 times the diameter of the first 10;

- When welding, please pay attention not to connect the instrument to prevent damage to the flowmeter;

- The shell should be grounded as far as possible. The shielded wire should be grounded at one end, and the point can not be shared with the strong electricity;

- If it is convenient for maintenance, the installation location needs to be selected to meet the maintenance requirements. At the same time, the side pipe can be installed, and the fluid moves along the side pipe when the fault occurs;

- To avoid direct sunlight, high temperature, will degauss;

- Other requirements should be considered, the signal wiring should not be with the strong electric line.

FAQ

How accurate is the Magflow meter

Magflow meter is also called an electromagnetic flow meter, and its measurement accuracy is relatively high. The general accuracy is 0.5%. The insertion measurement accuracy is 1.0%, 1.5%, 2.0%, etc.

What is the difference between mass flow meter and MAG flow meter?

Electromagnetic flowmeters and mass flowmeters are common industrial flowmeters that play an important role in measuring the quality and flow of fluids.

The measurement principles of electromagnetic flowmeters and mass flowmeters are different. Electromagnetic flowmeters measure the flow of liquids by measuring the electromotive force induced by a conductor in a magnetic field. Mass flowmeters determine the flow rate based on the pressure drop when the fluid passes through the pipeline and parameters such as fluid density.

Of course, for the detailed differences between the two, please check: What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

What is the range of a magnetic flow meter?

Our Sino-Inst electromagnetic flowmeter covers the pipe diameter range of DN2~DN3000. Different products can be configured according to different measurement parameters.

Why are electromagnetic flowmeters the preferred choice for measuring water flow?

Electromagnetic flowmeters offer significant advantages in measuring reclaimed water.

First, they offer high measurement accuracy and stability, meeting the precise flow rate, velocity, and direction requirements of reclaimed water.

Second, they are highly adaptable and can be used to measure reclaimed water with varying water qualities and flow rates. As long as the medium conductivity is ≥5 μS/cm (wastewater typically ranges from 100 to 5000 μS/cm), they provide stable measurements without the need for additional calibration.

Furthermore, electromagnetic flowmeters offer advantages such as simple structure and easy maintenance, reducing operational costs and maintenance complexity.

More Flow Measurement Solutions

- Slurry & Sludge Flow Measurement

- High-Pressure Flow Meters

- Cooling Water Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Application of Electromagnetic Flowmeter in Paper Mill Slurry Wastewater Treatment System

- Brewery Flow Meters for Beer and Wine | Electromagnetic and More

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Target Flow Meter Advantages And Disadvantages and Featured Applications

- Magnetic Flow Meter Troubleshooting| Manufacturer’s Guide

Electromagnetic flowmeter, also known as magmeter flow meter, is suitable for various flow rates of liquids and slurries through pipes. It is commonly used in water and wastewater treatment, chemical injection and pharmaceutical manufacturing.

Sino-Inst is a leading supplier of electromagnetic flowmeters, designed to provide reliable and efficient performance. We have many years of experience in flow measurement. If you need to purchase electromagnetic flowmeters or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)