The pulp and paper industry is a major water consumer and one of the leading wastewater generators. Paper industry wastewater can be divided into two types: sulfate pulp wastewater and sulfite pulp wastewater. Wastewater discharged from the pulping process is the most polluting. It contains large amounts of organic matter and suspended solids, as well as numerous chemicals and impurities, and is a major source of water pollution.

Sino-Inst provides supporting instrumentation for the pulp and paper industry, including flow meters, level transmitters, and pressure transmitters.

Features of the Paper Mill Slurry Wastewater Treatment System

Papermaking wastewater is highly hazardous. Blackwater is the most hazardous, accounting for over 90% of the paper industry’s total pollution emissions. Due to its high alkalinity, dark color, strong odor, and high foam content, blackwater depletes dissolved oxygen, severely polluting water sources and posing a threat to the environment and human health.

Among the midstream wastewaters that pose the greatest environmental risk is chlorine-containing wastewater generated during the bleaching process, such as chlorine bleaching effluent and hypochlorite bleaching effluent. Furthermore, bleaching wastewater contains highly toxic carcinogens such as dioxins, posing a serious threat to the ecological environment and human health.

Paper Mill Slurry Wastewater Composition

Pulping and papermaking wastewater is primarily divided into three types: black liquor, midstream wastewater, and white water.

Black liquor: Plant fibers are cooked with an alkaline solution containing sodium hydroxide (NaOH) or sodium hydroxide combined with sodium sulfate to dissolve lignin. The discharged cooking liquid is called “black liquor.” Alkali cooking produces black liquor, while acid cooking produces red liquor. Alkali cooking is the predominant method. Black liquor contains lignin, pentosan, and total alkali, making it a highly concentrated, difficult-to-degrade wastewater.

Intermediate wastewater: This wastewater is generated during the washing, screening, and bleaching processes of pulp produced by alkali cooking. The COD load per ton of pulp is approximately 310 kg. The BOD/COD ratio ranges from 0.20 to 0.35, indicating poor biodegradability. Pollutants primarily consist of soluble COD, such as lignin, cellulose, and organic acids. The most serious pollution is chlorine-containing wastewater from bleaching.

White water: This is a large volume of water, primarily containing fine fibers, fillers, coatings, and dissolved wood components. It is primarily composed of insoluble COD, has poor biodegradability, and the added preservatives are toxic.

Treatment technologies

Black liquor and intermediate wastewater include alkali recovery, acid precipitation, LB-1 alkali precipitation, membrane separation, flocculation and sedimentation, biofilm treatment, anaerobic biological treatment, mesh microfiltration, flotation, and advanced oxidation.

White water: filtration, flotation, sedimentation, and screening.

Paper Mill Flow Measurements

For paper mills, flow measurement and control are important.

To measure the pulp flow into the paper machine, the electromagnetic flowmeter can cooperate with the concentration meter as the feedforward of quantitative control of paper;

The pulp is measured in the pulp blending system, and the electromagnetic flowmeter can realize the continuous or intermittent control of the pulp blending ratio.

At present, most papermaking enterprises have gradually replaced traditional differential pressure flowmeters with electromagnetic flowmeters. Electromagnetic flowmeters dominate liquid metering in the paper industry.

This is because the measurement of the electromagnetic flowmeter is not affected by the fluid’s density, temperature, pressure, viscosity, Reynolds number, and conductivity changes within a certain range. It has a large measurement range and can cover two velocity distribution states of turbulent flow and laminar flow. This is unmatched by differential pressure flowmeters, turbine flowmeters, vortex flowmeters and other flowmeters.

For fiber suspension, the electromagnetic flowmeter can effectively suppress noise fluctuations and improve the accuracy of flow measurement.

Due to the simple structure of the electromagnetic flowmeter, there are no moving parts, disturbing parts and throttling parts that hinder the flow of the measured medium. There will be no problems such as pipe blockage and wear. When the measured medium flows in the sensor measuring tube, there is almost no pressure loss and only consumes 10~20W of electric power. For factories, this can significantly save energy consumption and strictly control the discharge of environmental pollutants.

Process Flow

The paper mill’s terminal wastewater treatment process is generally as follows:

In the treatment system, midstream wastewater flows through a mechanical screen, a collection tank, an inclined screen (for slurry recovery), a primary sedimentation tank, an equalization tank, a selective site, an aeration tank, a secondary sedimentation tank, a collection tank, a coagulation reactor, a tertiary sedimentation tank, a Fenton reactor, a quaternary sedimentation tank, an iron removal aeration tank, an activated sand filter, a clear water tank, and clear water recovery.

In the anaerobic treatment system and sludge treatment system, midstream wastewater flows through a mechanical screen, a collection tank, an inclined screen (for wastewater removal), a primary sedimentation tank, a cooling tower, a water sump, a flotation system, a pre-acidification tank, a circulating water tank, a reactor, and biogas recovery. Sewage then flows through a sludge dewaterer, semi-drying of the sludge, and sludge cake removal.

The midstream wastewater enters the mechanical fine screen to remove large suspended solids. The main purpose of the wastewater treatment system in the collection tank is to remove fine fibers and recover waste paper pulp. In the anaerobic system, it treats the anaerobic system, converting organic matter into biogas that enters the pressure regulator.

Terminal wastewater enters the treatment system directly, where advanced treatment primarily involves degrading organic matter through coagulation, activated sand reaction, and Fenton reaction. Sludge from the wastewater treatment system is primarily mechanically dewatered in a sludge dewaterer for safe disposal.

Featured Electromagnetic Flowmeters for Paper Mill Slurry Wastewater

Learn more about: Magnetic Flowmeter Technology

Paper Mill Slurry Wastewater Treatment System Level Measurement

Chemical storage tanks for pulp and paper production are often closed or semi-closed structures, with typical operating temperatures ranging from +10°C to +95°C and pressures close to atmospheric pressure. Although the pressures are low, the storage media are often corrosive and may generate gases or vapors during storage, leading to signal attenuation or probe corrosion.

For example, liquids such as sodium hydroxide, hydrogen peroxide, and sulfuric acid release gases during storage. Contact probes are susceptible to corrosion and scaling, resulting in unstable measurements. Therefore, non-contact radar and ultrasonic level sensors are ideal choices.

Featured Level Meters for Paper Mill Slurry Wastewater

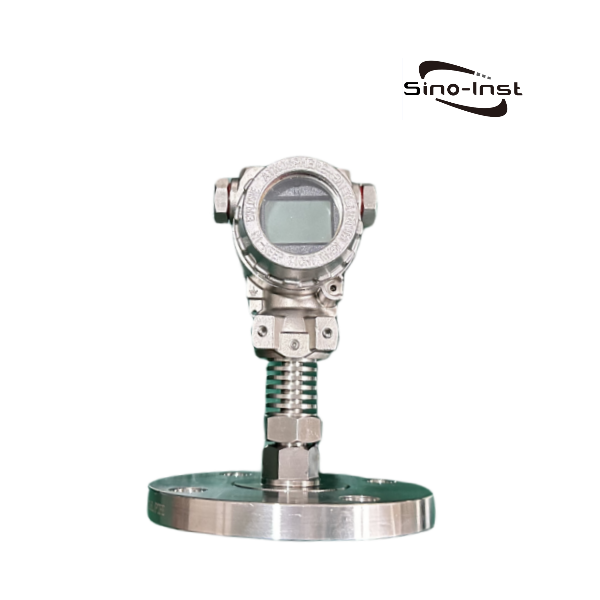

Paper Mill Slurry Wastewater Treatment System Pressure Monitoring

The papermaking process generates large quantities of pulp and chemicals, requiring numerous towers, tanks, troughs, and other containers for storage and transportation. Installing intelligent pressure transmitters that work with computer control systems provides timely information on pressure, differential pressure, flow, and other information, effectively improving production efficiency and reducing production losses.

Common pressure measurement targets include pulp pipes, drying cylinders, steam-water separators, dewatering screws, and pressure screens. The measured media are often highly viscous and prone to scaling, including pulp, white water, chemicals, and coatings. Sino-Inst offers intelligent pressure transmitters and differential pressure transmitters that can be integrated with control systems.

Featured Pressure Transmitters for Paper Mill Slurry Wastewater

More Featured Water Flow Measurement Solutions

Measuring parameters such as flow, level, and pressure involved in wastewater treatment in the paper and pulp industry is crucial to the entire wastewater treatment process. Adjusting and managing these parameters can reduce energy consumption and ease worker workload, playing a crucial role in the smooth operation of paper mills.

Sino-Inst’s measurement and control instruments are widely used in paper mill slurry wastewater treatment systems in various countries. If you have any questions, please feel free to contact us!

-1.jpg)