When it comes to flow measurement, understanding the distinction between mass flow rate and volumetric flow rate is crucial. Both concepts are widely used in various industries, but they differ in several aspects. We’ll explore the key differences between mass flow rate and volumetric flow rate, examine the factors that affect flow rate conversions, and walk you through the conversion process step by step.

Defining Mass Flow Rate and Volumetric Flow Rate

What is Mass Flow Rate?

Mass flow rate refers to the mass of a fluid (Gas-Liquid-Powder) passing through a specific cross-sectional area per unit time. It focuses on the weight, not the volume, of the flowing medium.

Common units:

The common symbol for mass flow rate is ṁ. The SI unit for mass flow rate is kg/s. Other commonly used units include:

- Kilograms per second (kg/s): International standard

- Tons per hour (t/h): Industrial production

- lbs per hour (lb/h): US industry

- Ggrams per minute (g/min): Mass flow control

| From\To | kg/s | kg/h | t/h | lb/h |

| 1 kg/s | 1 | 3600 | 3.6 | 7936.6 |

| 1 t/h | 0.278 | 1000 | 1 | 2204.6 |

Our Sino-Inst mass flow meters can directly display mass flow rates in units such as g/h, kg/h, t/h, g/m³, kg/m³, and t/m³.

The Importance of Mass Flow Rate

In many industries, mass flow rate is crucial for ensuring accurate measurement and control of processes.

- Mass flow rate measurement eliminates inaccuracies caused by the physical properties of gases or fluids. Changes in temperature or pressure can affect volumetric flow rate.

- Many processes in the chemical, pharmaceutical, and food industries are quality-dependent. Chemical reactions depend on the quality of reactants or ingredients and must be added at the correct mass ratio.

- In trade transfer applications, the quality of exchange fluids determines their price, especially in the oil and gas industry.

- Gas mass flow rate is just as important as liquid mass flow rate. Gas mass flow rate ensures a stable gas supply that meets process requirements during production. This is applicable to gas proportioning in semiconductor manufacturing, reaction condition control in chemical production, and sterile gas supply in the pharmaceutical industry.

- Furthermore, mass flow rate monitoring of solid powders allows for tracking material consumption and output, enabling data statistics and production process control.

Featured Mass Flow Meters

What is Volumetric Flow Rate?

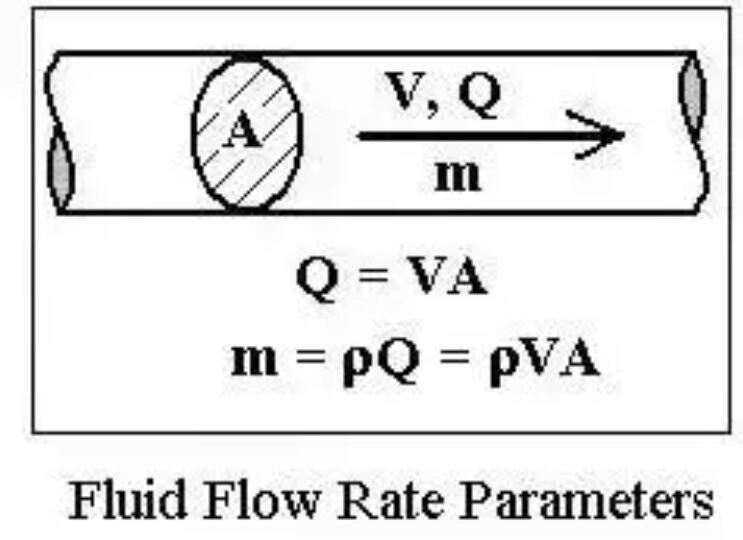

Volumetric flow rate, on the other hand, measures the volume of fluid passing through a given cross-sectional area per unit time. It focuses on the volume of the medium flowing through, not its weight.

Common Units:

Common symbols for volume flow rate are Q and V. The SI unit for volume flow rate is m³/s.

Common Units for Volumetric Flow Rate:

- Cubic meters per hour (m³/h): International standard, Chinese industrial standard

- Cubic meters per second (m³/s): Hydraulic engineering

- Liters per minute (L/min): Laboratory equipment

- Gallons per minute (GPM): US and UK industrial system

- Cubic feet per minute (CFM): US HVAC industry

- Barrels per day (bbl/d): Petroleum industry

| From\To | m³/h | L/min | GPM(USA) | CFM |

| 1 m³/h | 1 | 16.67 | 4.4 | 0.589 |

| 1 L/min | 0.06 | 1 | 0.264 | 0.0353 |

| 1 GPM(USA) | 0.227 | 3.785 | 1 | 0.134 |

| 1 CFM | 1.699 | 28.32 | 7.48 | 1 |

The Importance of Volumetric Flow Rate

Volumetric flow rate is essential for sizing equipment, monitoring fluid flow, and assessing system performance.

- First, volumetric flow rate measurement is less expensive than mass flow rate measurement. Therefore, volumetric flow rate has a wider range of applications.

- Monitoring the volumetric flow rate of water in water treatment and municipal water pipelines can help conserve water and prevent leaks.

- By monitoring the volumetric flow rate of diesel and gasoline consumption, cost calculations and trade transactions can be performed.

- In chemical plants, monitoring the volumetric flow rate of chemical fluids, such as sulfuric acid and alcohol, allows for understanding the production process and optimizing efficiency.

- Monitoring the volumetric flow rate of gases, such as nitrogen, helium, and oxygen, provides energy consumption data, thereby optimizing energy utilization and reducing production costs.

Featured Volumetric Flow Meters

Key Differences between Mass Flow Rate and Volumetric Flow Rate

1. Factors Influencing Measurements

One of the main differences between mass flow rate and volumetric flow rate lies in the factors that influence their measurements. Mass flow rate is affected by the fluid’s density, while volumetric flow rate is influenced by the fluid’s compressibility and changes in temperature and pressure.

2. Measurement Devices

Mass flow meters and volumetric flow meters are used to measure mass flow rate and volumetric flow rate, respectively. Some common mass flow meters include Coriolis flow meters, thermal mass flow meters, and differential pressure flow meters. Volumetric flow meters, on the other hand, may include turbine flow meters, positive displacement flow meters, and ultrasonic flow meters.

3. Applications

Mass flow rate measurements are critical in applications where the fluid’s mass is vital, such as chemical reactions, combustion processes, and mass balancing. Volumetric flow rate measurements are more commonly used in applications where the fluid volume is important, like water distribution systems and HVAC systems.

Relationship between Volumetric Flow Rate and Mass Flow Rate

Theoretically, the mass flow rate and volumetric flow rate of a gas or liquid can be converted using the fluid’s density. This conversion assumes a constant fluid density. In reality, density is affected by temperature and pressure. For fluids or gases with varying temperature/pressure, you need to measure the density in real time. For gases, you may need to consider the ideal gas law or use a specific gas constant.

Mass flow rate can be directly measured using a mass flow meter, or it can be obtained by multiplying the volumetric flow rate by the accurate density.

Volume flow rate can be obtained by dividing the mass flow rate by the fluid density. Volumetric flow rate varies with temperature and pressure, while mass flow rate remains constant when temperature or pressure changes.

Read more about: What Is the Flow Rate?

Converting Volumetric Flow Rate to Mass Flow Rate

1. The Conversion Formula

To convert volumetric flow rate to mass flow rate, you need to multiply the volumetric flow rate by the fluid’s density:

Mass Flow Rate = Volumetric Flow Rate × Density

2. Factors to Consider

When converting volumetric flow rate to mass flow rate, keep in mind that fluid density can change with temperature and pressure variations. Therefore, you should consider the fluid’s specific properties and conditions when performing the conversion.

3. Practical Example

Imagine you have a volumetric flow rate of 10 m³/s for water at 20°C (68°F). To convert this to mass flow rate, you need to know the density of water at 20°C, which is approximately 998 kg/m³. Using the conversion formula:

Mass Flow Rate = 10 m³/s × 998 kg/m³ = 9,980 kg/s

More about: Relationship Between Pressure And Flow Rate: Key Insights. And How To Calculate Pressure From Flow Rate And Vice Versa.

How to Measure and Control Mass Flow Rates and Volumetric Flow Rates?

For measuring mass flow rate, a mass flow meter can be selected. For gases, a thermal mass flow meter can be used; for liquids, a Coriolis mass flow meter can be used. There are also dedicated powder flow meters for solid powders. Alternatively, a volumetric flow meter can be selected, and flow rate can be converted from density.

For measuring volumetric flow rate, a volumetric flow meter can be directly selected. For liquids, electromagnetic flow meters, turbine flow meters, and oval gear flow meters can be used. For gases, vortex flow meters can be used.

For controlling mass flow rate and volumetric flow rate, a suitable flow controller can be selected. Alternatively, a flow meter can be configured with a flow controller system.

We offer a variety of mass flow rate and volumetric flow rate measuring instruments for measuring and controlling the flow rate of gases and liquids. We can also customize flow measurement and control solutions according to your requirements.

Choosing the Right Flow Measurement Method

Before deciding whether to measure mass flow rate or volumetric flow rate, we recommend considering the following factors:

- Fluid: Do you need to measure a gas or a liquid? Gases are generally compressible and sensitive to temperature and pressure; is temperature and pressure compensation required?

- Process Parameters: What are the temperature and pressure of the medium? High temperature and high pressure will affect the selection of the flow meter.

- Pipe Diameter and Flow Range: Based on your pipe size, is the flow range that the flow meter can measure compatible with the flow range you actually need to measure? If not, can the pipe be changed?

- Volumetric Flow Rate or Mass Flow Rate More Important? For your monitoring purposes, is volumetric flow rate more critical, or is mass flow rate more important? You need to know what data you must obtain.

- Accuracy Requirements: Mass flow meters typically provide higher accuracy under dynamic conditions. Of course, other parameters should also be considered when selecting the most accurate flow meter.

- Cost and Maintenance: While volumetric flow meters are generally more economical and easier to maintain, their accuracy may not meet your project requirements. Mass flow meters, while highly accurate, have a higher initial cost.

Frequently

Asked

Questions

More Flow Measurement Solutions

Top Guide to CO2 Flow Meters

Ultrasonic Clamp on Flow Meter for Quick & Easy Measurements

What Is a 4 to 20 Milliamp Signal?

How to Choose the Right Heating Oil Flow Meter for Your Business

Top 3 Flow Meters for Oil

How to Choose the Right Oil Pressure Transmitter for Your Application

Understanding the key differences between mass flow rate and volumetric flow rate, as well as mastering the conversion techniques, is essential for professionals working in industries that rely on accurate flow measurements. This guide will help you enhance your knowledge of these critical concepts and improve the efficiency of your operations.

At Sino-Inst, we are an experienced manufacturer and supplier of flow meters and process control equipment, offering a wide range of products tailored to your specific needs. We manufacture and supply handheld devices to measure volumetric flow rate, such as handheld ultrasonic flow meters. We also produce online mass flow meters that measure mass flow rate meters with high accuracy. You can contact us to purchase flow meters online, and the goods will be delivered to your door via international express. We support customization and are committed to providing high-quality, reliable solutions for you.

-1.jpg)