Tuning fork level switches and detectors use tuning fork vibration technology to provide reliable level point detection. They provide upper and lower limit alarms and control of the material level. Suitable for liquids, powders, solid particles, etc.

Tuning fork level switches are not affected by media flow, disturbance, bubbles, foam, vibration, solid particles and adhesion, and are an ideal alternative to float switches.

Features of Tuning Fork Level Switch

Technical Parameters

| Temperature | Medium temperature | -20℃~+220℃ |

| Ambient temperature | -40℃~+70℃ | |

| Storage temperature | -40℃~+85℃ | |

| Ambient humidity | ≤95%RH | |

| Mmeasured media | Liquid, powder or granular solid | |

| Medium density | Solid ≥ 0.1g/cm³ | |

| Liquid ≥ 0.7g/cm³ | ||

| Solid particles | ≤10mm | |

| Liquid viscosity | <1000mm2/s | |

| Angle of repose | ≥200 | |

| Pressure Range | -0.1~+4.0MPa | |

| Material | Shell Material | Die cast aluminum alloy |

| Fork material | S304, S316 | |

| Connection method | Thread | G1/2”, G3/4”, G1”, Customized |

| Flange | Customer defined | |

| Sanitary chuck | 50.5mm, Customized | |

| Supply Voltage | DC24V AC220V 50Hz | |

| Output | Relay output | Load AC250V/4A DC60V/4A |

| Open collector (NPN) output | Load 400mA | |

| Open collector (NPN) output | Load 400mA | |

| Power consumption | AC power supply | 3W Max |

| DC power supply | 5W Max | |

| Electrical interface | M20*1.5 | |

| Protection level | IP65 | |

| Explosion-proof level | ExdIIBT1~6 ExdIICT1~6 | |

| Action time | 3S | |

| Vibration | Tuning fork vibration frequency | 300±50Hz |

| Environmental vibration level | V.L.4 Acceleration no greater than 1 g | |

Vibration Level Switches Applications

The tuning fork level switch can measure a variety of material levels and is also suitable for measuring medium-density solid powders or granules that can flow freely. If you are not sure about the applicability, you can contact our technical engineers for confirmation.

- Power plant: coal pile, raw coal bunker, fuel bunker, water storage tank, exhaust gas purification tank, bunker pump, fly ash, ash storage, oil tank, etc.;

- Oil field: crude oil or finished oil storage tank, three-phase separator, sedimentation tank, sewage tank and oil-water interface, drilling mud tank, etc.;

- Chemical industry: detection of polyester, spandex, acid, alkali, crude oil distillation tower, raw material and intermediate bunker, reaction tank, ammonia tank, solid bunker, separator, etc.;

- Metallurgy: ore bunker, ore crusher, raw material bunker, auxiliary material bunker, blast furnace, alumina powder bunker, electrolytic cell buffer tank, etc.;

- Cement: stone bunker, raw material bunker, cement bunker, coal powder bunker, slag storage bunker, etc.;

- Papermaking: raw material bunker, storage tower, drying drum, chemical material storage bunker, etc.;

- Water treatment: reservoir, sewage tank, water treatment tank, sedimentation tank, deep well, drinking water network chromium, etc.;

- Flour mill: detection of flour and wheat grain level;

- Boiler plant: Detect drum water level and other pressure vessel liquid levels;

- Feed mill: detect soybean meal level;

- Glass mill: detect quartz sand and broken glass level;

- Construction machinery: detect cement silo level;

- Foundry machinery: detect sand level;

- Hydraulic machinery: detect lubricating oil level;

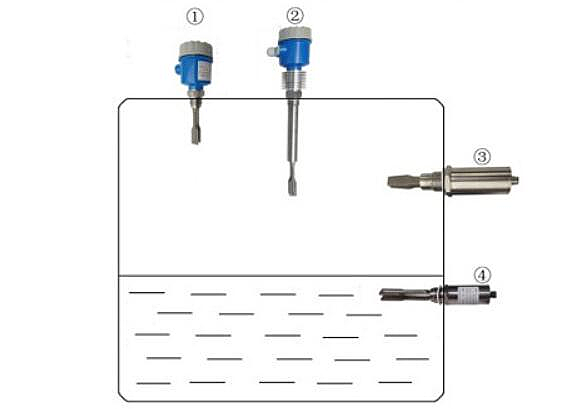

Featured Tuning Fork Level Switches Types

Standard thread connection Tuning Fork Level Switch

Standard thread connection Tuning Fork Level Switch Standard threaded connection Tuning Fork Level Switch with heat sink

Standard threaded connection Tuning Fork Level Switch with heat sink Standard flange connection Tuning Fork Level Switch

Standard flange connection Tuning Fork Level Switch Standard sanitary clamp connectionTuning Fork Level Switch

Standard sanitary clamp connectionTuning Fork Level Switch Standard thread connection M12 aviation plug Tuning Fork Level Switch

Standard thread connection M12 aviation plug Tuning Fork Level Switch Standard Hygienic Connection Hirschmann Connector Tuning Fork Level Switch

Standard Hygienic Connection Hirschmann Connector Tuning Fork Level Switch Small threaded Hirschmann connector Tuning Fork Level Switch

Small threaded Hirschmann connector Tuning Fork Level Switch Small threaded connection M12 aviation plug Tuning Fork Level Switch

Small threaded connection M12 aviation plug Tuning Fork Level Switch

Tuning Fork Level Switch Working Principle

The tuning fork level switch is a new type of level control switch. It mainly relies on the tuning fork to measure the level height through the vibration principle.

The working principle of the tuning fork level controller is to make the tuning fork vibrate at a certain resonant frequency through a pair of piezoelectric crystals installed on the tuning fork base.

When not in contact with the material, the tuning fork produces free vibration at the resonant frequency (about 138Hz).

When the tuning fork contacts the material, the vibration amplitude of the tuning fork will be significantly reduced. The output signal amplitude of the piezoelectric detection device also decreases accordingly. The signal change is detected and analyzed by the intelligent circuit and a switch signal is output.

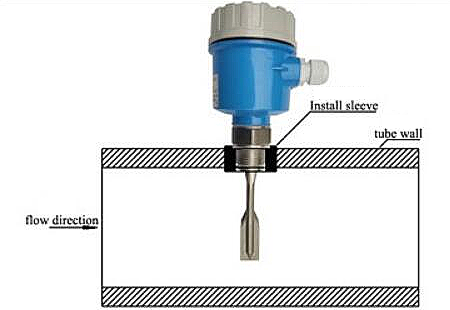

Tuning Fork Level Switch Installation

The tuning fork limit switch is usually installed sideways (on the side of the silo wall) to detect the upper and lower limits of the material level height on the side wall of the silo;

When it is inconvenient to open a hole on the side of the silo, it can be installed top-mounted (on the top of the silo). The position should be selected to avoid the impact of the material during feeding;

It can also be installed on the pipeline to prevent the pump from running without material.

When installing the sensor, insert it into the tank, clamp the hexagonal part of the upper part of the sensor thread with a wrench and tighten it. Be careful not to twist the junction box housing by hand, because the junction box housing and the probe rod will rotate during the tightening process. The connecting cable between the electronic unit and the sensor inside the housing has been connected at the factory. Tightening the housing hard will break the internal connecting cable.

During installation and construction, be careful not to subject the fork body to strong impact to avoid damage to the piezoelectric crystal.

The instrument sensor should try to avoid the impact of the material. When installed horizontally, the two parallel fork plates of the fork body should be perpendicular to the ground (at this time, the fork body direction mark is facing up or down). To ensure that the material can easily flow out from between the fork plates.

More Featured Industrial Level Transmitters and Measurement Solutions

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Water Level Pressure Transducers

- Typical Ultrasonic Level Sensor Applications and Advantages

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- 4 Wire – 3 Wire – 2 Wire Ultrasonic Level Transmitter

- Submersible Pressure Transducers for Liquid Pressure and Level Measurement

- Liquid Level Controllers and Switches for Industrial Tanks

- Difference Between Radar and Ultrasonic Level Transmitter

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

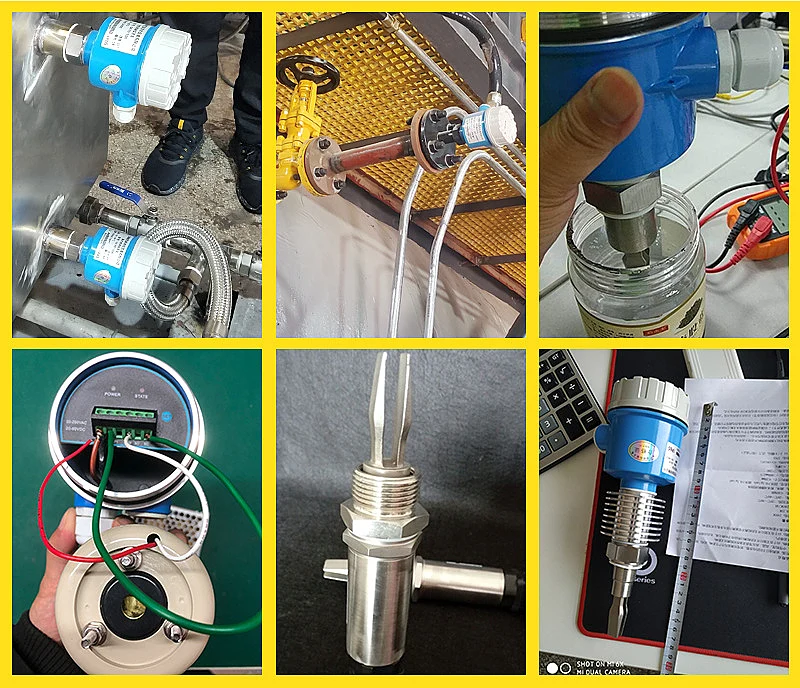

Vibration Tuning Fork Level Switches provide a reliable method to detect limit levels in various container types and pipelines. They are mainly used to measure the height of the material in the container, so that the back-end system can add (feed) or discharge (discharge) the container. They are common instruments in industrial production.

Sino-Inst’s Tuning Fork Level Switches are particularly suitable for measuring powdered objects and fine particles. They are widely used in the measurement of powdered and granular materials such as flour, salt, grains, beans, coal ash, dust, fine sand, chemical raw materials, and low-density foam particles in the silos of foam molding machines and blister machines.

If you need to purchase a tuning fork level switch, or need liquid level measurement and control, please contact our technical engineers!

Vibration Tuning Fork Level Switches for Liquid, Powder, Solid Particle

Tuning fork level switches and detectors use tuning fork vibration technology to provide reliable level point detection. They provide upper and lower limit alarms and control of the material level. Suitable for liquids, powders, solid particles, etc.

Product SKU: Vibration Tuning Fork Level Switches

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 199

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)